Preparation method of lysine carbocisteine

A technology of lysine carbocisteine and carbocisteine, which is applied in the field of preparation of lysine carbocisteine, which can solve the problem of affecting the quality and yield of the final product, poor particle size of the product, and caking of the final product, etc. problems, achieve consistent purity, uniform particles, and reduce environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a kind of preparation method of lysine carbocisteine, comprising the following steps:

[0020] Mixing L-lysine and carbocisteine aqueous solution, a salt-forming reaction occurs, and a salt-forming product system is obtained;

[0021] The salt-forming product system is spray-dried to obtain lysine carbocisteine.

[0022] In the present invention, unless otherwise specified, the components of all raw materials are commercially available products well known to those skilled in the art.

[0023] The invention mixes L-lysine and carbocisteine aqueous solution to generate a salt-forming reaction to obtain a salt-forming product system. In the present invention, the mass concentration of the carbocisteine aqueous solution is preferably 10%-50%, more preferably 20%-45%, and most preferably 30%-40%.

[0024] In the present invention, the molar ratio of L-lysine and carbocisteine in the aqueous carbocisteine solution is preferably 1:(0.8-1.2), ...

Embodiment 1

[0034] Mix 5.1 kg of carbocisteine (HPLC purity 99.9%) and 13.9 kg of a 30% L-lysine aqueous solution at a mass concentration of 13.9 kg, and carry out a salt-forming reaction at 25° C. under stirring for 2 hours to obtain a salt-forming product system.

[0035] Add the salt-forming product system into the hopper of the spray dryer, set the air inlet temperature to 100°C, the air outlet temperature to 80°C, and the atomization frequency to 1000rpm, start the spray dryer, turn on the induced draft fan, and start heating. When the tuyere temperature reached 100°C and the air outlet temperature reached 80°C, the atomizer and the peristaltic pump were turned on, and the rotating speed of the peristaltic pump was controlled to be 20rpm, and spray drying was carried out to obtain lysine carbocisteine 10kg (HPLC purity 99.9%), Yield 98%.

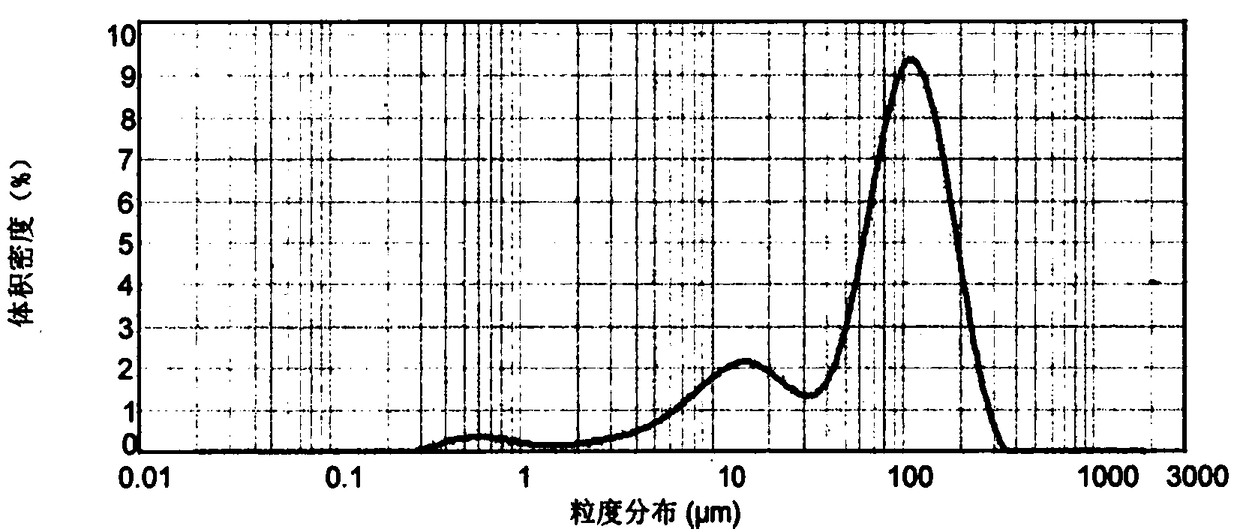

[0036] figure 2 Be the particle size distribution figure of described lysine carbocisteine, figure 1 For reference, the patent No. is the p...

Embodiment 2

[0038] Mix 5.1 kg of carbocisteine (HPLC purity 99.8%) and 13.9 kg of 30% L-lysine aqueous solution at a mass concentration of 13.9 kg, and carry out a salt-forming reaction at 25° C. under stirring for 2 hours to obtain a salt-forming product system.

[0039] Add the salt-forming product system into the hopper of the spray dryer, set the air inlet temperature to 120°C, the air outlet temperature to 100°C, and the atomization frequency to 2000rpm, start the spray dryer, turn on the induced draft fan, and start heating. When the tuyere temperature reached 120°C and the air outlet temperature reached 80°C, the atomizer and peristaltic pump were turned on, and the rotating speed of the peristaltic pump was controlled to be 30rpm, and spray drying was carried out to obtain 9.95kg of carbocisteine lysine (HPLC purity 99.8%) , yield 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com