Bent cap of prefabricated assembled pier, pier, bridge and bridge assembling construction method

A technology for covering beams and bridge piers, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of high safety risk, concrete impact on construction progress, difficult quality control, etc., to achieve less interference, easy information management, broad Apply space effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

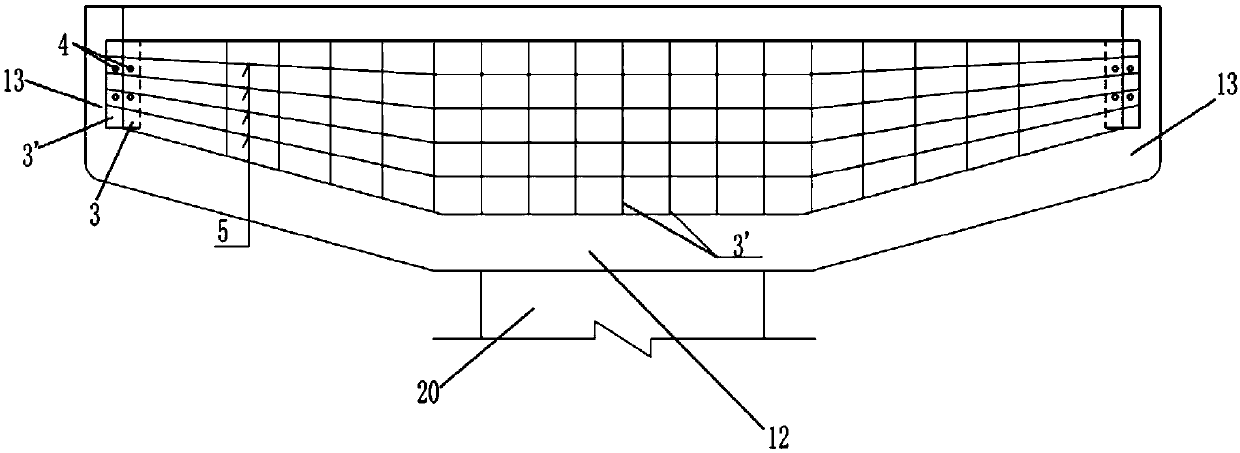

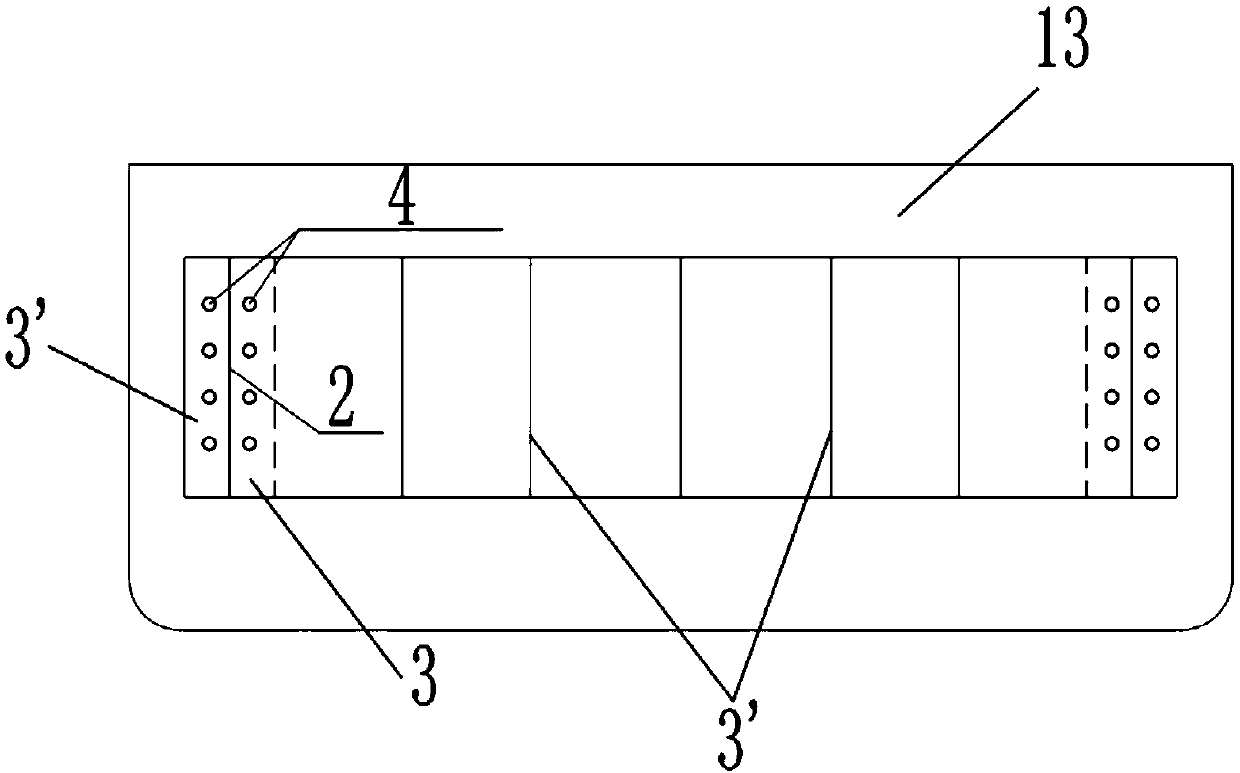

[0046] Such as Figure 1-4 As shown, the cap girder of the prefabricated bridge pier in the present invention includes: a prefabricated cap girder component 1, which has a contour section 12 and a variable height section 13 located at the side of the contour section 12, and the bottom is provided with a bridge pier body top The embedded opening 11, that is, the size of the opening 11 is larger than the size of the top of the pier body to accommodate the top of the pier body; the inner mold is arranged inside the prefabricated cap beam member 1, and is A closed structure around the inner wall of the prefabricated cover beam member 1.

[0047] Specifically, the prefabricated cover beam member 1 is a hollow shell structure without a cover made of reinforced concrete, and the thickness of the shell structure is 200-300 mm. In this embodiment, the thickness is preferably 200 mm. Therefore, the prefabricated cover beam member 1 of the shell structure can be lighter and more conveni...

Embodiment 2

