a no 3 - Method for reducing hexavalent chromium in methane matrix biofilm

A technology of biofilm and hexavalent chromium, applied in the field of biological reduction of complex pollutants, can solve problems such as human health hazards, carcinogenicity, and teratogenicity

Active Publication Date: 2020-07-14

ZHEJIANG UNIV

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cr(VI) is carcinogenic, teratogenic and mutagenic to organisms, and has great health risks to the human body

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0037] (1) Preparation of simulated wastewater

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

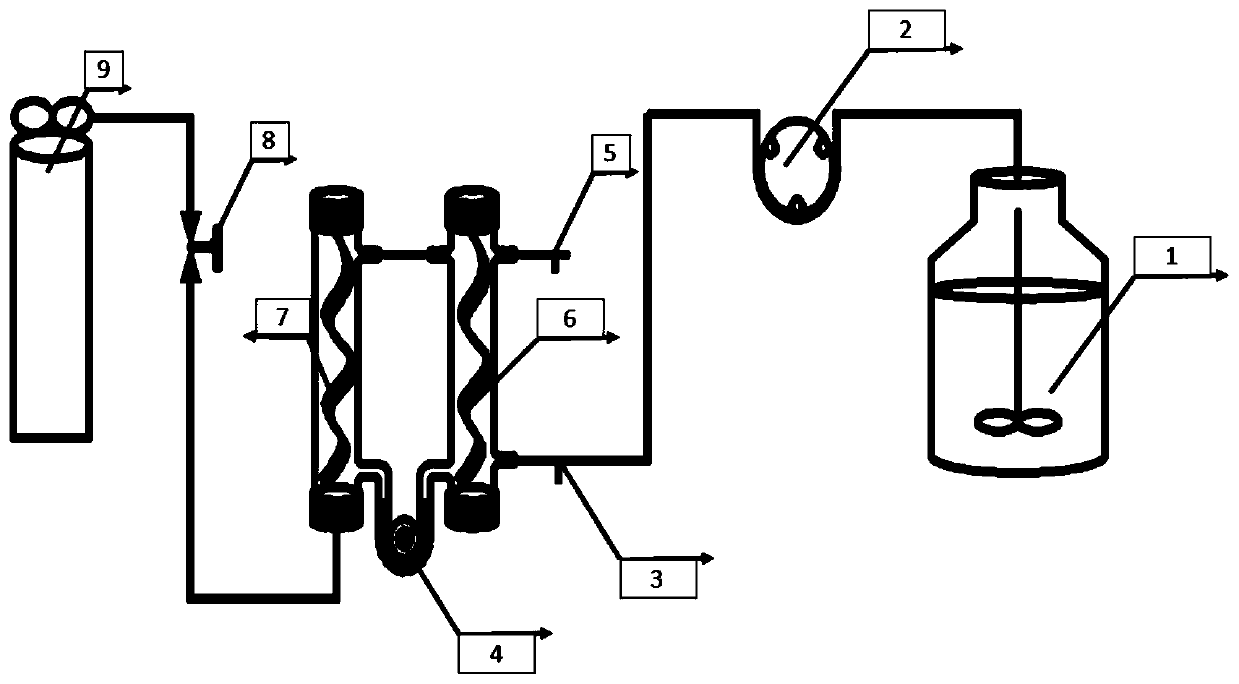

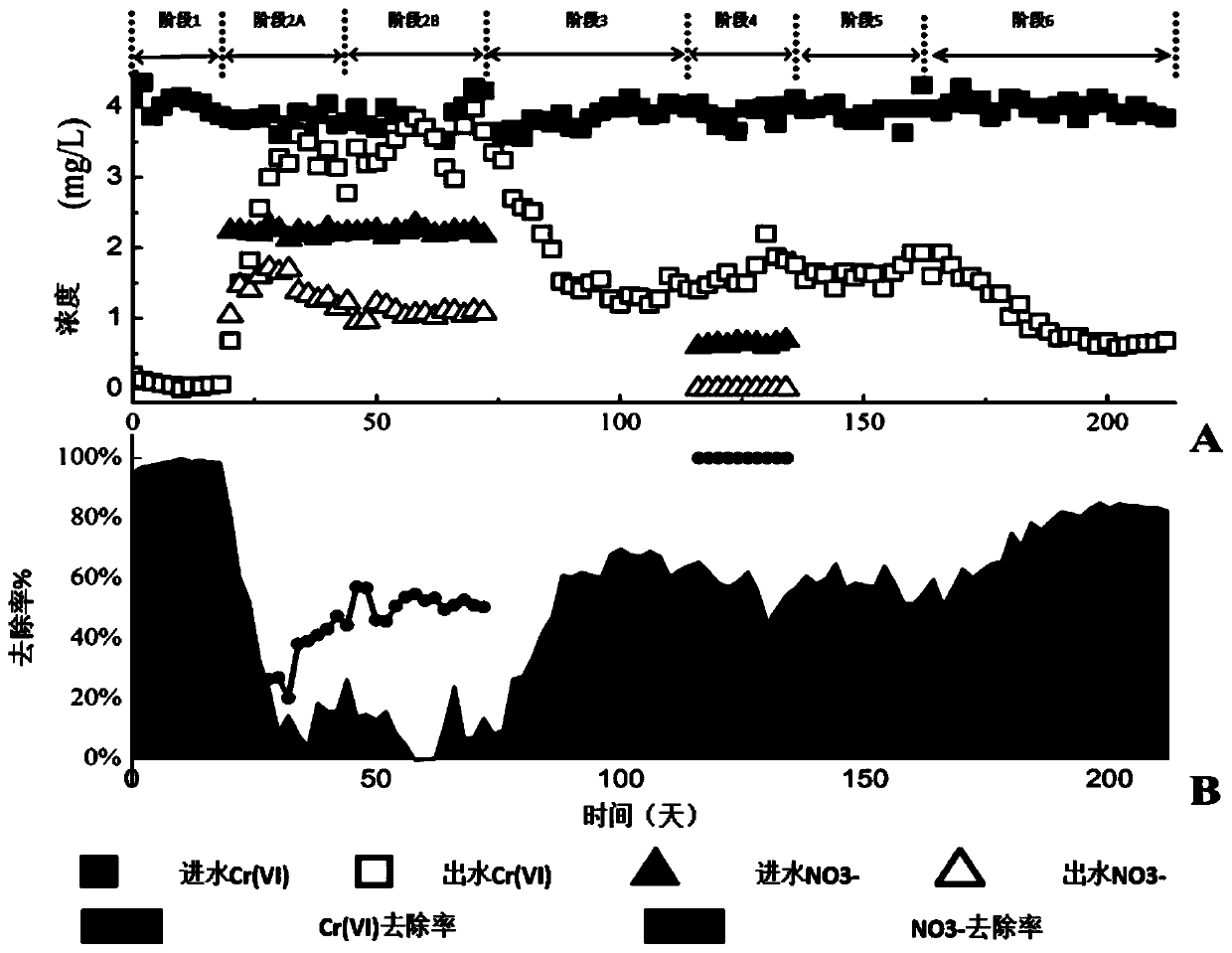

The invention relates to a biological reduction technology for composite pollutants, and aims to provide a method for reducing hexavalent chromium in a methane matrix biomembrane by NO<3><->. The method includes the following steps: adding Na2CrO4 and NaNO3 to an inorganic medium, and allowing the obtained medium, for later use, to stand under a micro-aerobic condition; introducing simulated wastewater into a methane matrix membrane bioreactor, adding CrO<4><2-> and activated sludge, and carrying out self-circulation to obtain the a bacterial solution; introducing the simulated wastewater andCH4 into the reactor in a continuous flow manner, and controlling the concentration of NO<3><-> in inlet water in stages; and ensuring that the concentrations of the CrO<4><2-> and NO<3><-> in outletwater reach a steady state for at least 10 days in every running stage. Compared with the prior art, the