Biological fermentation process control device

A technology for biological fermentation and process control, applied in the field of monitoring and display, control of related parameters, and biological fermentation process control devices, can solve problems such as complex efficiency, and achieve the effect of overcoming complexity and low efficiency and improving heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

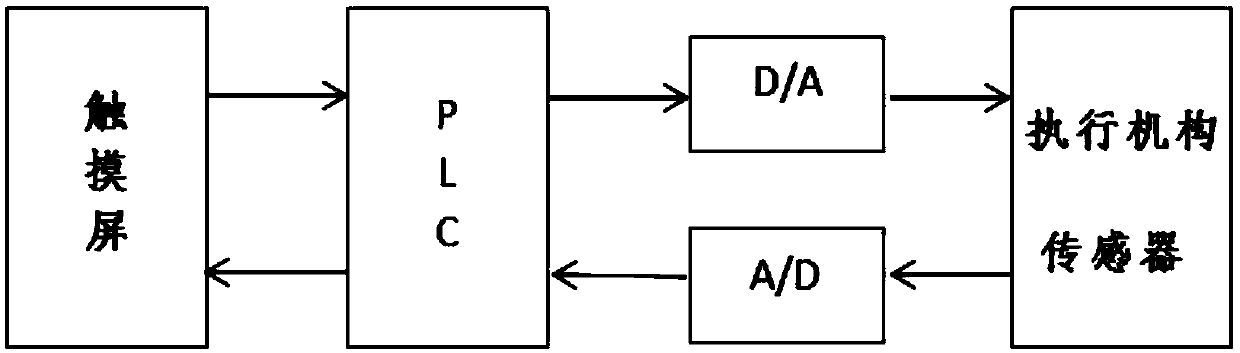

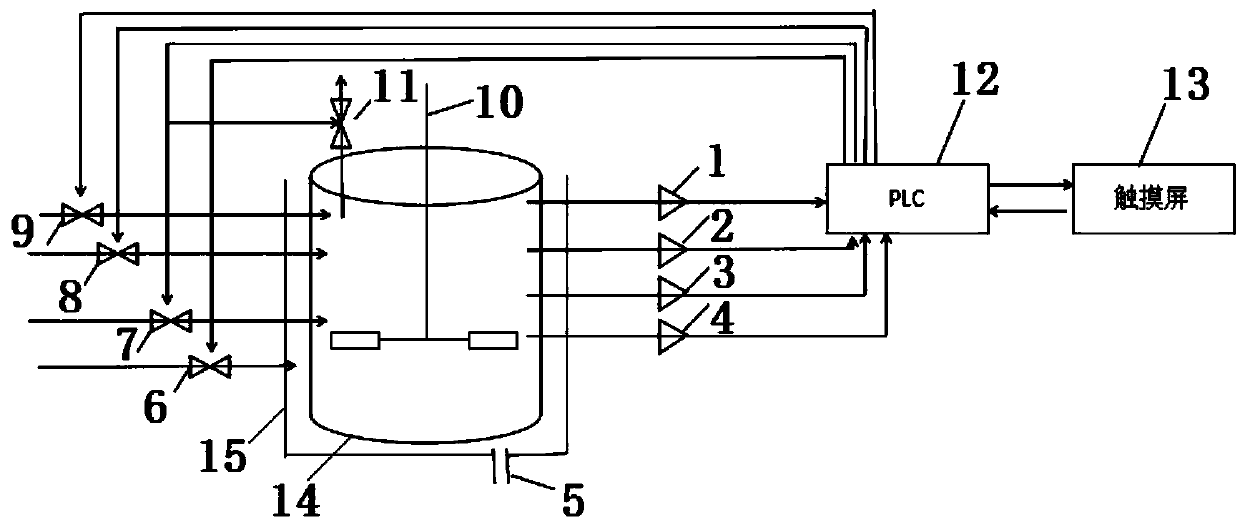

[0054] Embodiment 1: as Figure 1-2 As shown, a biological fermentation process control device includes a touch screen 13, a PLC controller 12, an A / D conversion module, a D / A conversion module, a sensor and an actuator;

[0055] The sensor is connected to the A / D conversion module, the A / D conversion module is connected to the PLC controller 12, the PLC controller 12 is connected to the touch screen 13, and the PLC controller 12 is connected to the D / A conversion module for controlling the execution structure work, The actuator is used to adjust the fermentation time, pressure, oxygen concentration and pH parameters;

[0056] The sensor is used to detect the analog signals of temperature, pressure, oxygen concentration, and pH parameters during fermentation. These analog signals are converted into digital signals by the A / D conversion module and then sent to the PLC controller 12 to match the set value. In comparison, the control signal after the control algorithm of the PLC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com