Blasting drilling machine

A technology for drilling machines and drill bits, which is applied to drilling equipment and methods, drilling equipment, and earthwork drilling and mining, and can solve the problems of large size, inconvenient movement, and potential safety hazards of blasting drilling machines, and achieves simple and convenient structure. Effect of moving and stopping, reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

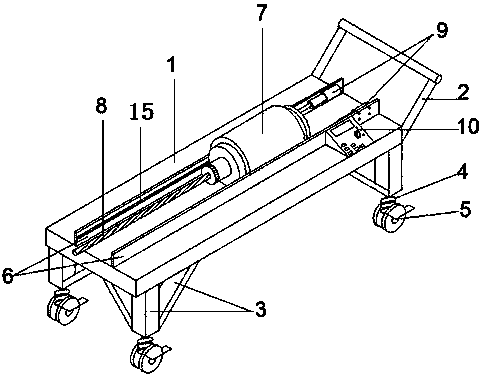

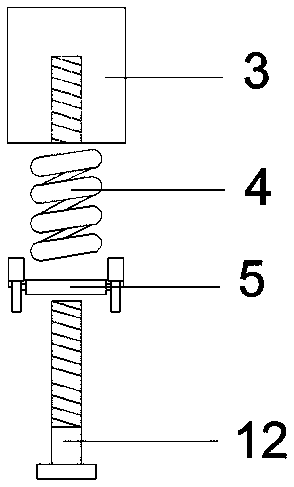

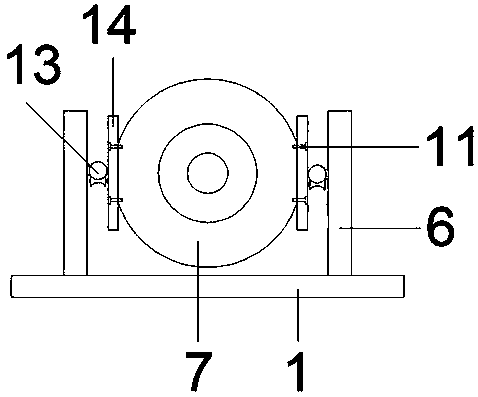

[0015] A blasting drilling machine, comprising a car body 1, a push handle 2, a frame 3, a damping spring 4, wheels 5, a limit plate 6, a slide rail 15, a motor 7, a drill bit 8, a hydraulic rod 9, and a controller 10, The wheels 5 and damping springs 4 are mounted on the bottom of the vehicle frame 3 using screws, and the vehicle frame 3 is welded to the bottom of the vehicle body 1, the push handle 2 is welded to the right side of the vehicle body 1, and the limit plate 6 is welded to the vehicle body 1. The upper surface of the body 1, and the inner side of the right end of the limiting plate 6 is equipped with a hydraulic rod 9, the motor 7 is installed on the inner side of the limiting plate 6 on both sides, and the motor 7 is connected with the hydraulic rod 9, and the drill bit 8 is connected with the motor 7, Described controller 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com