Milling machine

A milling machine and milling technology, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of lack of devices for collecting and processing debris and smoke, human injury, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

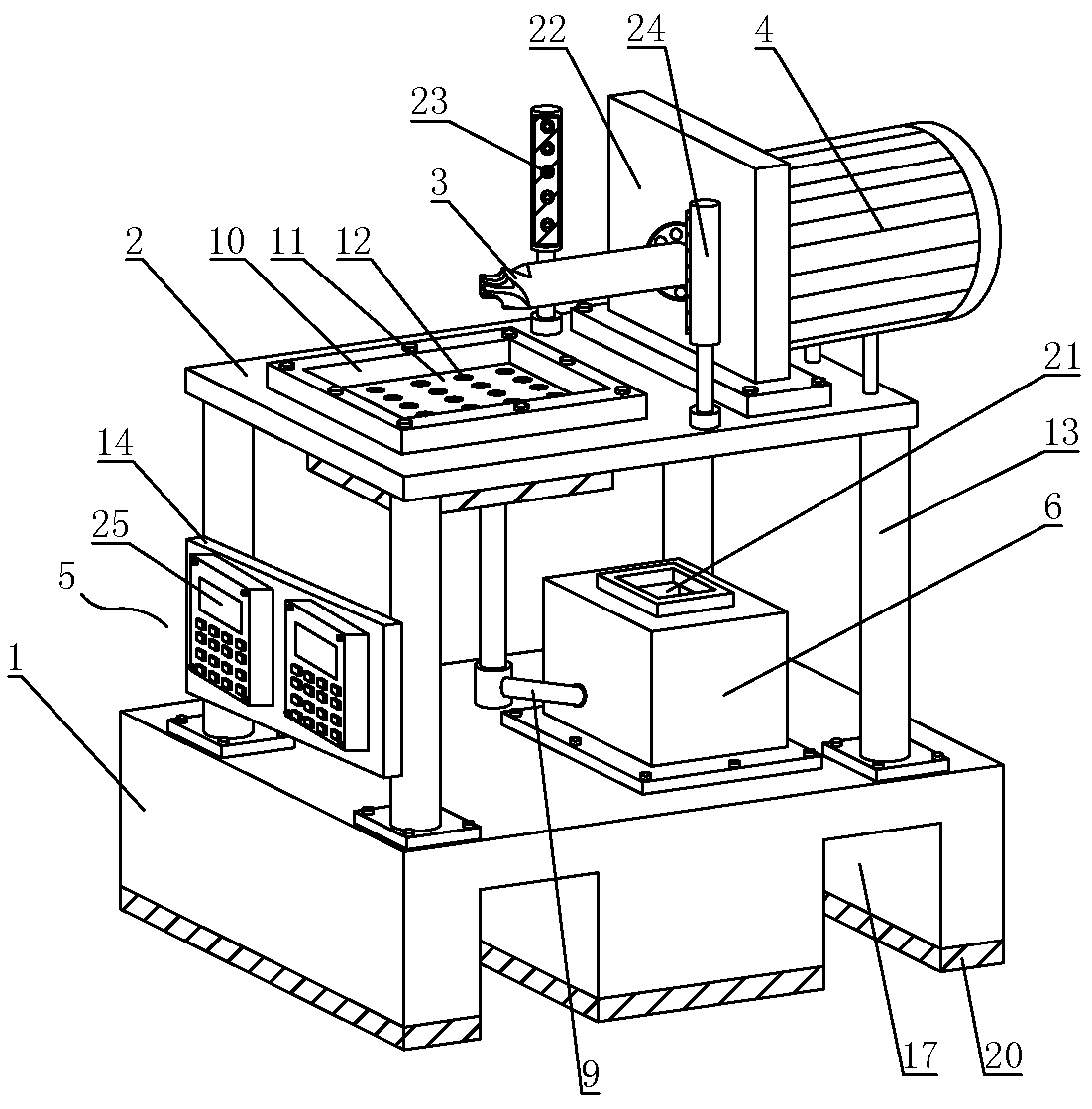

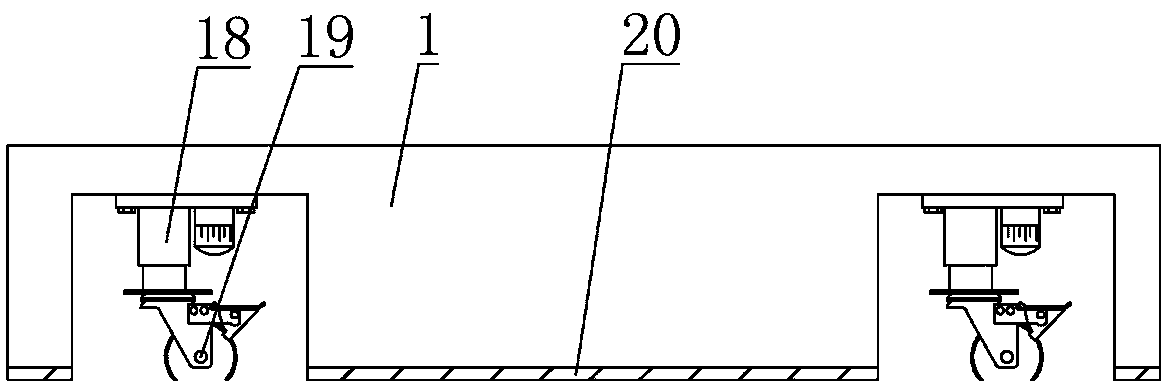

[0025] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a support seat 1, a limit groove 17 is opened on the lower surface of the support seat, an electro-hydraulic rod 18 is fixedly installed on the top end of the groove inside the limit groove 17, and a universal The wheel 19, the lower surface of the support seat 1 is fixedly equipped with a buffer pad 