Multi-degree-of-freedom active vibration isolation device and method

A technology of active vibration isolation and degree of freedom, applied in the direction of shock absorbers, gas shock absorbers, spring/shock absorber design features, etc., can solve problems such as large electromagnetic interference, large volume and weight, and oil pollution, and achieve No electromagnetic interference, low natural frequency, and the effect of suppressing the resonance peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

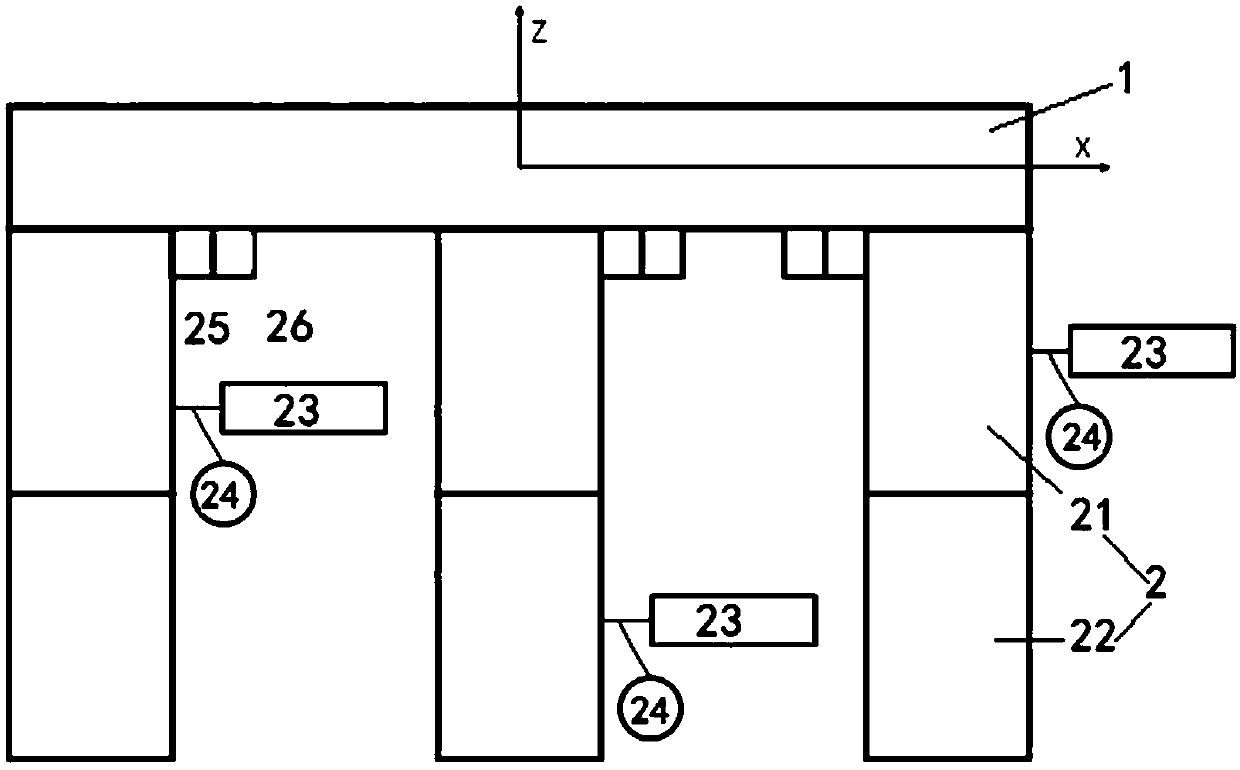

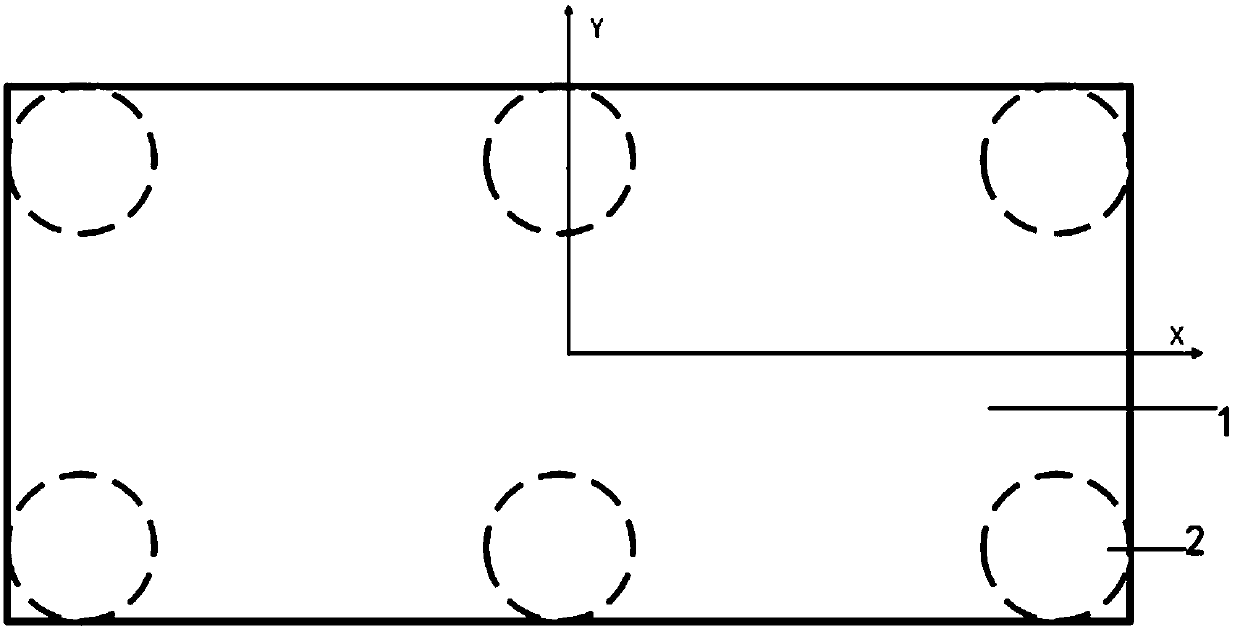

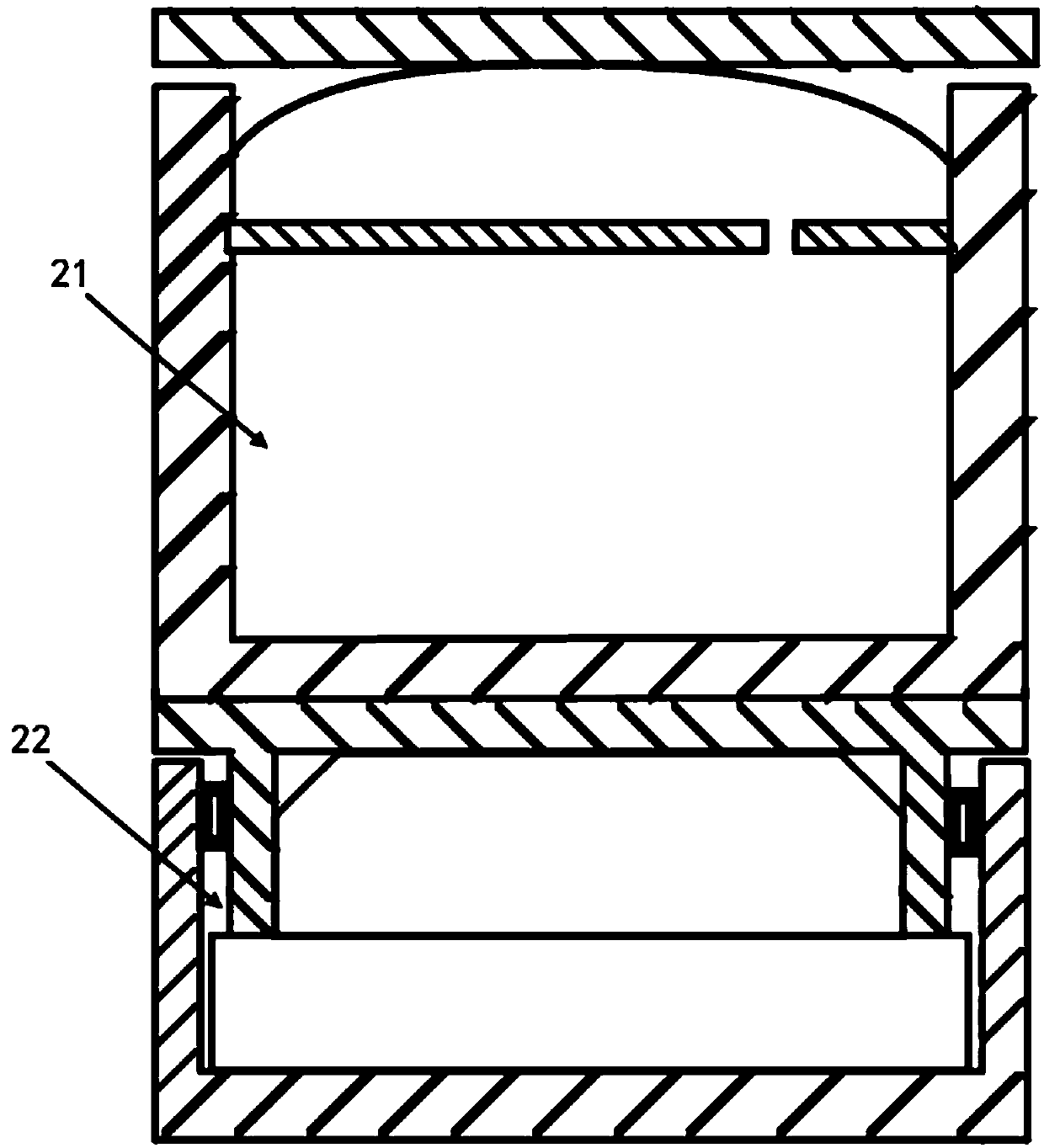

[0034] Such as figure 1 , figure 2 The illustrated embodiment is a multi-degree-of-freedom active vibration isolation device, including a platform 1 and six support legs 2 arranged on the lower edge of the support platform; the six support legs are evenly arranged in two rows, and each support leg has A pneumatic proportional valve 23, a pressure sensor 24 for detecting gas pressure, a displacement sensor 25 and a speed sensor 26 are provided, and the controller is electrically connected with each pneumatic proportional valve, each pressure sensor, each displacement sensor and each speed sensor, and each The pneumatic proportional valves are all in communication with the double-cavity vertical air springs and horizontal air springs of the corresponding support legs. Such as image 3 As shown, each support leg includes a double-cavity vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com