method has the following advantages: the high load of NO<3><-> has a significant irreversible inhibition effect on the reduction of Cr(VI); the introduction of the NO<3><-> deceases Meiothermus originally involved in the reduction of Cr(VI) and makes alpha-proteobacteria enriched; and when theNO<3><-> is removed, beta-proteobacteria become important, so the beta-proteobacteria play a potential role in Cr(VI) reduction.

Description

technical field [0001] The invention belongs to the technical field of biological reduction of complex pollutants, in particular to a 3 - A method for the reduction of hexavalent chromium in methane matrix biofilms. Background technique [0002] Metal chromium (Cr) is an important alloying element and is widely used in industries (such as: petroleum refining, electroplating, dyes and wood preservation, etc.). These industries have produced a large amount of chromium-containing polluted wastewater, among which CrO 4 2- It is the main chromium-containing pollutant. Cr(VI) has carcinogenicity, teratogenicity and mutagenicity to organisms, and has great health risks to human body. The U.S. Environmental Protection Agency defines the maximum contamination limit (MCL) of chromium in drinking water as 100 μg-Cr / L. At the same time, nitrate (NO 3 - ) are widely used in agricultural fertilizers and industrial production, surface water and groundwater contaminated with chromiu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F3/28C02F3/34C02F101/22

CPCC02F1/70C02F3/006C02F3/2853C02F3/34C02F2101/22Y02E50/30

Inventor 赵和平钟亮吕盘龙王振石凌栋

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com