Adhesive sticker laminating machine

A composite machine and glue technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of slow self-adhesive bonding, unreasonable structure setting, no shock absorbing device, etc., and achieve simple structure , reasonable design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. The embodiments of the present invention and all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

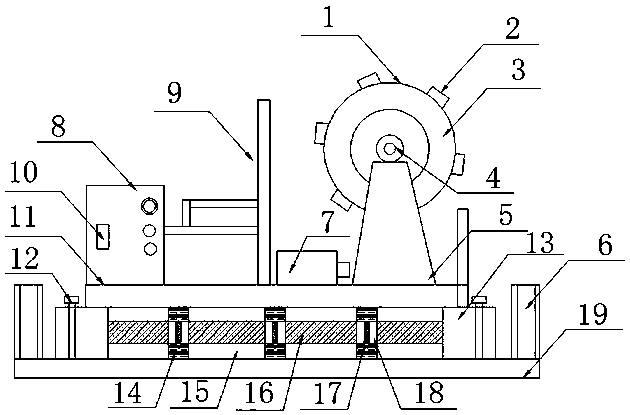

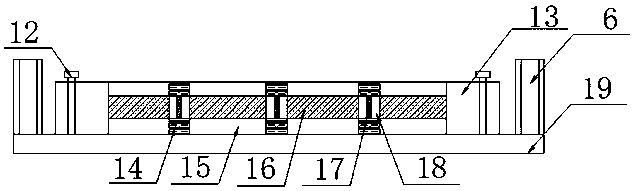

[0017] Such as Figure 1-2 As shown, the present invention provides a self-adhesive laminating machine, including a laminating machine body 1, a support base 2, a heat roller 3, a rotating shaft wheel 4, a support base 5, a baffle 6, a drive motor 7, a glue tank 8, and a support rod 9. Glue injection port 10, support plate 11, bolt 12, shock absorption device 13, shock absorption air plug 14, shock absorption block 15, shock absorption spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com