A U-shaped self-propelled wave power generation device

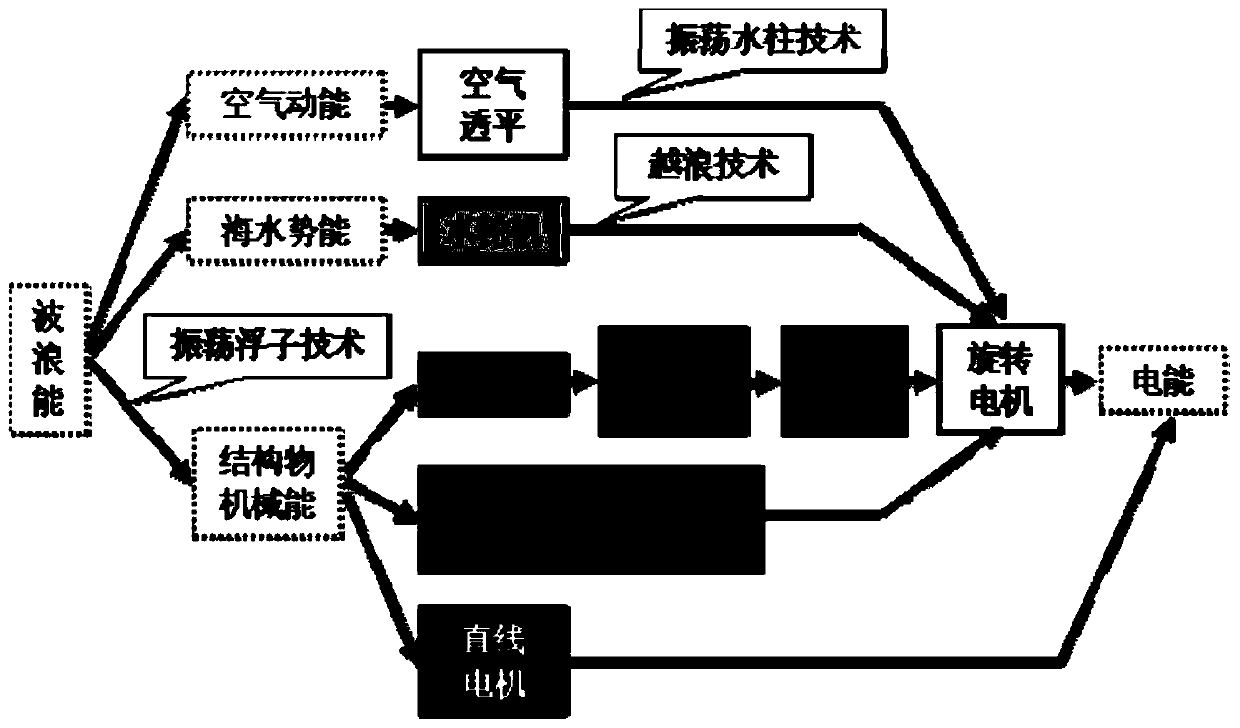

A power generation device and self-propelled technology, which is applied in ocean energy power generation, propulsion device engines, transportation and packaging, etc., can solve the problems of high price, complicated anchoring scheme, and high cost of ocean engineering, so as to reduce navigation resistance and draft , Improve the effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

