High hanging lamp for nuclear environment

A nuclear environment and shell technology, which is applied to the components of lighting devices, damage prevention measures for lighting devices, semiconductor devices of light-emitting elements, etc., can solve problems such as insufficient brightness, large power consumption, and large heat generation, and avoid Accumulation of dust, long-life use, and high sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the drawings and embodiments:

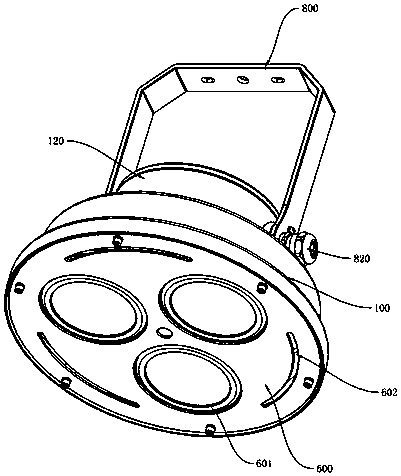

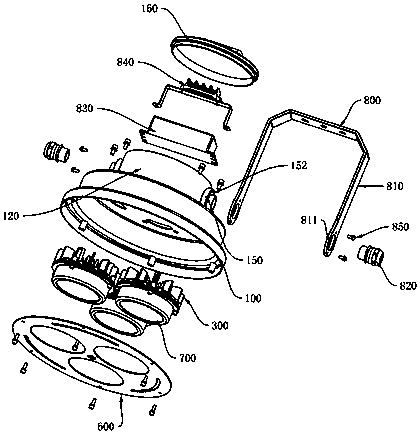

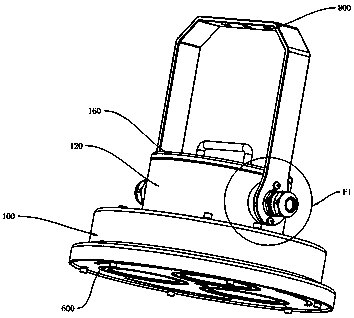

[0047] See Figure 1-Figure 15 , A high-hanging lamp for a nuclear environment, comprising, a housing 100, a fixing post 110 is arranged inside the housing 100 and a mounting shell part 120 is arranged on the top of the housing, the mounting shell part 120 and the housing end 140 Are connected to each other through the shell connecting part 130;

[0048] After the screw passes through the gland 600, it is assembled and fixed with the fixing post 110 to fix the gland 600 on the housing 100. The gland 600 is provided with a first through slot 601, and the first through slot 601 and the light source assembly The bottom of 700 is installed and fixed, and there is a gap between the light source assembly 700 and the inner wall of the first through groove 601;

[0049] The light source assembly 700 includes a heat sink 300 and a light-emitting board 430. The light-emitting board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com