An automatic coconut green processing machine

A processing machine and green coconut technology, which is applied in the field of automatic green coconut processing machines, can solve the problems of operators' physical and mental damage, large manpower, danger, etc., and achieve the effects of reducing personnel injury accidents, expanding production scale, and reducing injury accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

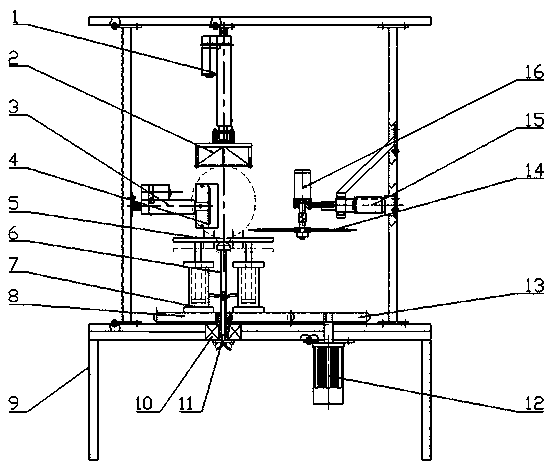

[0011] A frame 9 is provided with a tray drive motor 12 on the frame 9. A pinion 13 is provided on the tray drive motor 12. The pinion 13 meshes with the bull gear 8. The tray lift cylinder 7 is provided on the bull gear 8 to lift the tray. The cylinder 7 is provided with a tray 5, the tray 5 is provided with nail teeth, the center of the large gear 8 is also provided with a push rod 6, and the cone cutter 2 is arranged directly above the tray 5, and the cone cutter 2 and the cone cutter are electrically connected. The push rod 1 is connected, the left side of the tray 5 is provided with a side cutter 4, the side cutter 4 is connected with the side cutter electric push rod 3, the right side of the tray 5 is provided with a bottom-cutting circular saw blade 14, and the bottom-cutting circular saw blade 14 is contained on the bottom-cut circular saw blade drive motor 16, and the bottom-cut circular saw blade drive motor 16 links to each other with the bottom-cut electric push rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com