Installation method for urban utility tunnel pre-buried channel

A technology of integrated pipe gallery and installation method, applied in underwater structures, water conservancy projects, artificial islands, etc., can solve problems such as affecting the turnover times of formwork, damage to formwork, etc., so as to avoid unstable installation, ensure turnover times, and save construction. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

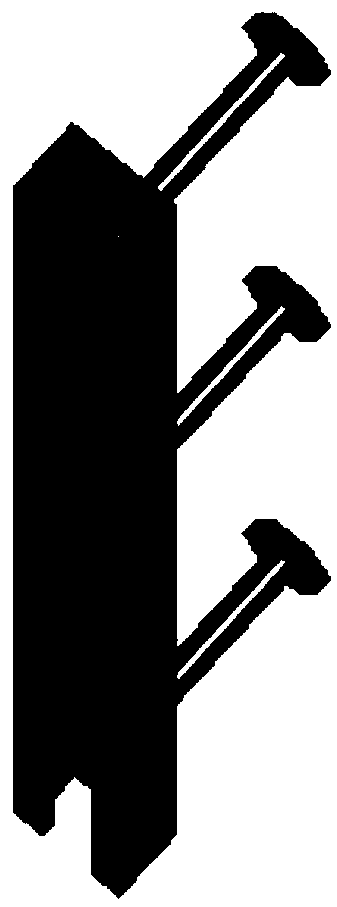

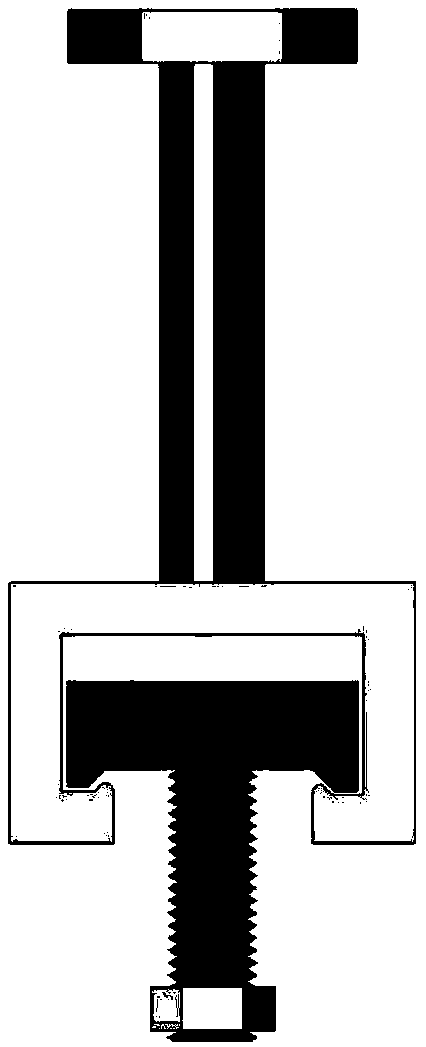

[0027] Such as Figure 1 to Figure 4 As shown, a method for installing the pre-buried groove of urban underground comprehensive utility gallery, the steps are as follows:

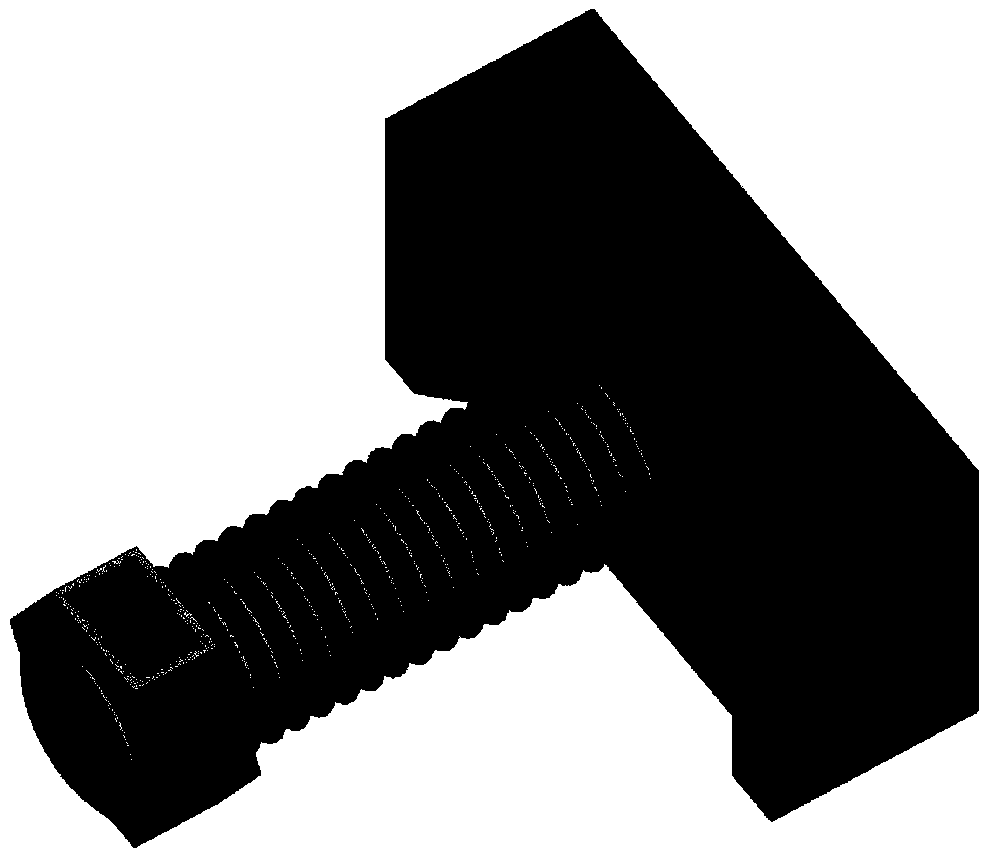

[0028] Step 1, making channel bolts

[0029] One end of the channel bolt has a nut, and the other end is set as a card according to the shape and size of the channel section of the embedded groove 4. The size of the card is slightly smaller than the channel size, which is convenient for installation and later removal. The channel bolt can be reused , saving costs.

[0030] Step 2, according to the screw size of the channel bolts and the position required by the design of the embedded groove 4, holes are pre-drilled on the formwork 2. Since the distance between the pre-embedded grooves 4 is uniform, the position of the holes on the formwork 2 is fixed, and the formwork 2 can continue to be used after the formwork is removed without re-drilling the holes to damage the formwork.

[0031] Step 3, install the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com