Direct torque control strategy of five-bridge-arm inverter driving type dual-three-phase motor system

A direct torque control, inverter technology, applied in motor generator control, AC motor control, electronic commutation motor control, etc., to ensure normal operation, improve fault-tolerant control capabilities, and achieve easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0046] The direct torque control strategy of the dual three-phase motor system driven by the five-arm inverter of the present invention is specifically implemented according to the following steps:

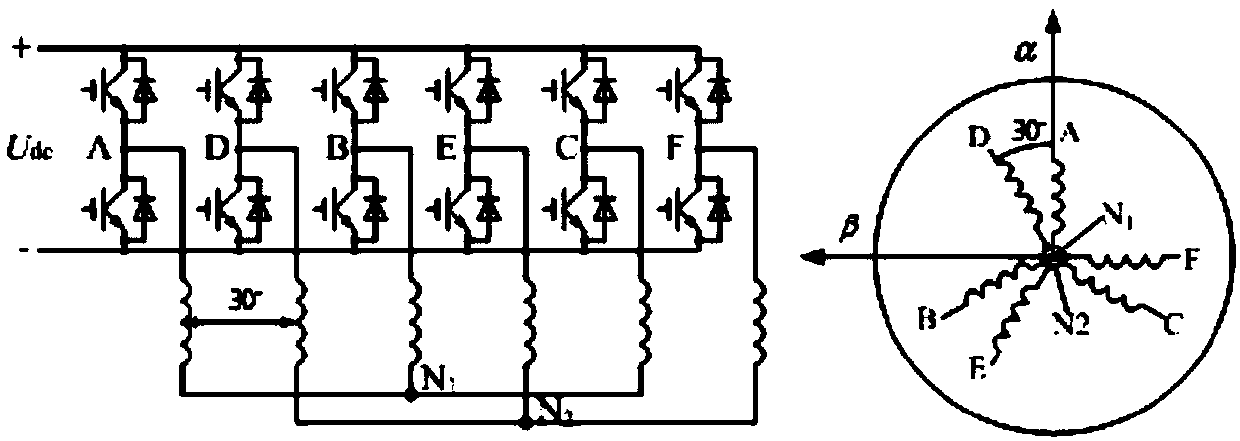

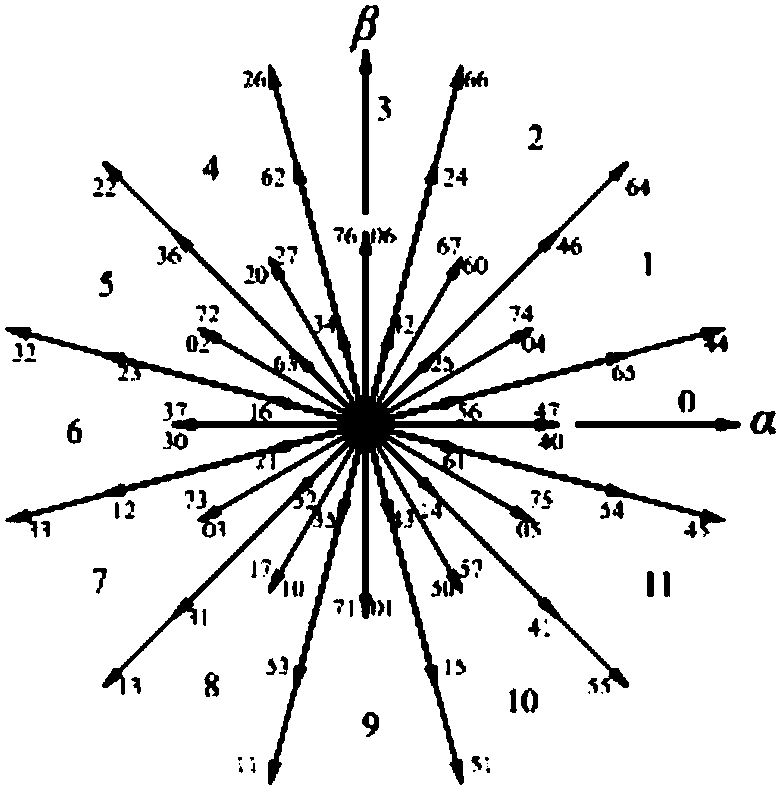

[0047] step 1, figure 1 It is the topological structure diagram of the dual three-phase motor system driven by the six-leg inverter. The basic principle of the direct torque control of the dual three-phase permanent magnet synchronous motor and the three-phase permanent magnet synchronous motor is the same, and the stator flux linkage ψ s Under the condition that the magnitude of the voltage remains constant, the torque angle δ is changed by selecting an appropriate voltage vector to obtain a fast torque response. Compared with the traditional three-phase motor, the six-phase inverter system has 64 basic voltage vectors, which provides more choi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com