Inspection method of endospores and heat-resisting endospores

An inspection method and spore technology, applied in the field of food analysis and detection, can solve the problems of insufficient comprehensive and effective inspection of spores and heat-resistant spores, and achieve the effects of reducing losses, ensuring thoroughness and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

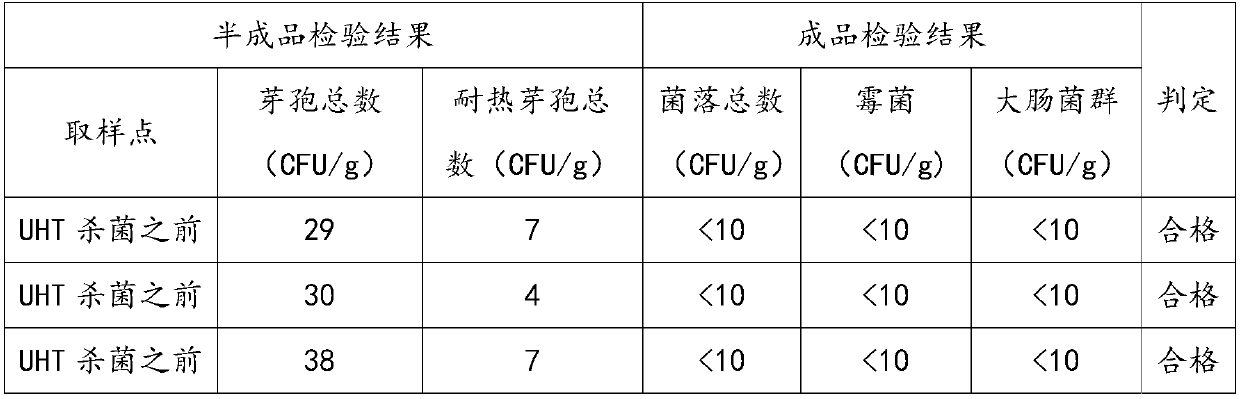

Embodiment 1

[0042] The present embodiment provides a kind of inspection method of spore and heat-resistant spore, comprises the following steps:

[0043] Assess the heat resistance of microorganisms: According to the characteristics of heat-resistant spores and heat-labile vegetative bodies in spore-containing microorganisms, the vegetative bodies in the samples to be tested are eliminated by heating, and spores are isolated.

[0044] Sampling: According to the production process of fresh cream semi-finished products, samples are taken before entering the UHT step. The first sample and the second sample are taken respectively. The first sample is the sample of the spore to be tested, and the second sample is the sample of the heat-resistant spore to be tested.

[0045] Among them, the production process of fresh cream semi-finished products includes: water phase deployment at 65-70°C; emulsification at 55-65°C, emulsification time is 0.5-1.5h; pre-homogenization; At 65°C, the maintenance ...

