Impact piezoelectric rotary motor

A rotary motor and impact technology, which is applied in the field of precision micro-drives, achieves the effects of compact structure, miniaturization, complex structure, difficult processing and mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

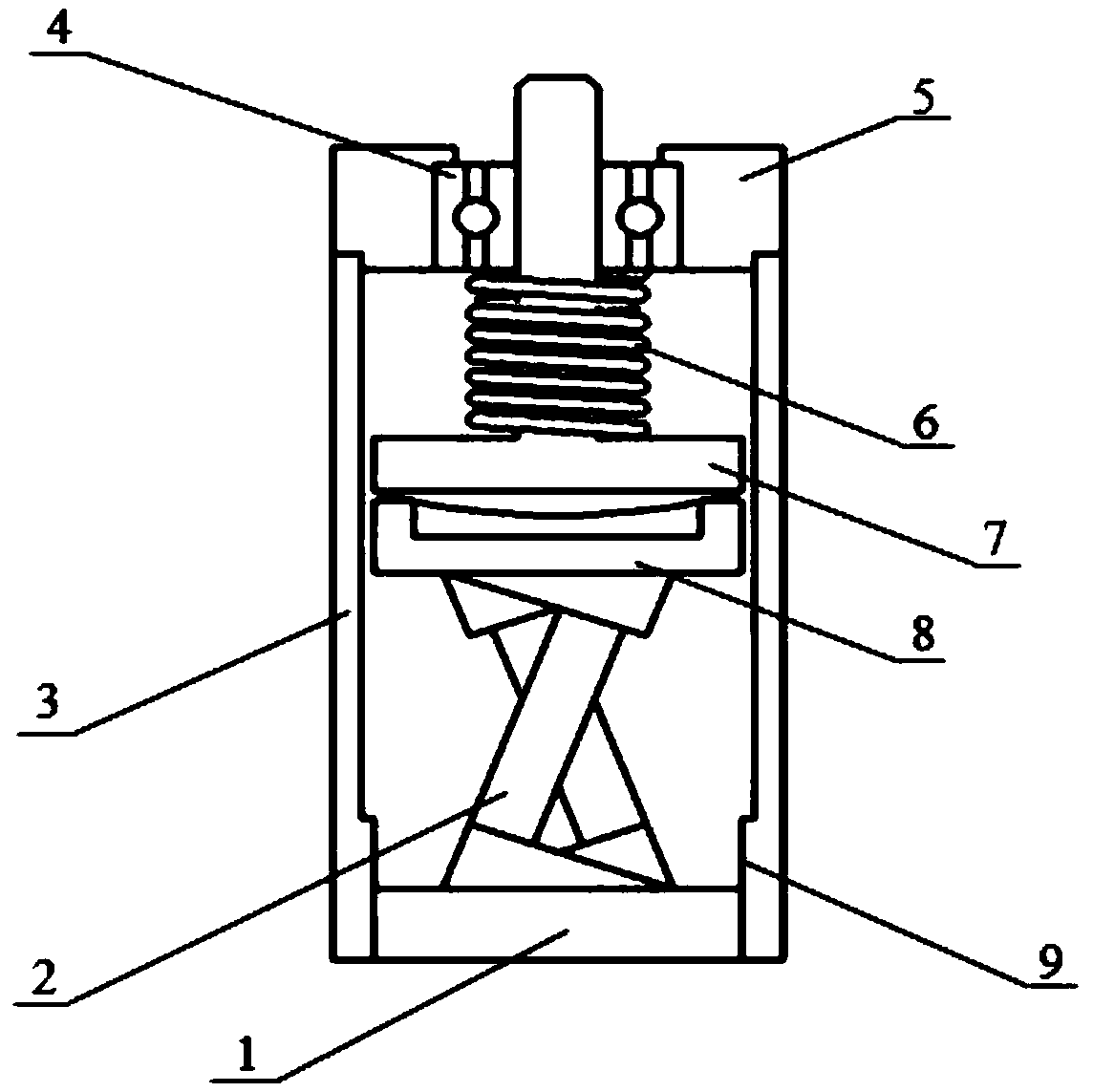

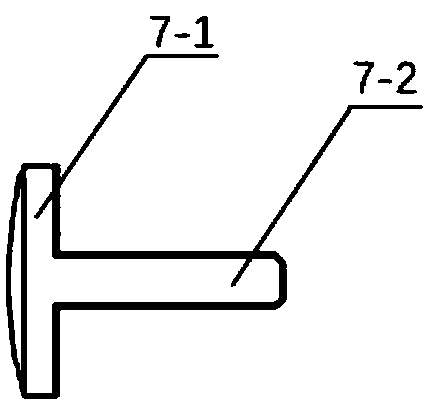

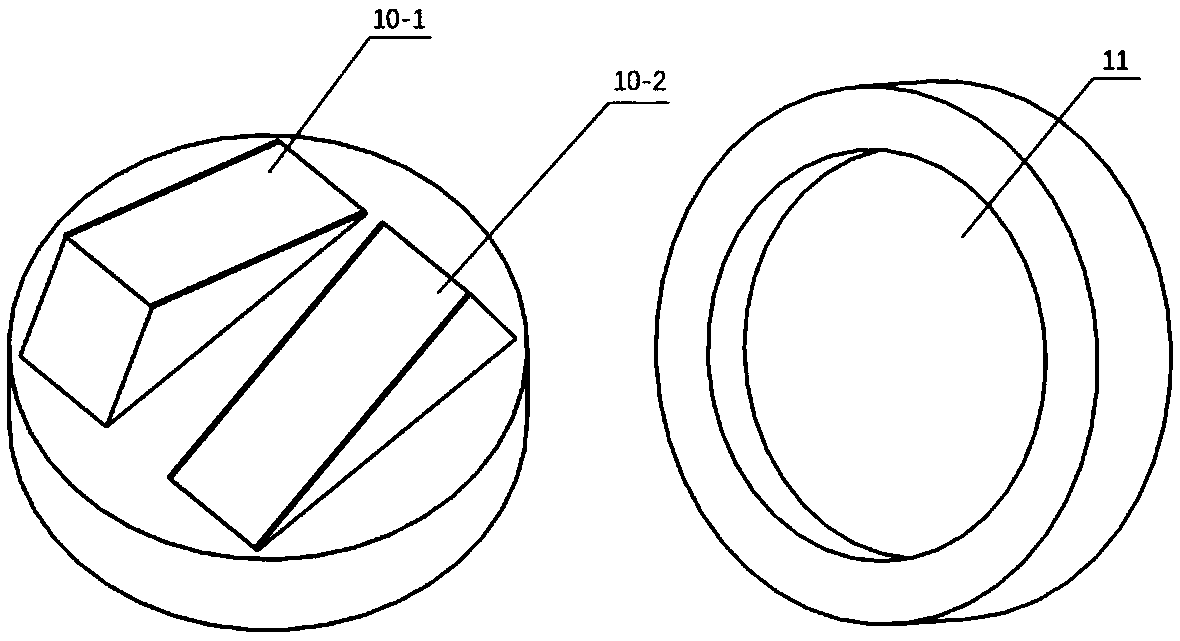

[0029] see Figure 1-Figure 4 , an impact piezoelectric rotary motor, including a piezoelectric stack 2 placed in a hollow cavity of a cylindrical sleeve 3, a vibration coupler 8 and a rotor 7; the bottom fixing plate 1 of the cylindrical sleeve 3 is provided with two Symmetrically distributed bosses with inclined surfaces, the bottom surface of the vibration coupler 8 is provided with bosses with inclined surfaces in a mirror-symmetrical manner; two piezoelectric stacks 2 symmetrical to the center line are arranged obliquely at the bottom of the cylindrical sleeve 3 Between the fixed plate 1 and the vibration coupler 8, the two ends of the piezoelectric stack 2 are respectively arranged on the top of the inclined surface of the boss; one end of the rotor 7 is the contact surface 7-1 which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com