Carbonization repair method of volatile organic compound-heavy metal compound polluted soil

A technology for soil contaminated with volatile organic compounds and heavy metals, applied in the restoration of polluted soil, etc., can solve the problems of low restoration efficiency, high economic cost, secondary pollution, etc., and achieve high restoration efficiency, high continuous operation rate, and avoidance of escape. The effect of scatter and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

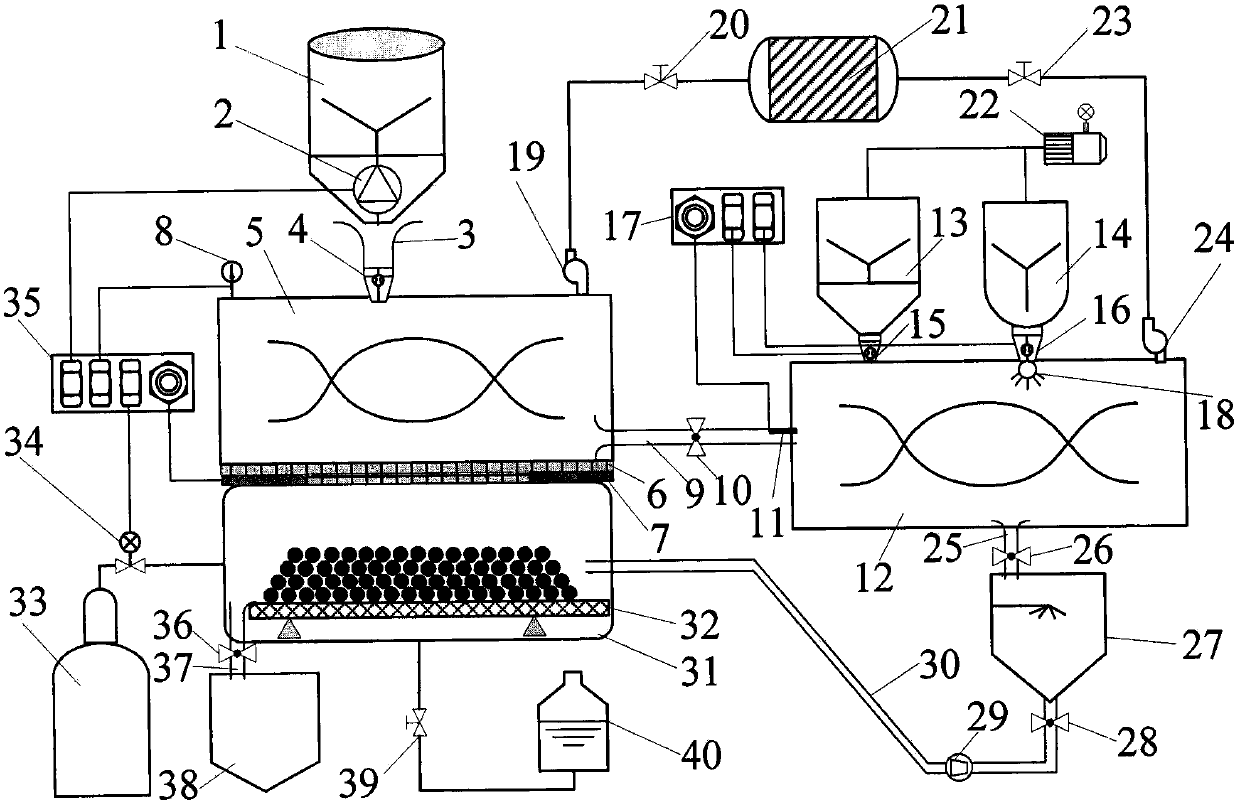

[0043] A carbonation restoration method for volatile organic compound-heavy metal composite polluted soil, characterized in that it comprises the following steps:

[0044] a. Pretreatment of composite polluted soil: in the pretreatment device 1, the plant roots, weeds, domestic garbage, solid waste, gravel and other debris in the volatile organic compound-heavy metal composite polluted soil to be treated are passed through mechanical raking nails or The vibrating screen removes the polluted soil and breaks the polluted soil into small particles of polluted soil through the built-in crushing device. The composition and concentration of heavy metals are monitored by the heavy metal pollution monitor in the pollution monitoring device 2;

[0045] b. Separation and extraction of organic pollutants: Open the feeding valve 4, the electric heating plate 7, the stirring device, the exhaust fan A19 and the second control valve 20 in turn, adjust the single feeding amount according to t...

Embodiment 2

[0057] On the basis of Example 1, when the organic pollutant in the composite polluted soil is gasoline, the gasoline concentration in the soil is 4g / kg, and the initial moisture content is about 20%, the minimum temperature when the electric heating plate is set to start is 40°C, That is, when the temperature is lower than 40 ℃, the electric heating plate is automatically activated, and the pumping time is 30 minutes, and the removal rate of organic pollutants is more than 95%. When the gasoline in the polluted soil is volatilized, the moisture content of the polluted soil is 5%-7%, the powder curing agent added to the heavy metal polluted soil is 0%, the slurry curing agent added is 25%, and the slurry curing agent is 0%. The water-cement ratio is 2.0, and the slurry curing agent is composed of water glass, magnesium oxide and cement, and the ratio of the three components is 20:40:40. When the particle size of the solidified particles is 3 cm, under the carbon dioxide pressu...

Embodiment 3

[0059] On the basis of Example 1, when the organic pollutant in the composite polluted soil is benzene, the concentration of benzene in the soil is 5g / kg, and the initial moisture content is about 25%, the minimum temperature when the electric heating plate is set to start is 60°C, That is, when the temperature is lower than 60°C, the electric heating plate is automatically activated, the pumping time is 60 minutes, and the removal rate of organic pollutants is more than 90%. When the gasoline in the polluted soil is volatilized, the moisture content of the polluted soil is 8%-10%, the powder curing agent added to the heavy metal polluted soil is 5%, the slurry curing agent added is 20%, and the slurry curing agent is The water-cement ratio is 2.0, the powder curing agent is magnesium oxide, calcium oxide and cement, and the ratio of the three is 40:20:40; the slurry curing agent is composed of water glass, magnesium oxide and cement, and the ratio of the three components is 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com