Converter steelmaking endpoint carbon content and temperature control method

A temperature control method and a technology for end-point carbon content, which are applied in the field of iron and steel metallurgy, and can solve the problems of poor error or generality, low control model accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

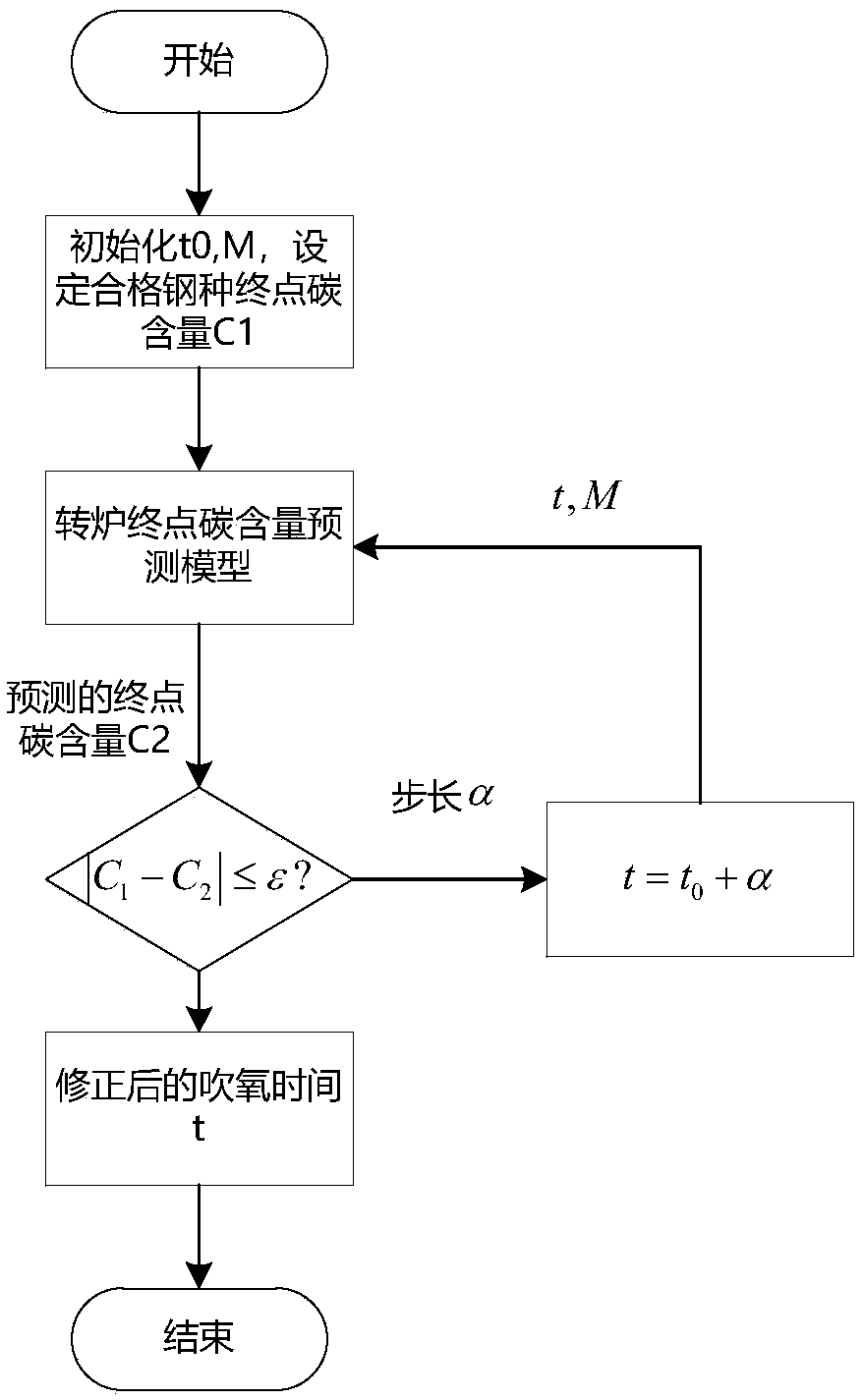

[0032]The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0033] figure 1 It is a schematic block diagram of a method for controlling carbon content and temperature at the end point of converter steelmaking according to a preferred embodiment of the present invention, as figure 1 As shown, on the one hand, the present invention provides a method for controlling carbon content and temperature at the end point of converter steelmaking, including: according to the characteristic parameters of the initial state of molten iron and the requirements of the smelting target steel grade, based on the carbon content and temperature control model at the end point of converter smelting , to control the carbon content and temperature at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com