Anti-knock bulletproof coating material and preparation method and application thereof

A coating material and bulletproof technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as the inability to meet the protection performance requirements of damage means, improve the ability to resist bullet penetration and structural rupture, and improve anti-knock performance. , the effect of slowing down the impact speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

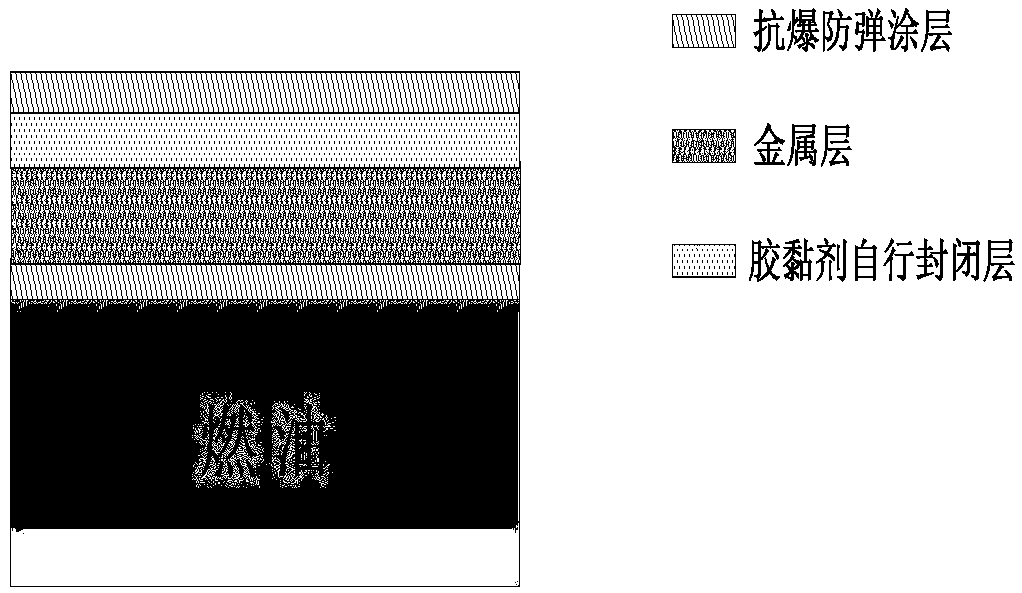

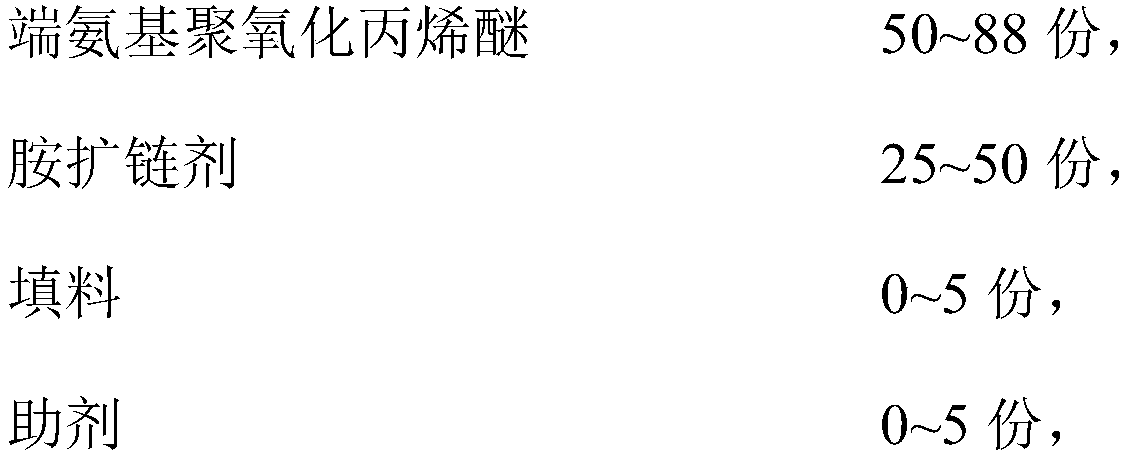

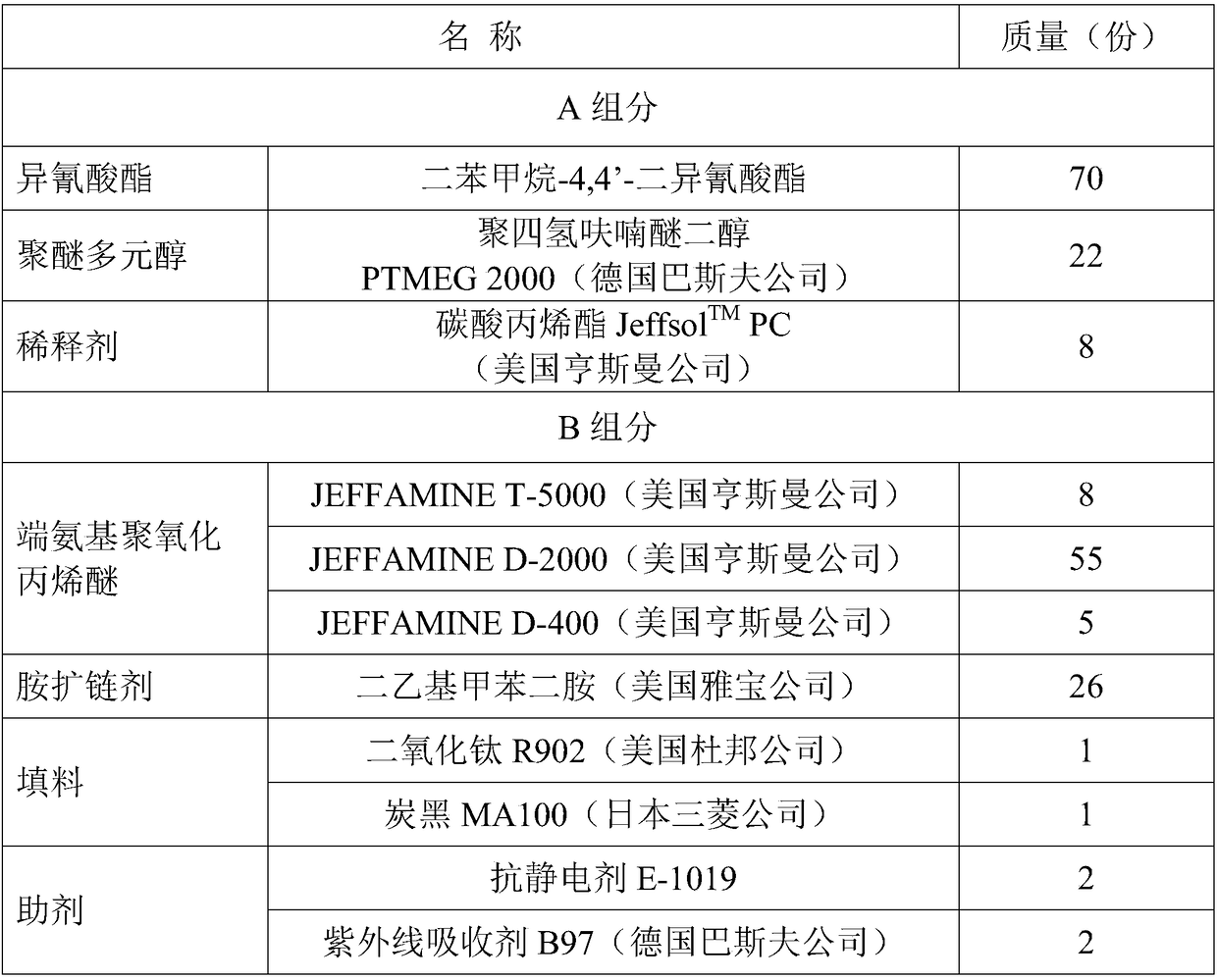

[0038] An anti-explosion and anti-ballistic coating material is composed of A component and B component, and its composition and mass parts are shown in Table 1.

[0039] Table 1 Composition of A component and B component

[0040]

[0041] A kind of preparation method of anti-explosion bulletproof coating material of the present invention, described method step is as follows:

[0042] (1) Add polytetrahydrofuran ether glycol PTMEG 2000 into the reaction kettle I protected by nitrogen, heat to 120°C under stirring, dehydrate under vacuum 0.085MPa for 1.2 hours, remove the vacuum, and add diphenylmethane after cooling down to room temperature -4,4'-diisocyanate, react at 95°C for 3.5 hours, cool down to below 60°C and add propylene carbonate JeffsolTM PC, get A component after stirring evenly.

[0043] (2) Add amino-terminated polyoxypropylene ether JEFFAMINE T-5000, amino-terminated polyoxypropylene ether JEFFAMINED-2000, amino-terminated polyoxypropylene ether JEFFAMINE D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com