20, the support seat 1 and the buffer pad 20 are fixedly connected by bolts, and the buffer pad 20 is a member of rubber material;

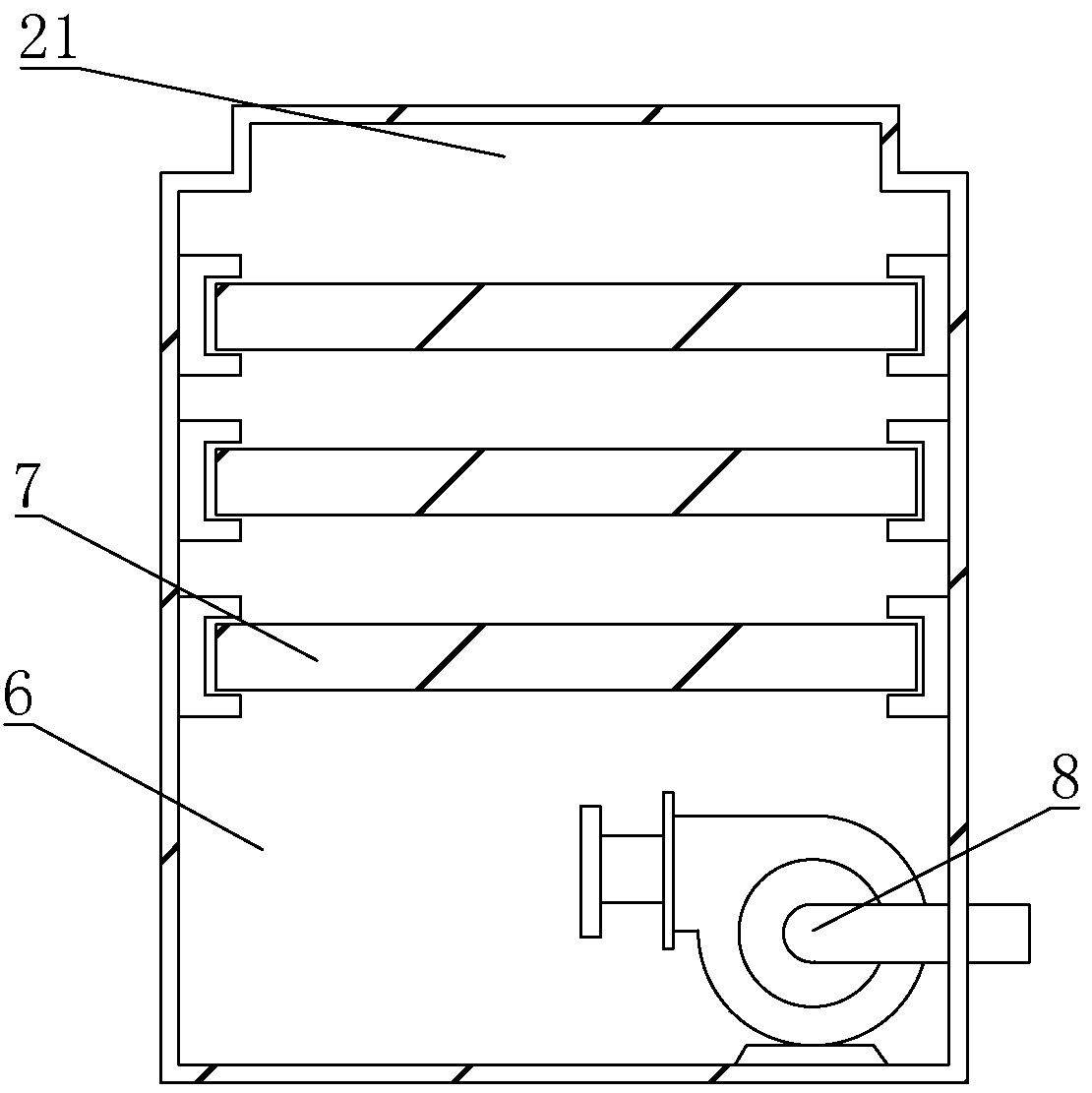

[0026] A milling table 2 is installed on the upper surface of the support base 1, and a milling cutter 3 is installed above the milling table 2. The non-head end of the milling cutter 3 is installed on the drive shaft of the electric drive device 4. A hollow dust removal box 6 is installed between them, and four columns 13 for supporting the milling table 2 are fixedly installed between the support base 1 and the milling table 2, and the bottom ends of each colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com