V-shaped damping-wire clamp damping wire

A technology of damping wires and wire clips, which is applied in the field of damping wires, can solve problems such as the complexity of anti-vibration devices, achieve the effects of easy installation and maintenance, improved frequency response characteristics, and avoid damage or broken strands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

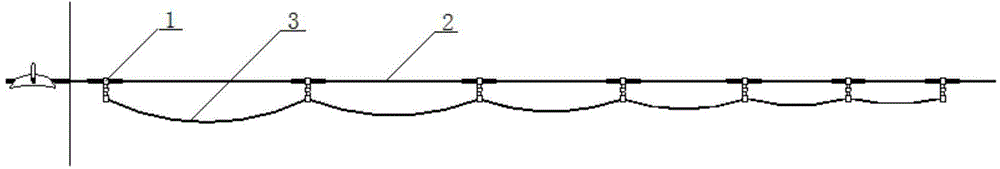

[0051] The first damping clamp 1 is installed on the overhead line 2 at a distance of 1m from the outlet of the tension clamp. The damping clamp 1 is suspended on the overhead line 2 through the clamp chuck 110, and the clamp cover 103 passes through the barrier. The pin 107 is tightly locked on the overhead line 2; the second damping line clamp 1 and the first damping line clamp 1 are installed symmetrically on the opposite side, that is, the line between the first damping line clamp 1 and the second damping line clamp 1 Clamp two 111 are respectively located on both sides of the overhead line 2, in this way, install the third V-shaped damping line clamp 1, the fourth V-shaped damping line clamp 1, etc.; finally, install the damping line 3 on the line clamp In the collet 111, the clamp gland two 105 is locked with the retaining pin 107.

Embodiment 2

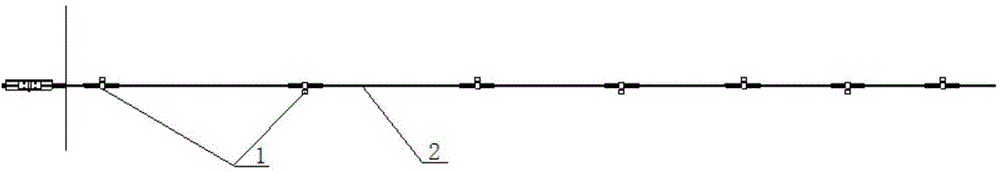

[0053] The first damping clamp 1 is installed on the overhead line 2 at a distance of 1m from the outlet of the tension clamp. The damping clamp 1 is suspended on the overhead line 2 through the clamp chuck 110, and the clamp cover 103 passes through the barrier. The pin 107 is tightly locked on the overhead line 2; the second damping line clamp 1 is symmetrically installed on the same side as the first damping line clamp 1, that is, the line between the first damping line clamp 1 and the second damping line clamp 1 Clamp two 111 are located on the same side of the overhead line 2, in this way, install the third V-shaped damping line clamp 1, the fourth V-shaped damping line clamp 1, etc.; finally, install the damping line 3 on the line clamp In the collet 111, the clamp gland two 105 is locked with the retaining pin 107.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com