Intelligent ring-throwing cross-repair allocation system based on big data analysis

A smart ring and big data technology, applied in database management systems, database models, data processing applications, etc., can solve the difficulty of greatly improving the processing efficiency of a single device, increasing the difficulty of controlling the surface shape of neodymium glass components, and satisfying the requirements of neodymium glass. Component finishing requirements and other issues to achieve the effect of improving processing efficiency, improving hit rate, and improving qualified efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] For the ring polishing machine group consisting of 8 φ3m ring polishing machines, an intelligent cross-repair allocation system for the ring polishing machine group based on big data analysis is designed. The processing object is the neodymium glass element with a size of 810mm*460mm*40mm.

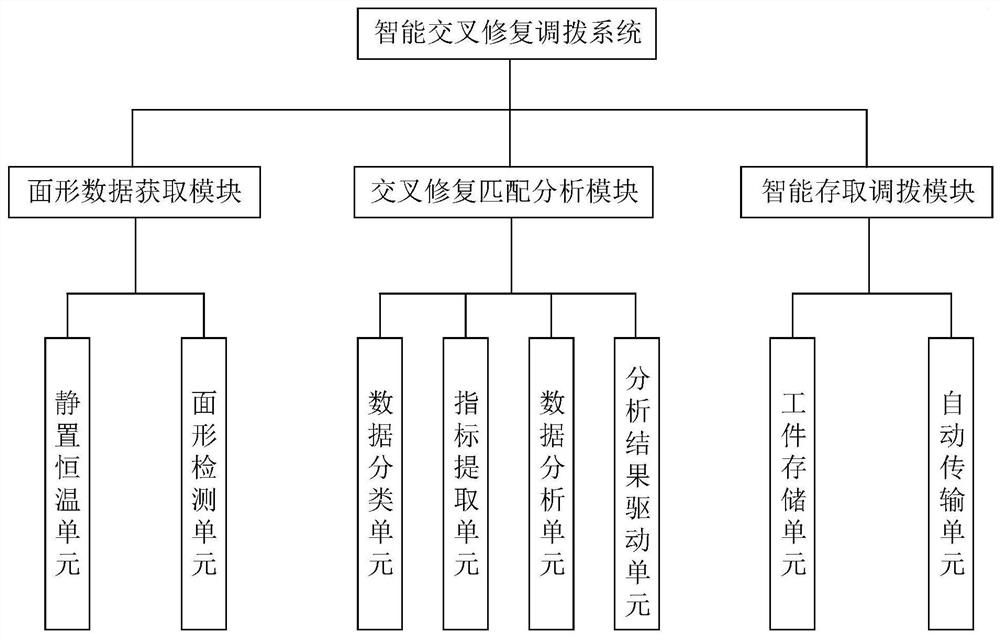

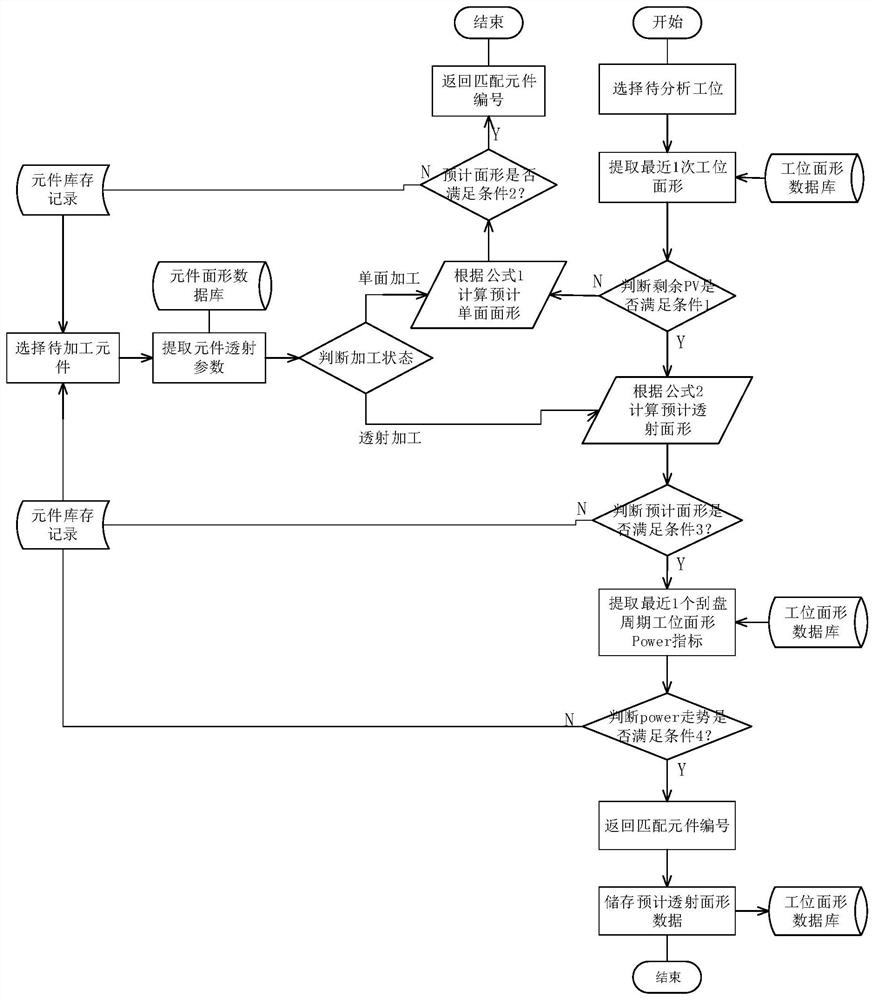

[0047] The intelligent cross-repair and allocation system for ring throwing machine clusters based on big data analysis includes a surface shape data acquisition module, a cross-repair matching analysis module, and an intelligent access and allocation module. The surface shape data acquisition module is composed of a static constant temperature unit and a surface shape detection unit; the cross repair matching analysis module is composed of a data classification unit, an index extraction unit, and a data analysis unit; the intelligent access allocation module includes a component storage unit and an automatic transmission unit.

[0048] More specifically, the surface shape data acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com