Fuel environment-friendly additive and preparation method thereof

An additive and fuel technology, applied in the field of fuel additives, can solve problems such as affecting the normal operation of the engine, and achieve the effects of improving anti-knock performance, saving fuel, and increasing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The fuel additive of the present invention comprises following components:

[0033] Based on the total weight of the fuel additive as 100wt.%,

[0034] 1. Tert-butyl ferrocene: 18%;

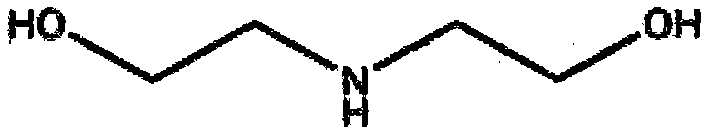

[0035] 2. Diethanolamine: 0.1%;

[0036] 3. Oleic acid: 16%;

[0037] 4. Solvent oil: 39.9%;

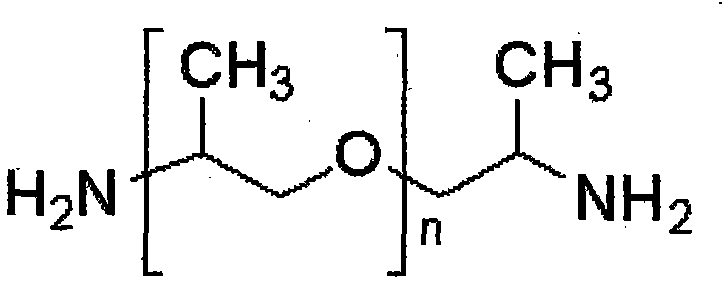

[0038] 5. Polyetheramine: 12%;

[0039] 6. Polyoxyethylene ether 8%;

[0040] 7. Polybutene 6%.

[0041] The preparation method is as follows: add 1.8kg of tert-butylferrocene and 3.99kg of solvent oil into the reaction device, stir for 10 to 20 minutes, then add 0.01kg of diethanolamine, 1.6kg of oleic acid, and 1.2kg of Polyether amine, 0.8 kg of polyoxyethylene ether, and 0.6 kg of polybutene, each of which was added, was stirred for 10 to 20 minutes, and after standing in the reaction device for 6 hours, the impurities were filtered, that is, the obtained fuel additive. The fuel additive was mixed with 9.99 tons of gasoline at a ratio of 1:1000 for experimental testing.

[0042] Acco...

example 2

[0044] The fuel additive of the present invention comprises following components:

[0045] Based on the total weight of the fuel additive as 100wt.%,

[0046] 1. Tert-butyl ferrocene: 20%;

[0047] 2. Diethanolamine: 0.1%;

[0048] 3. Oleic acid: 18%;

[0049] 4. Solvent oil: 31.9%;

[0050] 5. Polyetheramine: 12%;

[0051] 6. Polyoxyethylene ether 10%;

[0052] 7. Polybutene 8%.

[0053] The preparation method is as follows: add 2.0kg of tert-butylferrocene and 3.19kg of solvent oil into the reaction device, stir for 10 to 20 minutes, then add 0.01kg of diethanolamine, 1.8kg of oleic acid, and 1.2kg of Polyether amine, 1.0 kg of polyoxyethylene ether, and 0.8 kg of polybutene, each of which was added, was stirred for 10 to 20 minutes, and after standing in the reaction device for 6 hours, the impurities were filtered, that is, the described fuel additive. The fuel additive was mixed with 9.99 tons of gasoline at a ratio of 1:1000 for experimental testing.

[0054] Ac...

example 3

[0056] The fuel additive of the present invention comprises following components:

[0057] Based on the total weight of the fuel additive as 100wt.%,

[0058] 1. Tert-butyl ferrocene: 22%;

[0059] 2. Diethanolamine: 0.1%;

[0060] 3. Oleic acid: 20%;

[0061] 4. Solvent oil: 21.9%;

[0062] 5. Polyetheramine: 14%;

[0063] 6. Polyoxyethylene ether 12%;

[0064] 7. Polybutene 10%.

[0065] The preparation method is as follows: add 2.2kg of tert-butylferrocene and 2.19kg of solvent oil into the reaction device, stir for 10 to 20 minutes, then add 0.01kg of diethanolamine, 2.0kg of oleic acid, and 1.4kg of Polyether amine, 1.2 kg of polyoxyethylene ether, and 1.0 kg of polybutene, each of which was added, was stirred for 10 to 20 minutes, and after standing in the reaction device for 6 hours, the impurities were filtered, that is, the described fuel additive. The fuel additive was mixed with 9.99 tons of gasoline at a ratio of 1:1000 for experimental testing.

[0066] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com