Automatic steel pipe feeding device

A technology of automatic feeding and steel pipes, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of long length, low work efficiency, hidden safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

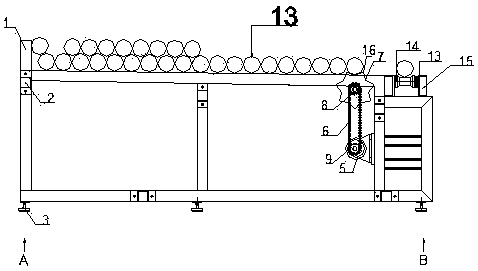

[0026] Provide specific implementation method of the present invention below in conjunction with accompanying drawing:

[0027] As shown in the figure, it includes a material storage system, a material transfer system, and a material delivery system. The material storage system stores and places steel pipes. The height of the storage rack 1 gradually decreases from the starting end A to the end B end. 1. Rolling from the starting end A to the end B under the action of gravity; the feeding system is connected to the end of the storage system, and the steel pipe 13 is transported to the processing device by the feeding system. The automatic feeding system of the present invention utilizes a distance sensor, which is an infrared sensor that can feel the distance between E and F, and the position of the distance sensor 11 is fixed, no matter which one the distance sensor 11 is in at the beginning. position, when an initial start signal is given to the motor 5, the dial shaft 12 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com