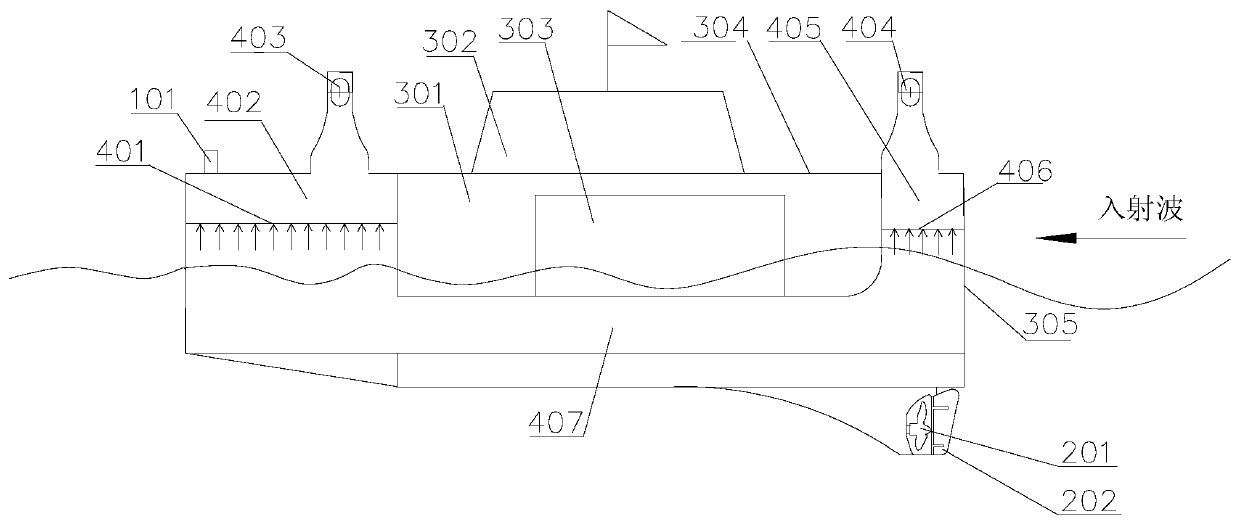

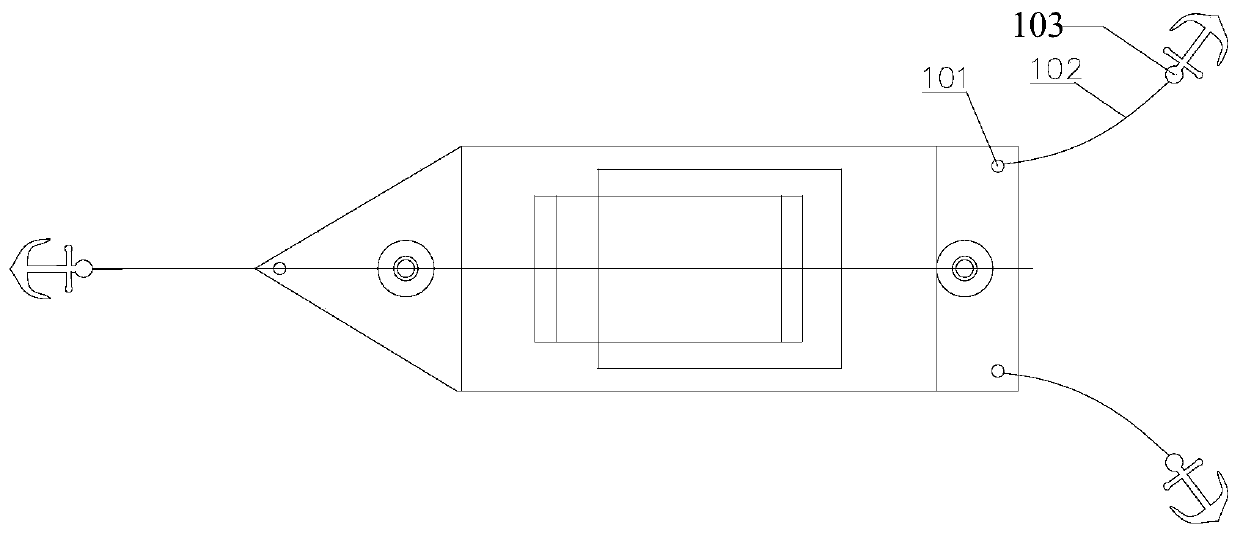

[0020] Such as Figure 2 to Figure 4As shown, a U-shaped self-propelled wave power generation device is composed of a hull, a wave energy collection and conversion mechanism, and a propulsion mechanism. The deck 304 is set on the upper part of the cabin 301, the cockpit 302 is set on the deck 304, the equipment room 303 is set inside the cabin 301, and the stern plate 305 is set at the tail of the cabin 301; the stern plate 305 is Pentagonal, the mooring system of the ship is composed of anchor piles 101, anchor chains 102 and anchors 103. There are 3 sets in total. There are electric motors, energy storage systems and pumping and drainage systems in the equipment room 104; , front triangular vertical tube 402, front air turbine generator set 403, rear air turbine generator set 404, rear quadrilateral vertical tube 405, rear water column 406 and pentagonal horizontal tube 407, front triangular vertical tube 402, pentagonal The horizontal tube 407 and the rear quadrangular ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com