Online adjusting system for jet distribution of pulverized coal

A pulverized coal distribution and adjustment system technology, which is applied in the direction of block/powder supply/distribution, fuel supply regulation, combustion control, etc., can solve the problem of large pulverized coal distribution room and the inability to provide sufficient installation at the exit of the boiler pulverizer Space and other issues, to achieve the effect of system maintenance, high uniformity of pulverized coal distribution, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

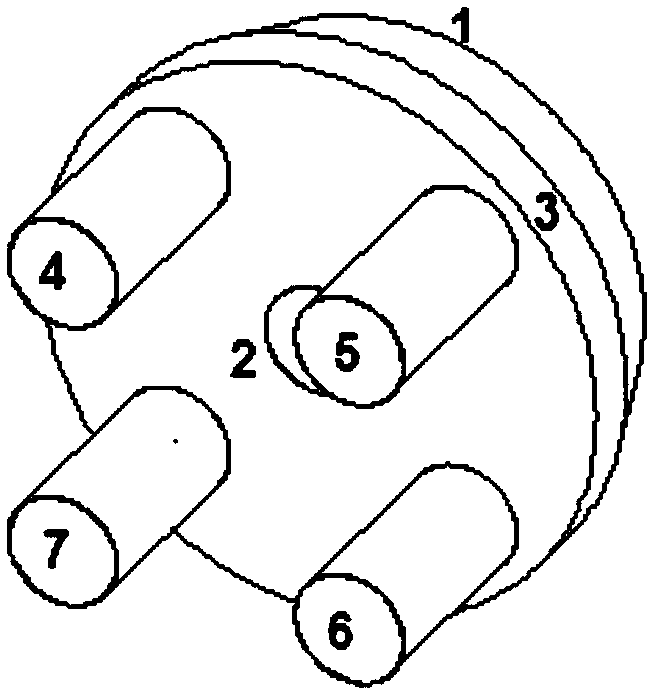

[0031] figure 1 Shows a three-dimensional view of the structure of the pulverized coal distributor according to the embodiment of the present invention, which consists of a distributor inlet 1 (that is, the outlet of the coal mill separator), a powder falling pipe 2, a pulverized coal distribution chamber 3, and branch pipes 4~ 7 components, fully connected inside the distributor. figure 2 yes figure 1 Corresponding main view.

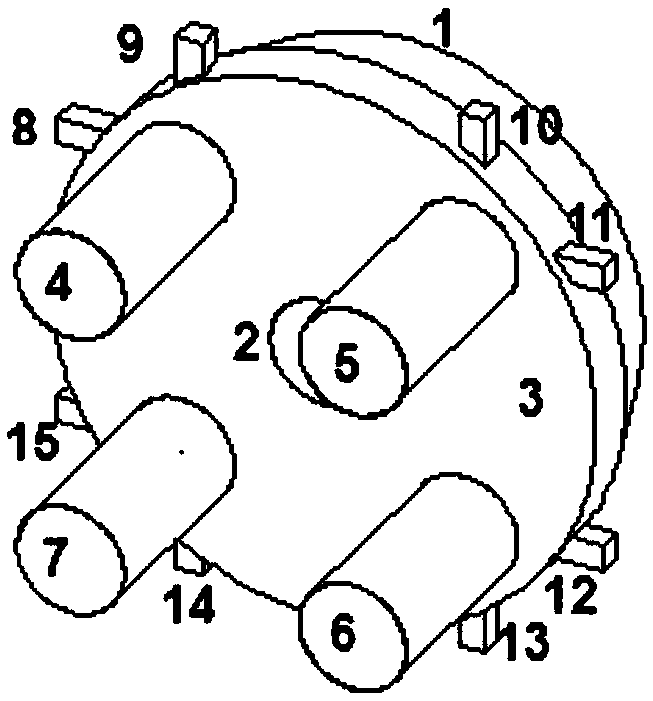

[0032] image 3 is the schematic diagram of the pulverized coal distributor and the jet nozzle, which is in figure 1 Add jet nozzles 8 to 15 on the basis of , and the nozzles 8 to 15 are arranged symmetrically about the central axis of the powder falling pipe 2 in the center of the distributor. The axis centers of the nozzles 8 to 15 pass through the centers of the adjacent branch pipes 4 to 7 respectively. ) is taken as 1 / 4 of the diameter of the branch pipe. Figure 4 The plane layout of eight jet nozzles is shown, and the directions of the je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com