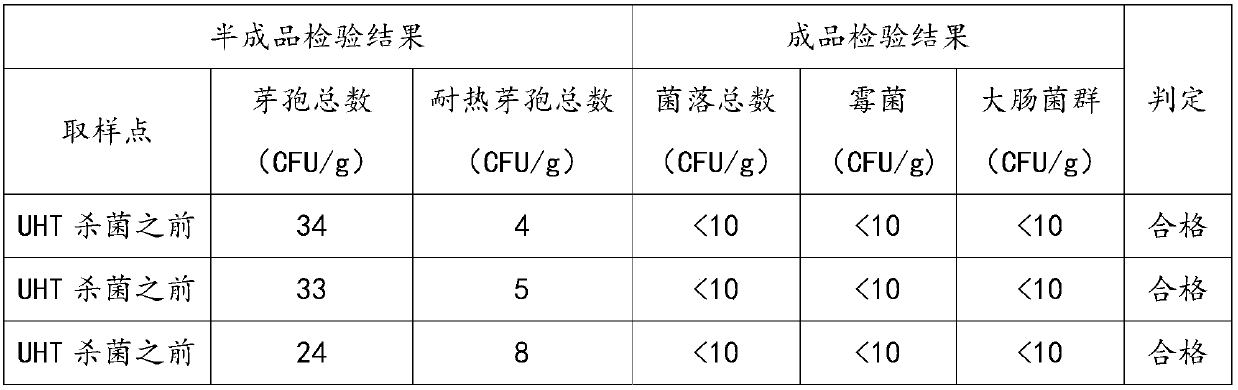

Embodiment 2

[0060] The present embodiment provides a kind of inspection method of spore and heat-resistant spore, comprises the following steps:

[0061] Assess the heat resistance of microorganisms: According to the characteristics of heat-resistant spores and heat-labile vegetative bodies in spore-containing microorganisms, the vegetative bodies in the samples to be tested are eliminated by heating, and spores are isolated.

[0062] Sampling: Sampling according to the semi-finished product production process of fresh cream before entering the UHT step, taking the first sample and the second sample respectively, the first sample is the sample of the spore to be tested, and the second sample is the heat-resistant spore to be tested sample.

[0063] Among them, the production process of fresh cream semi-finished products includes: water phase deployment at 65-70°C; emulsification at 55-65°C, emulsification time is 0.5-1.5h; pre-homogenization; At 65°C, the maintenance time is 0.3~0.8h; UHT ...

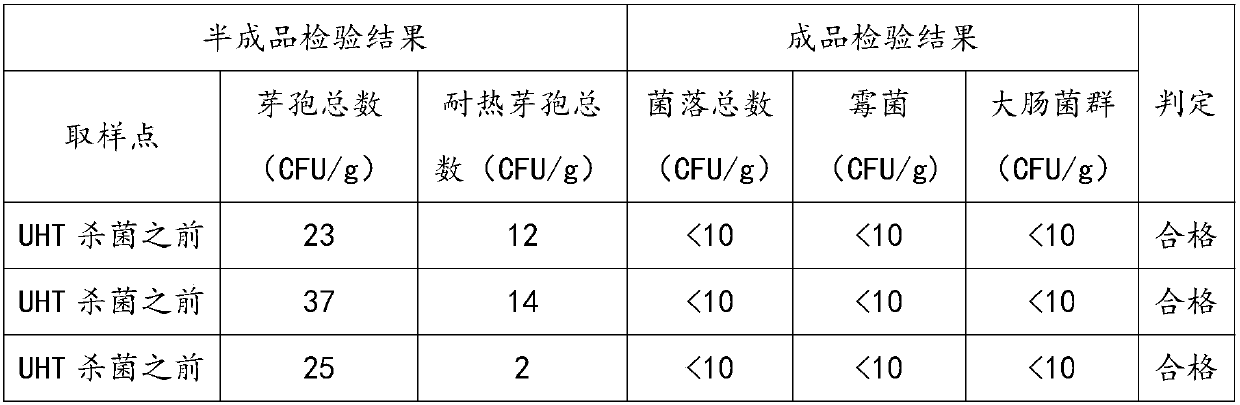

Embodiment 3

[0075] The present embodiment provides a kind of inspection method of spore and heat-resistant spore, comprises the following steps:

[0076] Assess the heat resistance of microorganisms: According to the characteristics of heat-resistant spores and heat-labile vegetative bodies in spore-containing microorganisms, the vegetative bodies in the samples to be tested are eliminated by heating, and spores are isolated.

[0077] Sampling: Sampling according to the semi-finished product production process of fresh cream before entering the UHT step, taking the first sample and the second sample respectively, the first sample is the sample of the spore to be tested, and the second sample is the heat-resistant spore to be tested sample.

[0078] Among them, the production process of fresh cream semi-finished products includes: water phase deployment at 65-70°C; emulsification at 55-65°C, emulsification time is 0.5-1.5h; pre-homogenization; At 65°C, the maintenance time is 0.3~0.8h; UH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com