A method of pressing composite blocks by using semi-coke and quicklime

A composite block and quicklime technology, applied in the direction of calcium carbide, carbide, etc., can solve the problems of unrealized industrial application, lack of production feasibility, and affecting the strength of block materials, so as to improve strength, reduce energy consumption, and apply good raw materials sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

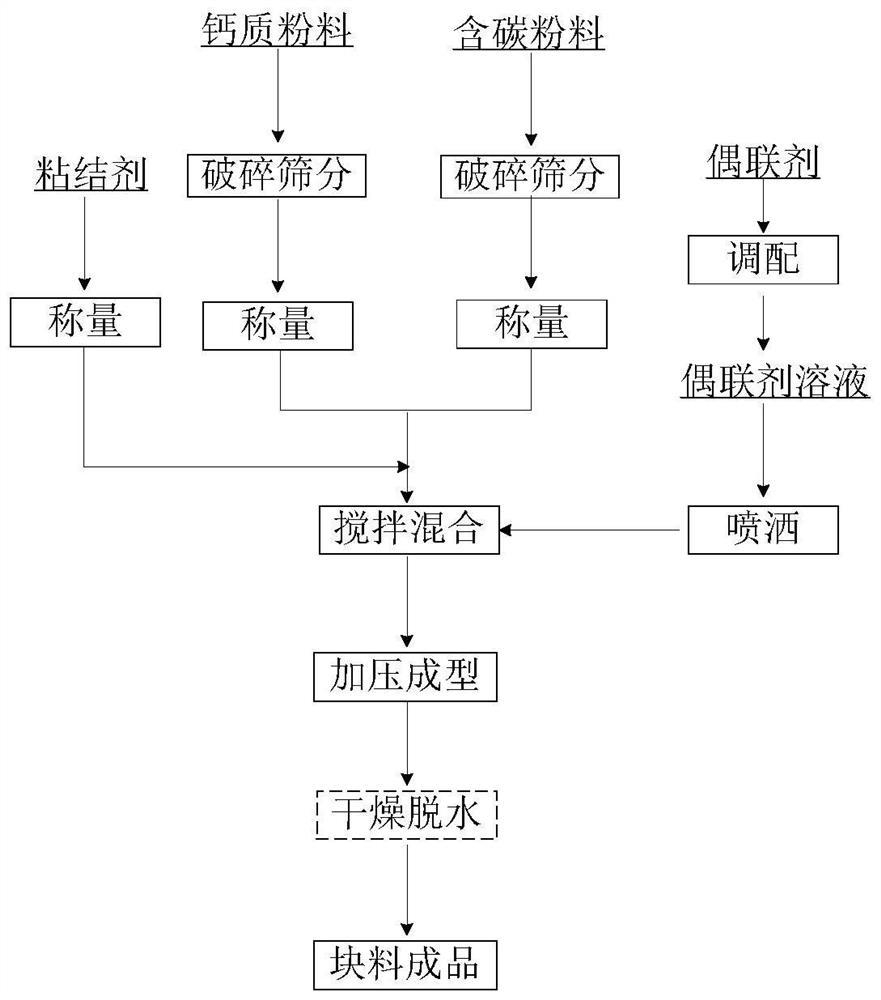

Method used

Image

Examples

Embodiment 1

[0039] Sodium benzenesulfonate solution with a mass fraction of 0.05% is used as a coupling agent, and calcium sulfate powder is used as a binder; 200 g of calcium hydroxide powder with a particle size of less than 1 mm and a particle size of less than 1 mm are respectively added to the mixing container. 84g of semi-coke powder, after the initial mixing of the two, add 28g of calcium sulfate powder to the mixture to continue stirring and mixing, and finally add 8g of sodium benzenesulfonate solution to the mixture and mix evenly until there is no lump in the mixture shape; put 20g of uniformly mixed powder into the forming mold, form it under the pressure of 20MPa and keep the pressure for 1min, after the mold is withdrawn, the forming raw material is obtained, and the obtained raw material is divided into several parts, referring to the cold strength of industrial briquette The detection method is to detect the cold strength of the obtained raw material; select a part of the r...

Embodiment 2

[0041] Kaolin powder was used as binder, and 0.5% papermaking wastewater lignin solution was used as coupling agent solution. Weigh 100g of calcium oxide powder, 250g of semi-coke powder, and 30g of kaolin powder respectively, stir and mix the two kinds of powder in a mixing container, and weigh 20g of the prepared coupling agent solution and add it evenly; 20g of powder is molded using a molding die under a pressure of 30MPa, and the pressure is maintained for 1min during molding. The detection method of the hot and cold strength of the obtained block is the same as that of Example 1. The average cold strength of the obtained block is 3800N / ball, and the average hot strength reaches 1050N / ball.

Embodiment 3

[0043] Use medium-temperature coal tar pitch powder as a binder, and 0.05% sodium benzenesulfonate solution as a coupling agent solution. Weigh 80g of calcium oxide powder, 250g of Shanbei long-flame coal powder, and 25g of medium-temperature coal tar pitch powder, stir and mix the three or two kinds of powder in a mixing container, and add 8g of the prepared coupling agent solution evenly. Weigh 20g of powder each time, use a molding die under a pressure of 30MPa, and hold the pressure for 1min during molding. The detection method of the hot and cold strength of the obtained block is the same as that of Example 1. The average cold strength of the obtained block is 6000N / ball, and the average hot strength reaches 960N / ball.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com