A scale damping line

A technology of damping wires and scales, applied in the field of damping wires, can solve problems such as the complexity of anti-vibration devices, achieve outstanding anti-vibration performance, avoid damage or broken strands, and facilitate installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

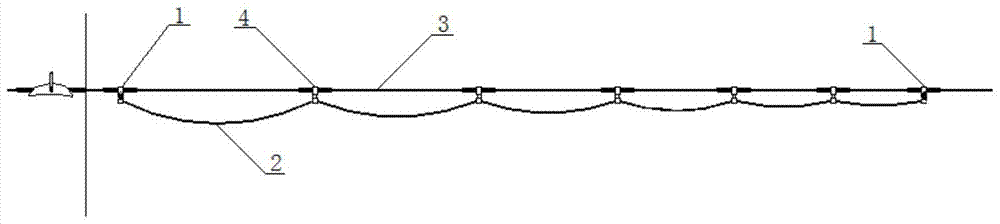

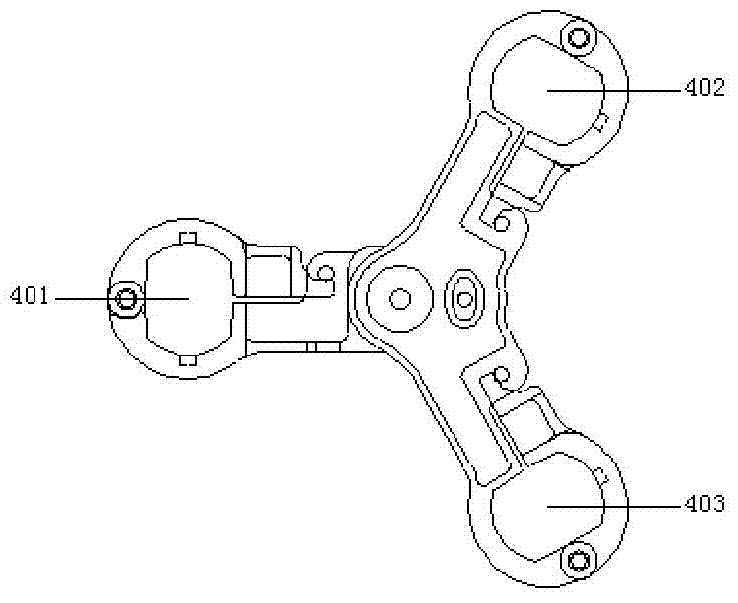

[0051] The first side damping line clamp 1 is installed at a place 1m away from the outlet of the suspension line clamp guard line or the tension line clamp of the fixed overhead line 3, one end of the first damping line 2 is installed on the first side damping line clamp 1, and the other One end is connected to the second chuck 402 of the first scale damping wire clamp 4, and the first chuck 401 of the first scale damping wire clamp 4 is clamped on the overhead wire 3. At this time, the second chuck 402 and the second The three chucks 403 are located on the same horizontal plane. The first collet 401 of the first scale damping wire clamp 4 is tightly locked on the overhead wire 3 by the first wire clamp gland 405 by the stop pin 406, and the damping wire is nested in the chuck holding groove of the wire clamp, and then The clamping cover is locked tightly by a stop pin.

[0052] One end of the second damping wire 2 is connected to the third clip 403 of the first scale dampin...

Embodiment 2

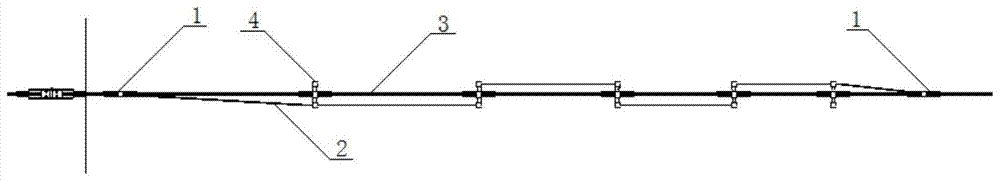

[0057] The first side damping line clamp 1 is installed 1m away from the outlet of the suspension line clamp guard line or the tension line clamp of the fixed overhead line 3, and one end of the first damping line 2 is installed on the first side damping line clamp 1, The other end is connected to the third clamp 403 of the first scale damping wire clamp 4, wherein the second clamp 402 of the first scale damping wire clamp 4 is clamped on the overhead wire 3, and the first clamp 401 It is located on the same level as the third chuck 403 .

[0058] One end of the second damping wire 2 is connected to the first clip 401 of the first scale damping wire clamp 4, and the other end is fixedly connected to the third clamp 403 of the second scale damping wire clamp 4 on the same side, namely The second damping line 2 and the first damping line 2 are respectively located on opposite sides of the overhead line 3 . The second scale damping wire clamp 4 is clamped on the overhead wire 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com