Industrial mechanical stirring and mixing device

A technology of mechanical stirring and mixing device, used in mixers, mixers, mixer accessories and other directions with rotating stirring devices, can solve the problems of poor mixing effect, large material particles, uneven mixing, etc., and achieve mobile parking Convenience, prolong service life and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

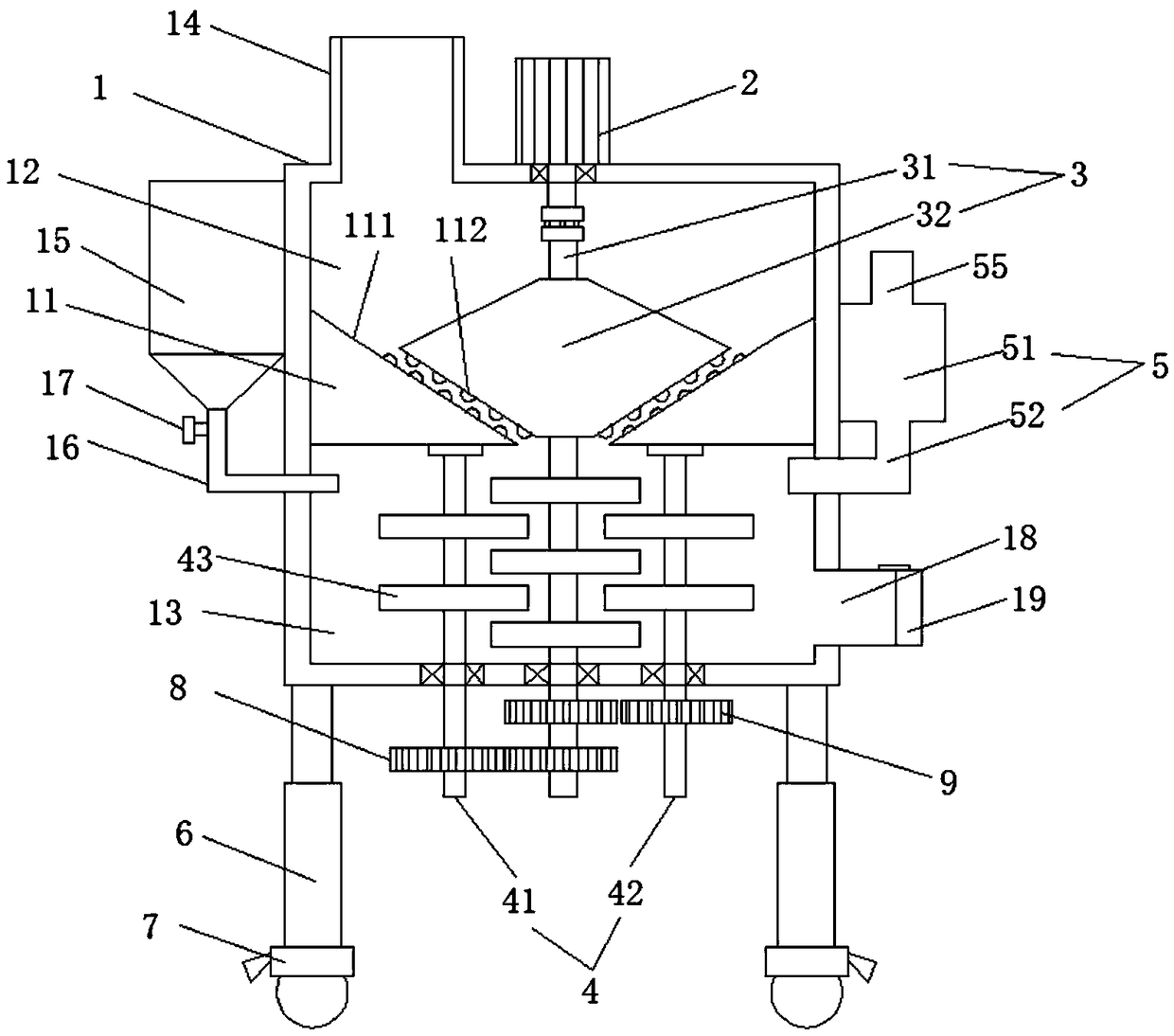

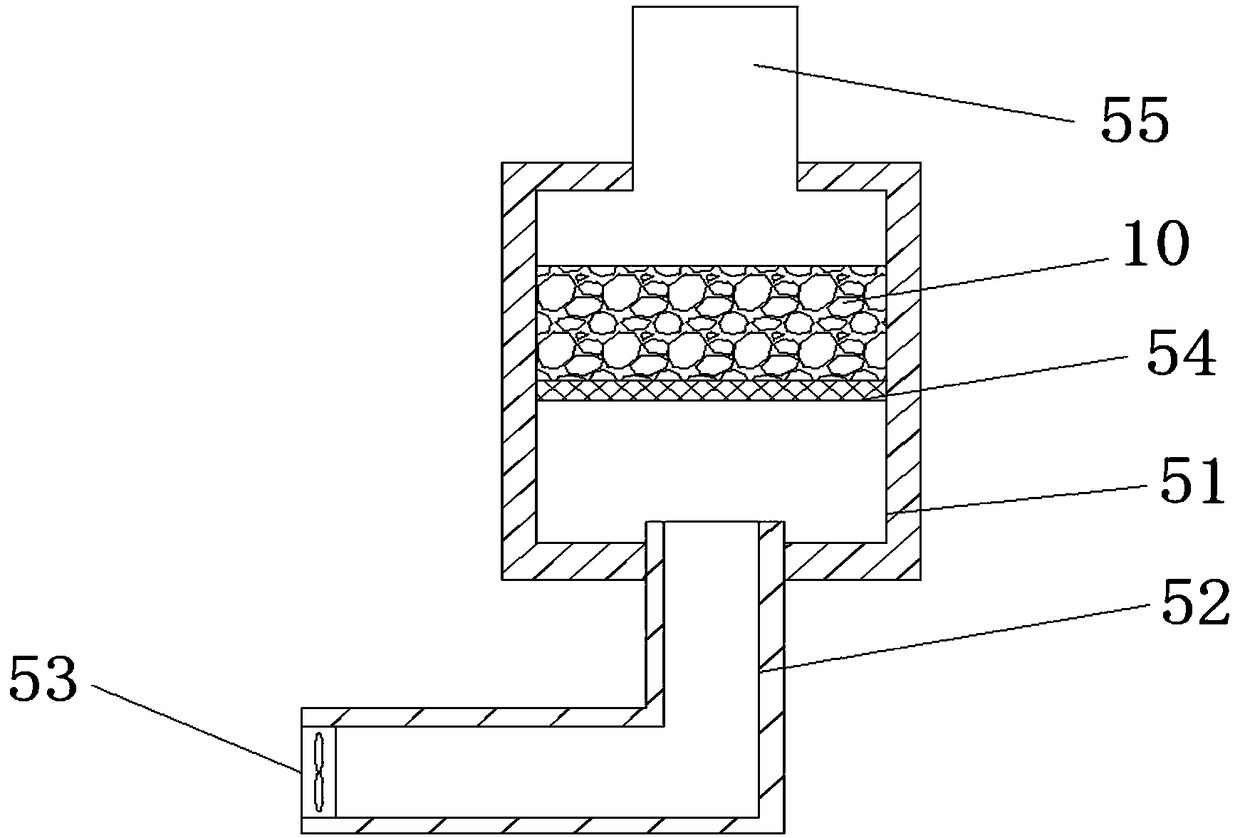

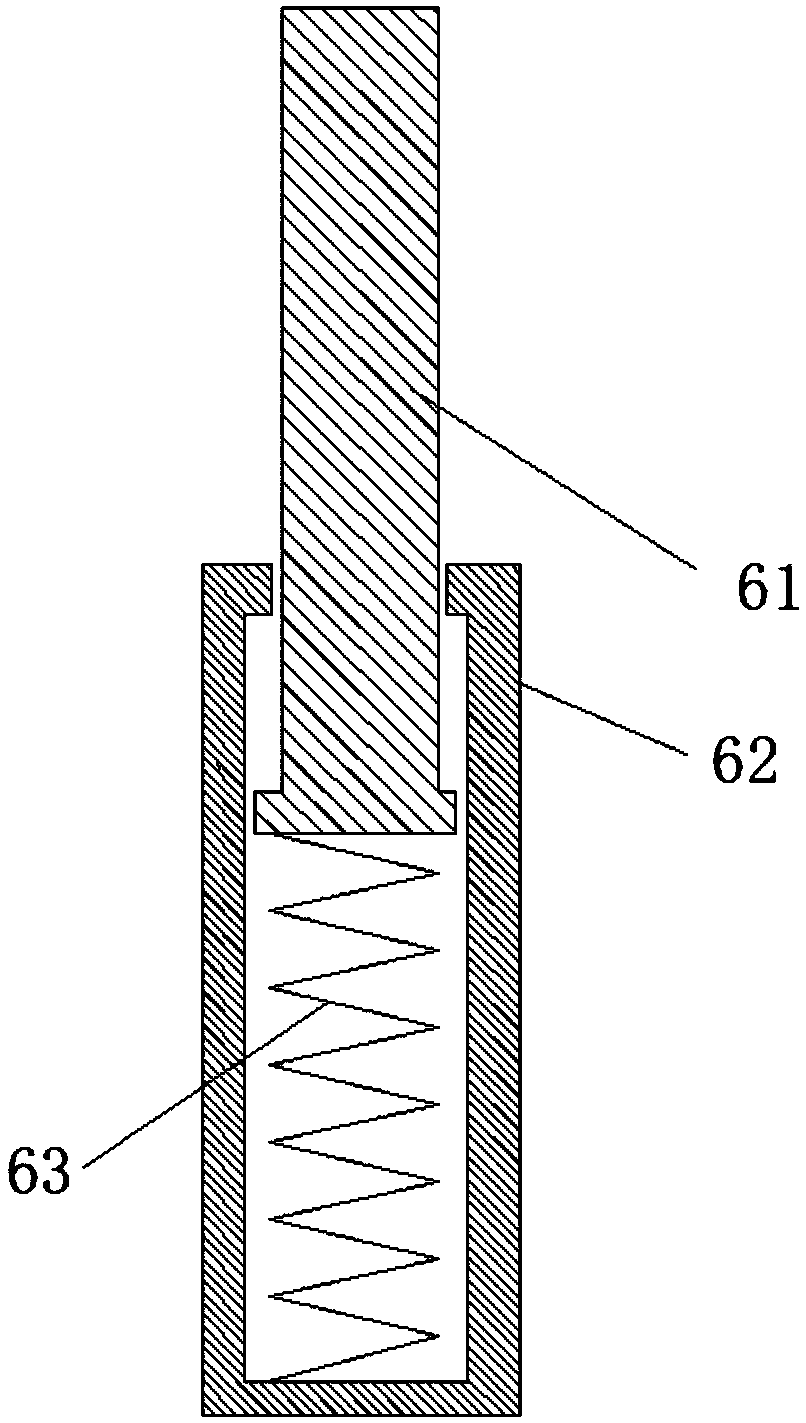

[0025] Such as figure 1 , figure 2 with image 3 A kind of industrial mechanical stirring and mixing device shown includes a tank body 1, a stirring motor 2, a grinding device 3, a stirring device 4 and a gas treatment device 5, and the inner circumference of the tank body 1 is fixedly provided with a grinding ring 11, The upper side of the grinding ring 11 in the tank body 1 is a grinding chamber 12, and the lower side of the grinding ring 11 is a stirring chamber 13. The stirring motor 2 is arranged on the upper end of the tank body 1 and the output shaft passes through the upper end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com