On-phase method for alternating current servo system capable of overcoming friction force influence

A technology of AC servo and friction force, applied in the field of phase contrast, can solve the problem of not considering the influence of friction force, etc., and achieve the effect of improving the calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

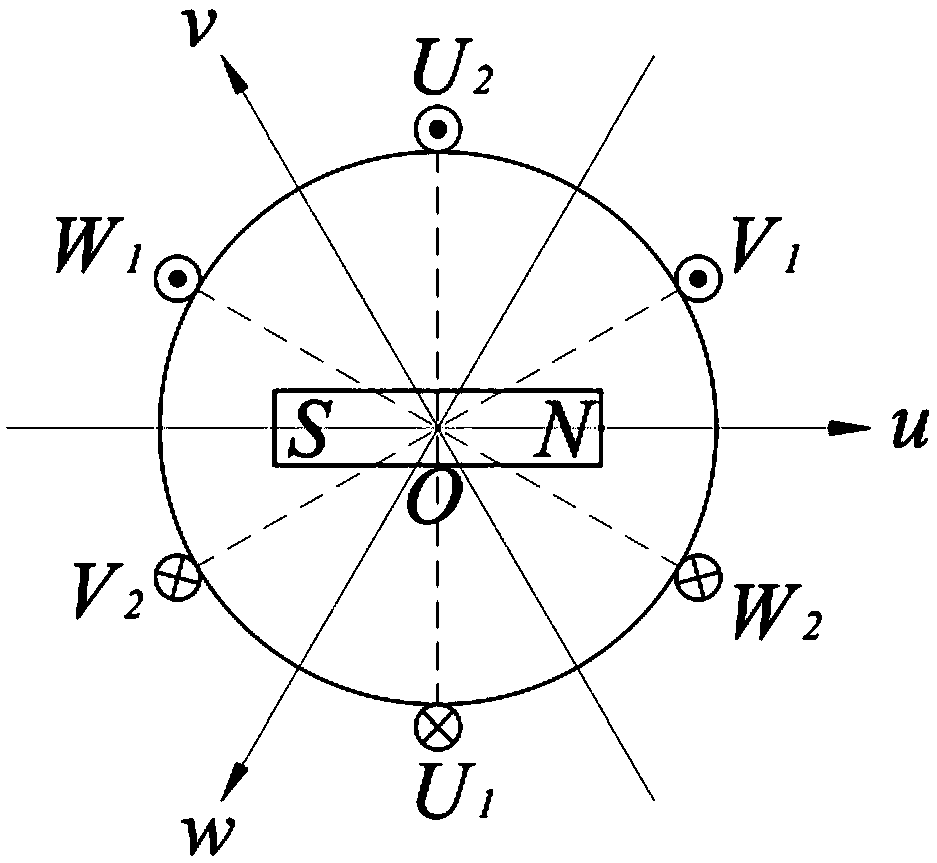

[0030] like Figure 5 and 6 As shown, the method for phase contrast of the AC servo system that overcomes the influence of the friction force disclosed by the present invention includes the following steps:

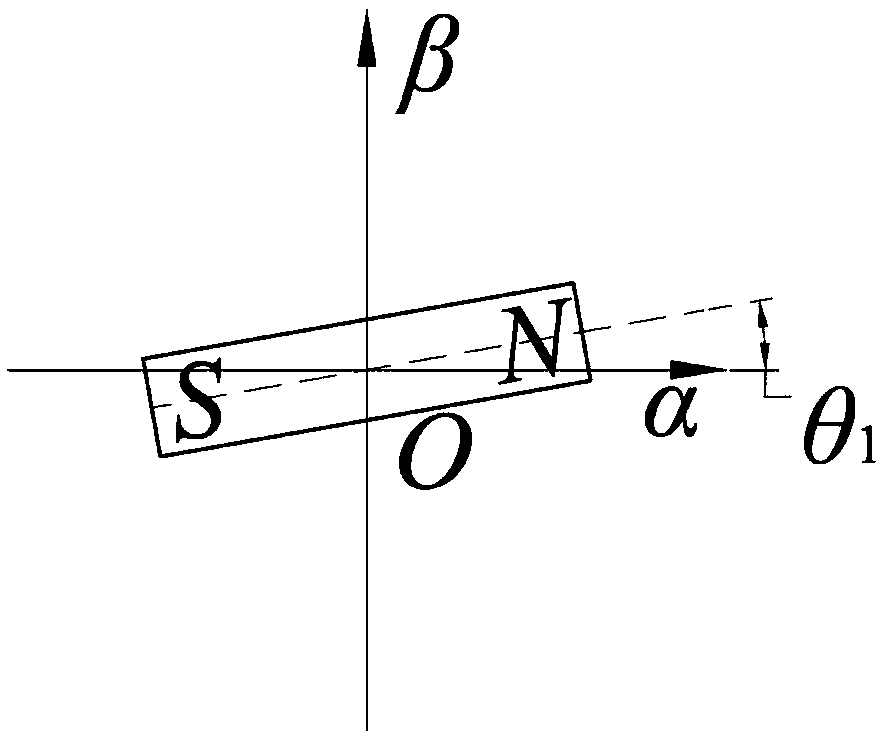

[0031] Step 1, establish the αβ coordinate system to compensate the influence of friction force, and set the magnetic pole N to be located above the α axis;

[0032] Step 2, start the phase comparison, the specific steps are:

[0033] Step 2.1, Setup Start SVPWM, the magnetic pole rotates clockwise from the initial position, and reaches the position where the magnetic pole N just passes the positive half-axis of the α-axis, that is Figure 5 The position shown in the figure in (1), where U N is the voltage corresponding to the rated current of the motor, t is the time variable of the rotation in this step, and its value range is 0≤t≤T 1 , T 1 is the duration of rotation for this step;

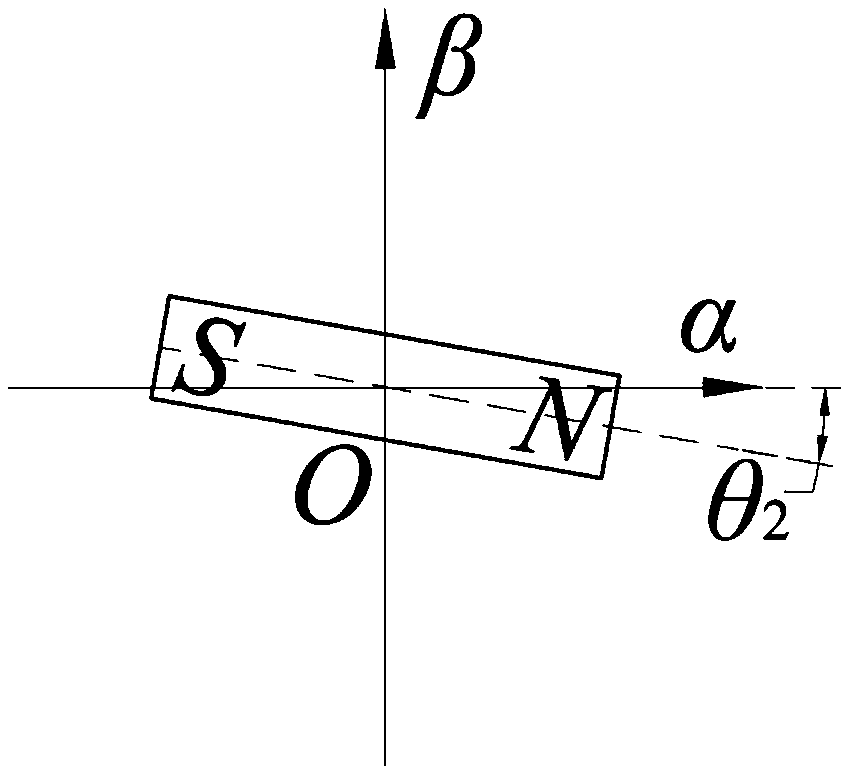

[0034] Step 2.2, Setup Start SVPWM, the magnetic pole rotates counterclockwise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com