A kind of antibacterial antifouling shirt fabric

A technology for shirts and fabrics, applied in the field of shirt fabrics, can solve the problems of expensive silver fiber and single function, and achieve the effects of not easy to deform, good antibacterial properties, and good stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

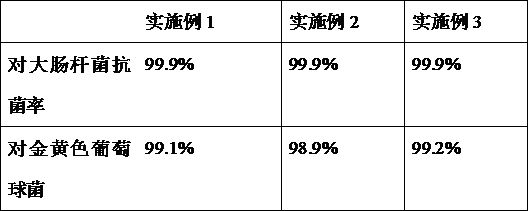

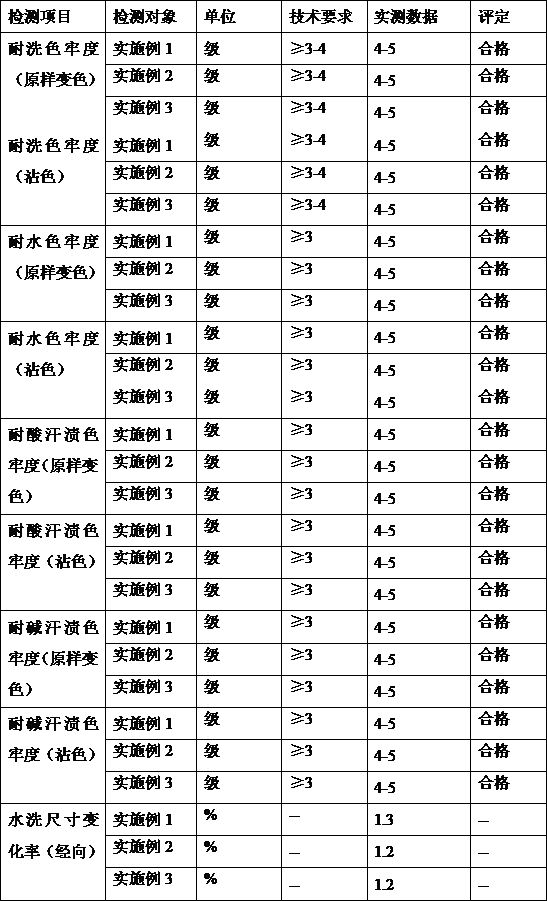

Examples

Embodiment 1

[0021] An antibacterial and antifouling shirt fabric, the warp yarn is boron phosphorus synergistic flame retardant viscose fiberX 1 , Weft yarn is hydrophilic anti-fouling and antibacterial polyester fiber Y 1 , warp density 512 / 10cm, weft density 340 / 10cm.

[0022] Wherein, the boron and phosphorus synergistic flame-retardant viscose fiber X 1 The preparation method, in parts by mass, comprises the steps:

[0023] Add 0.4 parts of trimethyl borate, 16 parts of α-cellulose, 11 parts of ethanol, and 74 parts into the reaction device, add sodium hydroxide to adjust the pH to 8, fully stir to dissolve, and then add 0.5 parts under heating to 43°C Parts of triethyl phosphoacetate were reacted for 2.5 hours, and the boron-phosphorus modified solution was obtained after cooling; the boron-phosphorus modified solution was subjected to vacuum degassing treatment at 39°C for 50 minutes to obtain the spinning solution; the spinning solution was squeezed into the 36°C Coagulate in a ...

Embodiment 2

[0029] An antibacterial and antifouling shirt fabric, the warp yarn is boron phosphorus synergistic flame retardant viscose fiberX 2 , Weft yarn is hydrophilic anti-fouling and antibacterial polyester fiber Y 2 , warp density 512 / 10cm, weft density 340 / 10cm.

[0030] Wherein, the boron and phosphorus synergistic flame-retardant viscose fiber X 2 The preparation method, in parts by mass, comprises the steps:

[0031] Add 0.2 parts of trimethyl borate, 15 parts of α-cellulose, 8 parts of ethanol, and 70 parts into the reaction device, add sodium hydroxide to adjust the pH to 8, fully stir to dissolve, and then add 0.3 parts under heating to 40°C Parts of triethyl phosphoacetate were reacted for 3 hours, and after cooling, the boron-phosphorus modified solution was obtained; the boron-phosphorous modified solution was subjected to vacuum degassing treatment at 35°C for 60 minutes to obtain the spinning solution; the spinning solution was squeezed into 30°C to solidify Coagulat...

Embodiment 3

[0037] An antibacterial and antifouling shirt fabric, the warp yarn is boron phosphorus synergistic flame retardant viscose fiberX 3 , Weft yarn is hydrophilic anti-fouling and antibacterial polyester fiber Y 3 , warp density 512 / 10cm, weft density 340 / 10cm.

[0038] Wherein, the boron and phosphorus synergistic flame-retardant viscose fiber X 3 The preparation method, in parts by mass, comprises the steps:

[0039] Add 0.5 parts of triethyl borate, 18 parts of α-cellulose, 15 parts of ethanol, and 80 parts into the reaction device, add sodium hydroxide to adjust the pH to 8, fully stir and dissolve, and then add 0.6 parts under heating to 50°C Parts of triethyl phosphoacetate were reacted for 1 hour, and after cooling, the boron-phosphorus modified solution was obtained; the boron-phosphorous modified solution was subjected to vacuum degassing treatment at 40°C for 40 minutes to obtain the spinning solution; the spinning solution was squeezed into 40°C to solidify Coagulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com