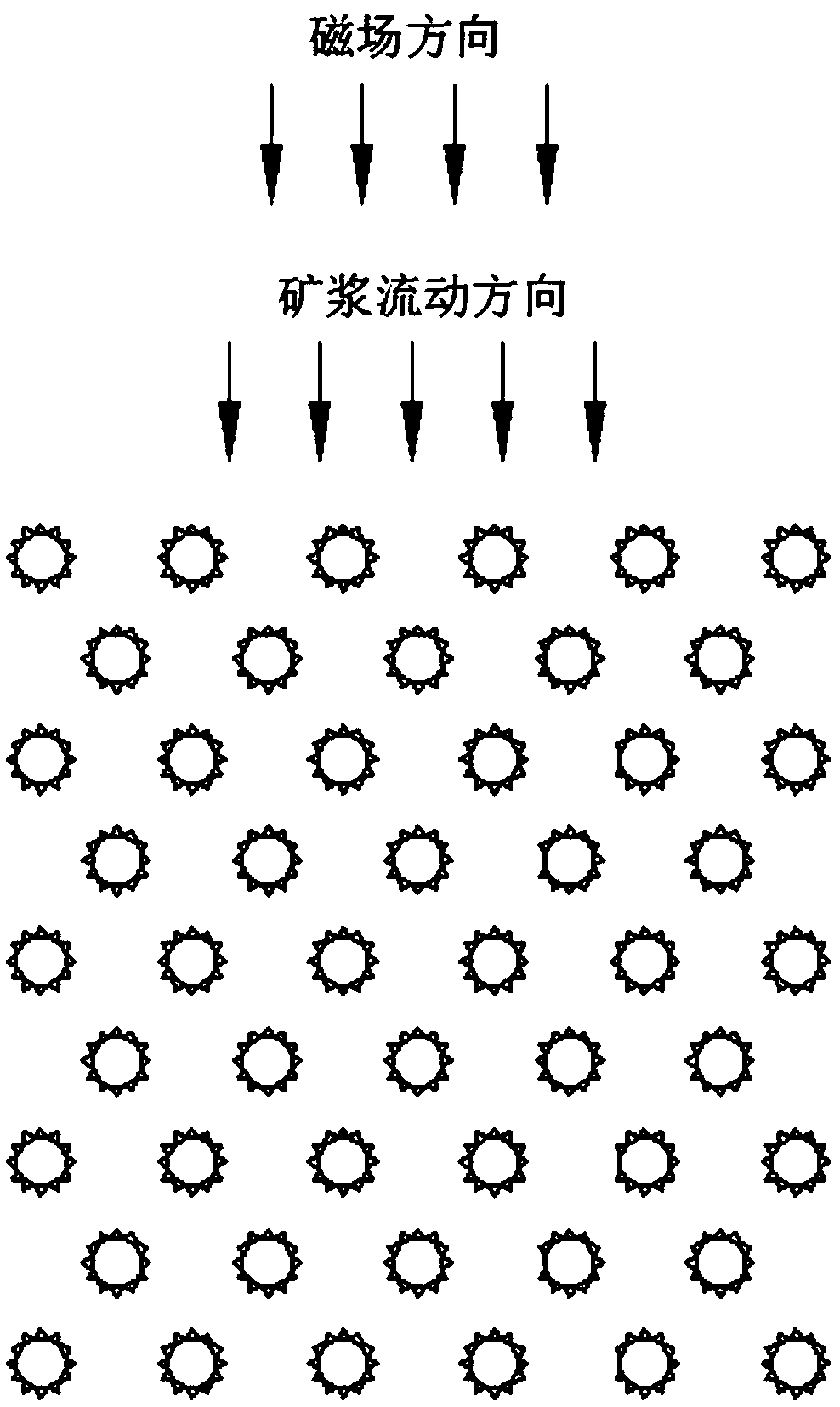

Cassava starch pretreatment-special-shaped medium magnetic separation process

A cassava starch and pretreatment technology, applied in the direction of magnetic separation, high-gradient magnetic separator, solid separation, etc., can solve the problems of iron ore resource loss, difficult mineral resource sorting, etc., achieve large magnetic field force, strengthen recovery, and process The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

