Processing method of bamboo shoot crisp chips with high quality and low fat

A low-fat, high-quality technology, applied in the direction of fat-containing food ingredients, food preservation, food ingredients, etc., can solve the problems of high fat content, reduce product oxidation degree, etc., to reduce oxidation degree, reduce fat content, reduce oxidation effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

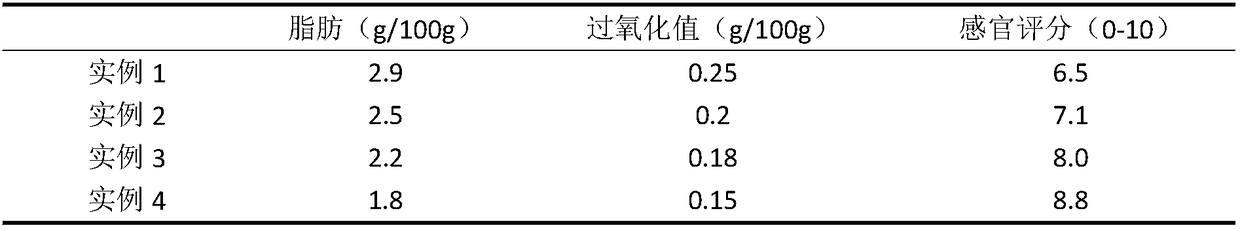

Examples

Embodiment 1

[0017] (1) Raw material pretreatment: remove the outer skin of fresh bamboo shoots, wash them with clean water, and cut them into 1.5cm slices;

[0018] (2) scalding and rinsing: after the bamboo shoot slices were rinsed 5 times with tap water, put into the NaCl solution with a mass percentage concentration of 5% and scald them for boiling. After the water boiled, continue to boil for 8 minutes, then pull out and rinse with clear water;

[0019] (3) Soaking: 1kg of bamboo shoots is put into 3L of 0.4% NaCl solution by mass percentage and soaked for 12h;

[0020] (4) Drain: Rinse the soaked bamboo shoots 4 times with tap water, remove and drain;

[0021] (5) Over-oiling: Pour 100ml of edible oil into the pot to preheat, put the drained bamboo shoots into the pot and stir-fry for 1 minute;

[0022] (6) Segmented frying: Put the oiled bamboo shoots into a 100°C air fryer and fry for 10 minutes, and the frying environment is air; pick up the bamboo shoots and immediately put them...

Embodiment 2

[0025] (1) Raw material pretreatment: remove the outer skin of fresh bamboo shoots, wash them with clean water, and cut them into 1.5cm slices;

[0026] (2) scalding and rinsing: after the bamboo shoot slices were rinsed 5 times with tap water, put into the NaCl solution with a mass percentage concentration of 5% and scald them for boiling. After the water boiled, continue to boil for 8 minutes, then pull out and rinse with clear water;

[0027] (3) Soaking: 1kg of bamboo shoots is put into 3L of 0.4% NaCl solution by mass percentage and soaked for 12h;

[0028] (4) Drain: Rinse the soaked bamboo shoots 4 times with tap water, remove and drain;

[0029] (5) Over-oiling: Pour 100ml of edible oil into the pot to preheat, put the drained bamboo shoots into the pot and stir-fry for 1 minute;

[0030] (6) Segmented frying: Put the oiled bamboo shoots into a 100°C air fryer and fry for 10 minutes, and the frying environment is air; pick up the bamboo shoots and immediately put them...

Embodiment 3

[0033] (1) Raw material pretreatment: remove the outer skin of fresh bamboo shoots, wash them with clean water, and cut them into 1.5cm slices;

[0034] (2) scalding and rinsing: after the bamboo shoot slices were rinsed 5 times with tap water, put into the NaCl solution with a mass percentage concentration of 5% and scald them for boiling. After the water boiled, continue to boil for 8 minutes, then pull out and rinse with clear water;

[0035] (3) Soaking: 1kg of bamboo shoots is put into 3L of 0.4% NaCl solution by mass percentage and soaked for 12h;

[0036] (4) Drain: Rinse the soaked bamboo shoots 4 times with tap water, remove and drain;

[0037] (5) Over-oiling: Pour 100ml of edible oil into the pot to preheat, put the drained bamboo shoots into the pot and stir-fry for 1 minute;

[0038] (6) Segmented frying: Put the oiled bamboo shoots into a 100°C air fryer and fry for 10 minutes, and the frying environment is air; pick up the bamboo shoots and immediately put them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com