Single-return-stroke WNS-structure boiler

A technology for boilers and furnaces, applied in the field of single-pass WNS structure boilers, which can solve problems such as easy flue gas leakage from high-temperature moving parts, increased pollutant NOx emissions, and high flame center temperature, so as to improve ignition conditions, reduce NOx production, The effect of reducing the temperature of the combustion flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

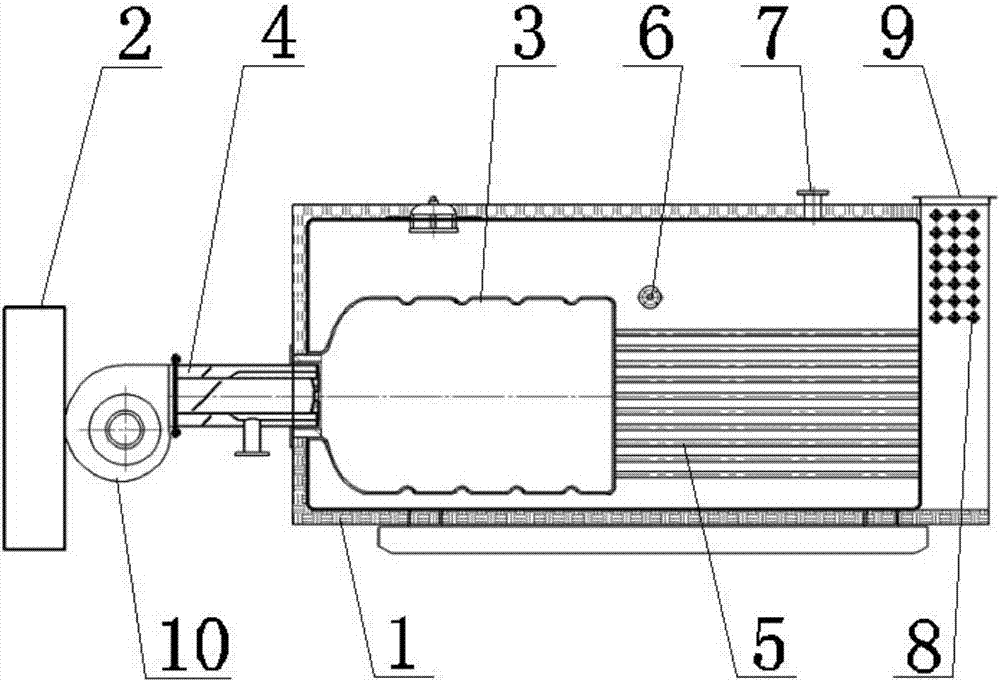

[0031] Such as figure 1 As shown, Embodiment 1 of the present invention provides a single return WNS structure boiler, including: control cabinet 2, burner 4, pot shell 1, corrugated furnace 3, smoke pipe group 5, water inlet 6, hot water or steam outlet 7. The economizer 8 and the flue gas outlet 9, wherein the water inlet 6, the hot water or steam outlet 7 and the flue gas outlet 9 are arranged on the surface of the pot shell 1. The control cabinet 2 controls the operation of the entire boiler, and the boiler can be arranged vertically or horizontally. The burner 4, the corrugated furnace 3 and the smoke pipe group 5 are sequentially connected; among them, the burner 4, the corrugated furnace 3 and the smoke pipe group 5 are connected coaxially in sequence; the burner 4 can be a single-stage fire burner or a double-stage fire burner. Burners, proportional burners, etc., preferably swirl burners here.

