Hydrogen sealing device and sealing method of steam turbine generator set

A steam turbine generator set, hydrogen sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of inability to realize the follow-up of pads and journals, unstable vibration, and generator insulation decline, etc. Improve unstable vibration phenomenon, reduce jamming phenomenon, small leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

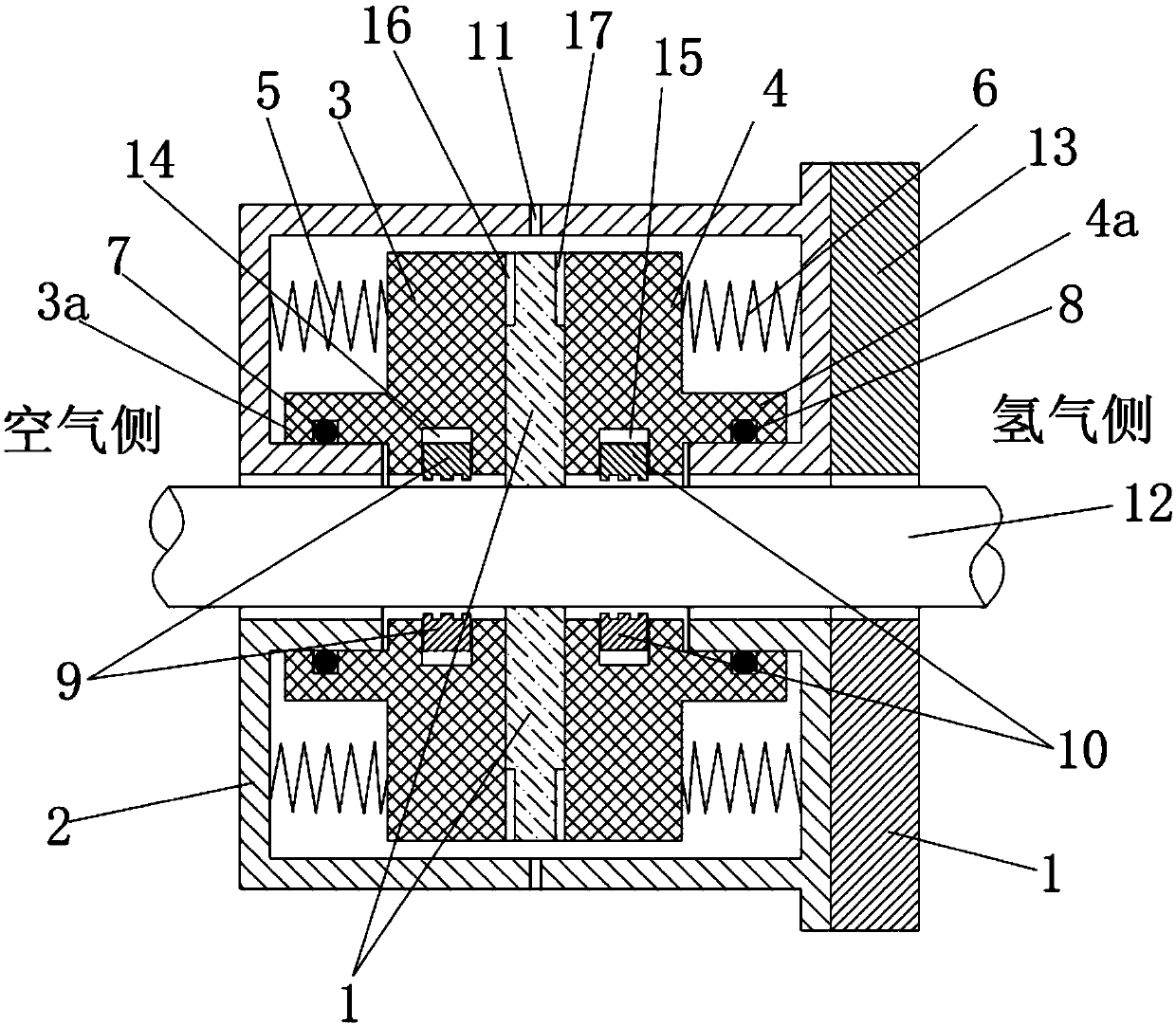

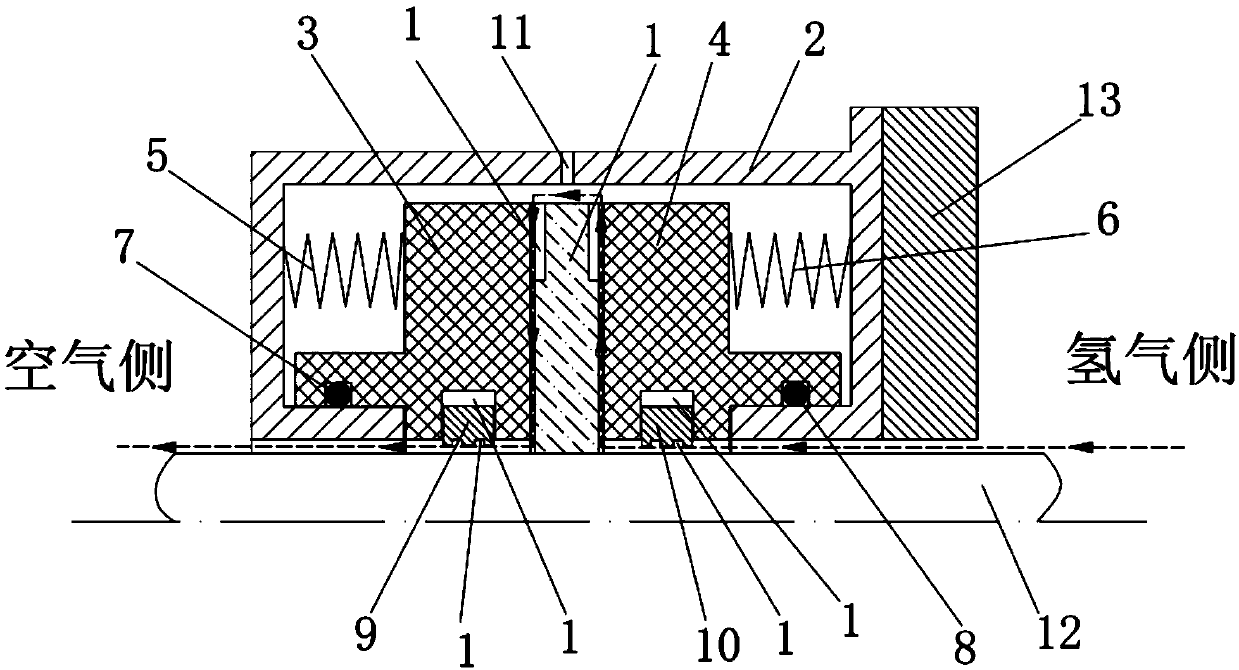

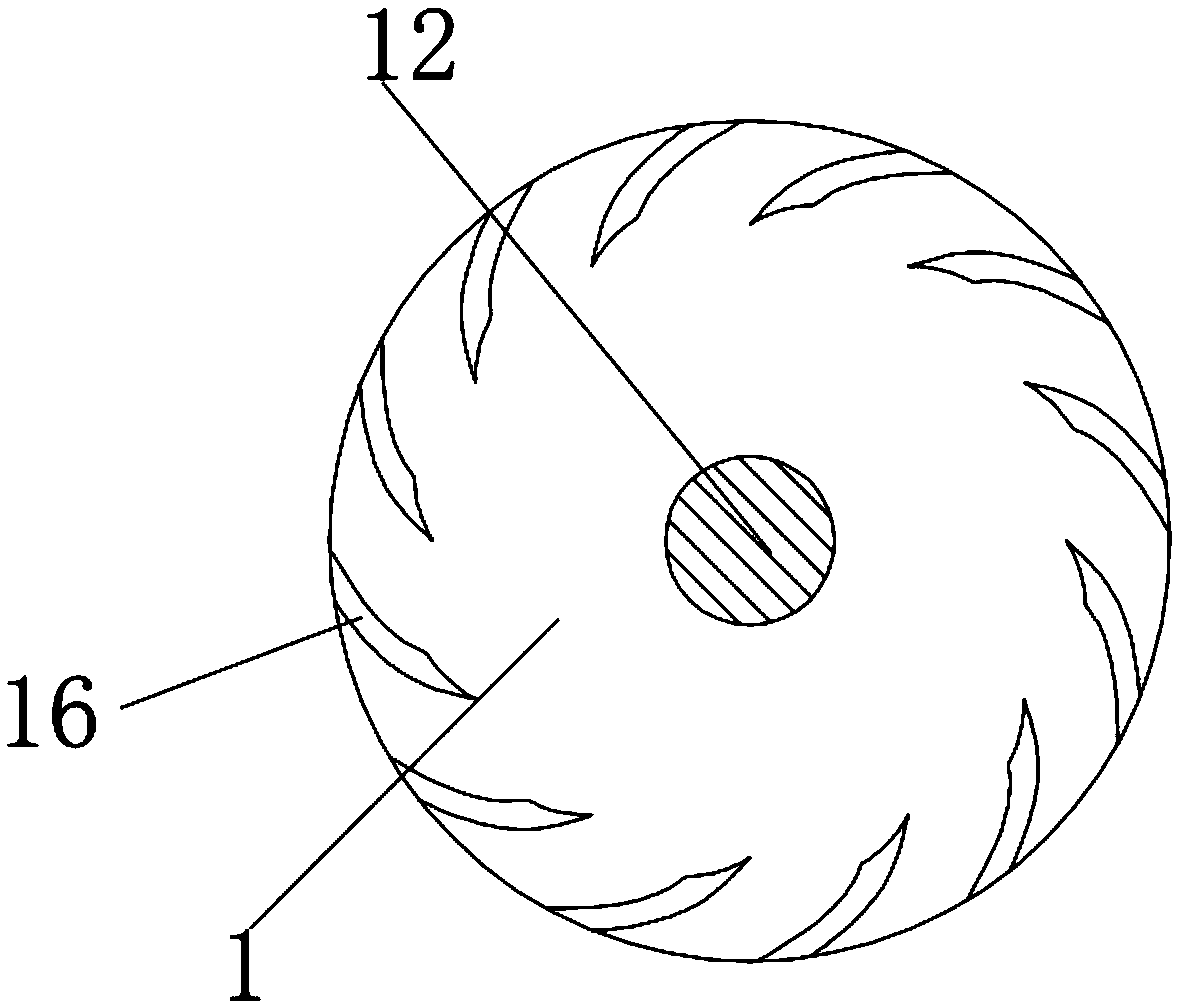

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Depend on Figure 1-6 Given, a hydrogen sealing device for a turbogenerator set in the present invention includes a generator shaft 12 and a generator end cover 13 arranged outside the generator shaft, the generator end cover 13 is a stationary part, and the generator shaft 12 is a rotating part , the generator shaft 12 passes through the generator end cover 13 and can rotate around its axis. There is a certain gap between the two to ensure that the generator shaft 12 does not contact the generator end cover 13 when rotating. The outer side of the generator shaft 12 A seal seat 2 fixed with the generator end cover 13 is provided. The seal seat 2 is a hollow structure with an opening facing the inner side of the generator shaft. The generator shaft 12 at the opening of the seal seat 2 is covered with a Together wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com