[0058] This embodiment also provides a bridge pier structure, such as Figure 8 As shown, it includes the cover girder and the pier body 20 described in the first embodiment; the outer peripheral surface of the pier body 20 is provided with the lower end face of the cover girder and is used for temporary support during the construction process. The annular boss 21 of the prefabricated cover beam member 1, the shape of the annular boss 21 can be further optimized, so that it is not obtrusive and more beautiful after being combined with the cover beam; The main force rib 22, the pier body 20 pier top is embedded in the opening 11 of the prefabricated cover beam member, and one end of the main force rib 22 of the pier body extends into the interior of the prefabricated cover beam member 1; in this embodiment, The cross-section of the pier body 20 is a geometric figure such as a circle or a rectangle, and the main reinforcement 22 of the pier body is HRB400 steel bar or HRB500 ste...

Embodiment 3

[0060] This embodiment provides a bridge, such as Figure 8 As shown, it includes the bridge pier structure described in Embodiment 2, the pad stone provided on the upper end surface of the cover beam, the support 30 provided on the pad stone, and the track beam body installed on the support 30 And the fixing ribs arranged in the cross-bridge direction in the prefabricated cover beam member 1 .

[0061] Further, the support 30 is preferably a cast steel tensile support, and its lower part is connected with a support anchor bar 10 extending into the interior of the prefabricated cover beam member 1, which requires high precision, can effectively transmit loads, and has Certain deformation coordination ability meets the requirements of smooth driving, and at the same time facilitates later assembly installation and alignment adjustment;

[0062] Such as Figure 9 As shown, the pad stone includes: some first reinforcement ribs 40, some second reinforcement ribs 41 and a pad sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com