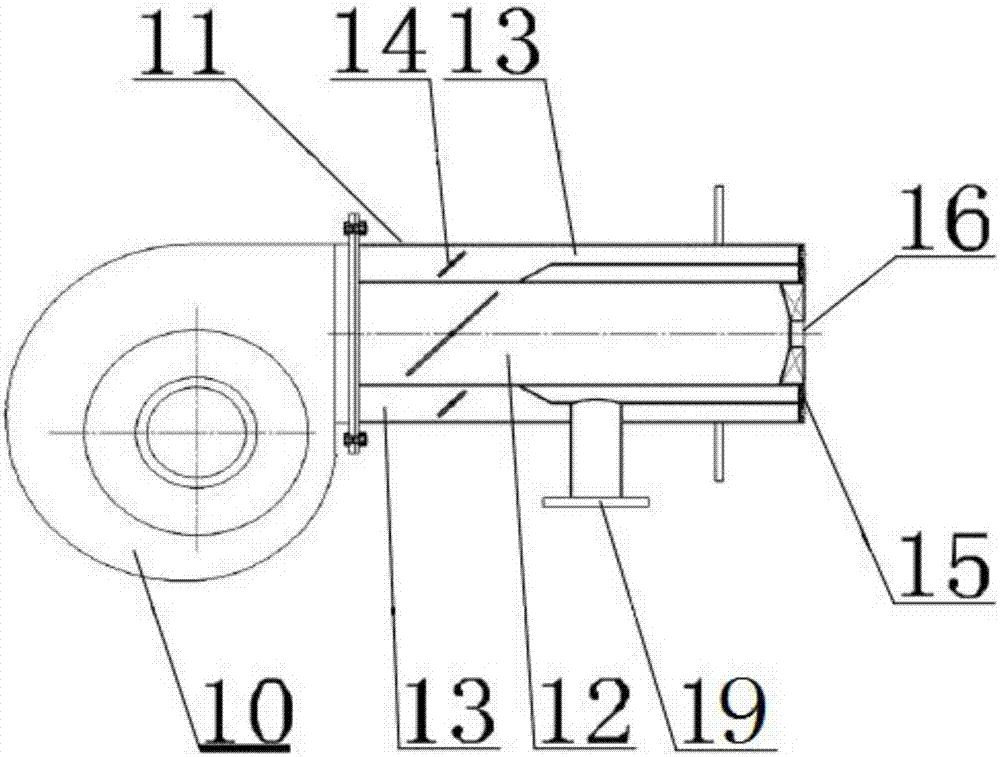

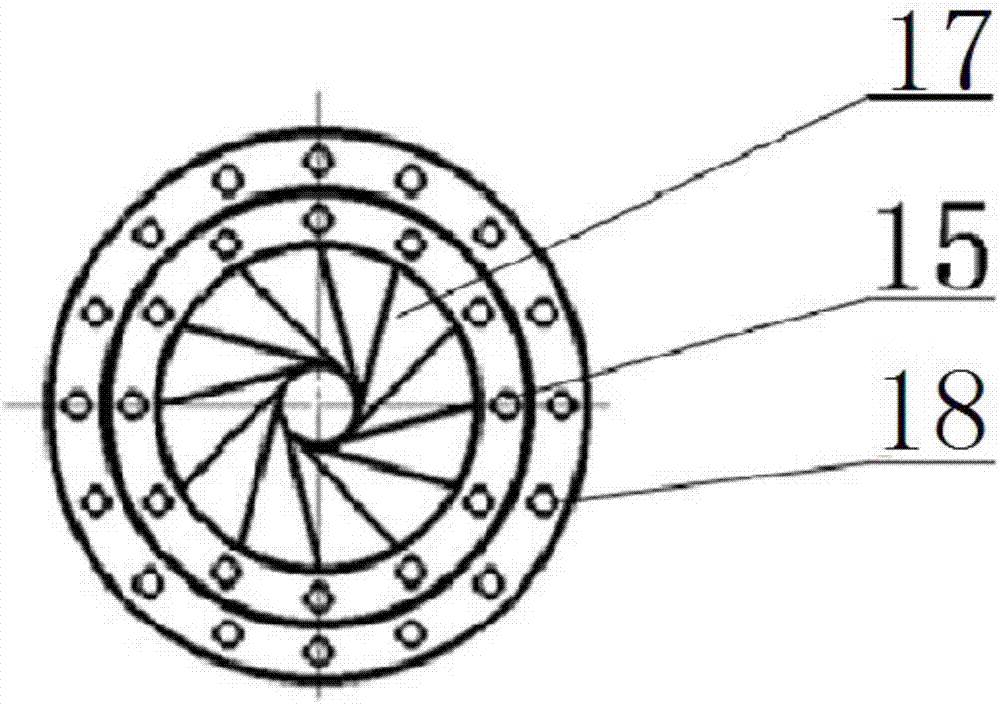

[0032] Such as Figure 2~3 Therefore, the burner 4 includes: a fan 10,...

Embodiment 2

[0040] On the basis of Embodiment 1, based on the above-mentioned structure, a water-cooled burner 23 is arranged around the burner 16, which is used to maintain a certain high temperature, radiate heat, and promote ignition; The rapid rise can reduce the temperature at the burner and protect the 3 walls and the front wall of the corrugated furnace from being damaged by high temperature. But when carrying out the low calorific value fuel combustion of utilization rate lower, the cooling function of water-cooled burner 23 has caused its combustion to hinder, for above-mentioned situation, as Figure 6 As shown, a refractory concrete covering layer 24 can be provided on the water-cooled burner 23 . When the combustion gas burns at the burner 16, under the protection of the refractory concrete covering layer 24, the high temperature at the burner 16 is maintained to radiate heat and promote fuel combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com