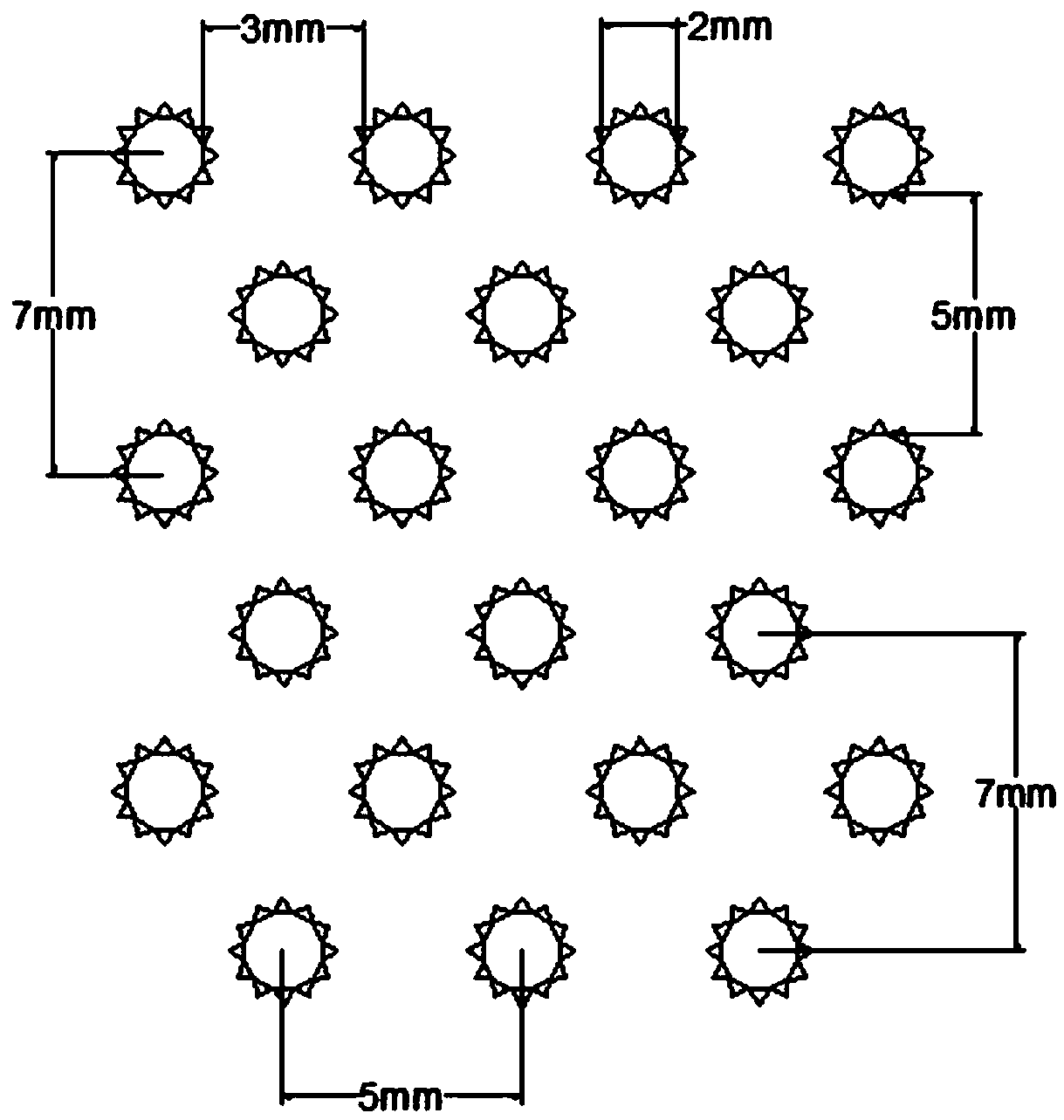

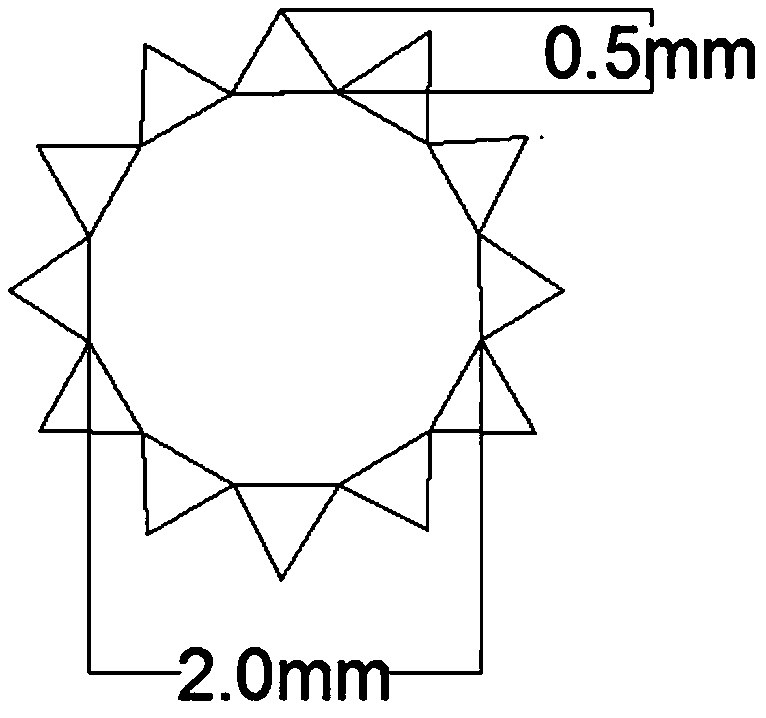

Method used

Image

Examples

Embodiment 1

[0030] (1)取两份TFe品位分别为26.65%,26.61%,浓度为33%,粒度为-0.038mm占95%以上含弱磁性铁矿物的矿浆,在搅拌转速为1000r / min的条件下,加入质量浓度为2%的NaOH溶液匀速搅拌5min,调节矿浆pH值为10.0。

[0031] (2)降低搅拌转速至650r / min,在两份矿浆中均加入对铁矿物具有选择性絮凝作用的木薯淀粉溶液,匀速搅拌5min,使矿浆中的铁矿物通过木薯淀粉的桥联作用形成具有一定强度、大小适中的弱磁性铁矿物絮团,从而增加铁矿物在磁选过程中的捕获概率其中,所述矿浆与木薯淀粉溶液的质量比为50:1。

[0032] (3)将其中一份矿浆给入到含有异形介质的立环高梯度磁选机进行分选,将另一份矿浆给入到含有常规圆棒介质的立环高梯度磁选机进行分选。在背景场强为7000奥斯特,脉动冲程为15mm,脉动冲次为200次 / min、矿浆流速0.03m / s的条件下进行一次强磁粗选作业,其中采用木薯淀粉预处理-异形磁介质联合新工艺可以获得铁品位为42.26%,铁回收率为43.69%的强磁粗选磁性产物;采用木薯淀粉预处理-常规圆棒介质强磁选工艺获得的磁性产物铁品位为42.36%,铁回收率为40.88%。

[0033] (4)将两份强磁粗选尾矿在背景场强为10000奥斯特,脉动冲程为15mm,脉动冲次为150次 / min、矿浆流速0.03m / s的条件下进行两次扫选,将两次扫选磁性产物与粗选磁性产物混合,其中采用木薯淀粉预处理-异形磁介质强磁选工艺可以获得最终铁品位为42.35%,铁回收率为75.76%的强磁选磁性产物以及含铁品位为12.55%的扫选尾矿产品;常规强磁选工艺获得最终铁品位为40.61%,铁回收率为71.28%的强磁选磁性产物以及含铁品位为13.56%的扫选尾矿产品。

Embodiment 2

[0035] (1)取两份TFe品位分别为26.85%,26.71%,浓度为33%,粒度为-0.038mm占95%以上含弱磁性铁矿物的矿浆,在搅拌转速为1000r / min的条件下,加入质量浓度为2%的NaOH溶液匀速搅拌5min,调节矿浆pH值为9.5。

[0036](2) Reduce the stirring speed to 650r / min, add cassava starch solution which has selective flocculation effect on iron minerals to both pulps, and stir at a constant speed for 5min, so that the iron minerals in the pulp can pass through the bridging effect of cassava starch Weakly magnetic iron mineral flocs with certain strength and moderate size are formed, thereby increasing the capture probability of iron minerals in the magnetic separation process, wherein the mass ratio of the pulp to tapioca starch solution is 40:1.

[0037] (3) One part of the pulp is fed to the vertical ring high gradient magnetic separator containing special-shaped media for separation, and the other part of the pulp is fed to the vertical ring high gradient magnetic separator containing conventional round rod media for separation . Under the conditions of backgroun...

Embodiment 3

[0040] (1) Get two parts of TFe grades and be respectively 26.85%, 26.77%, concentration is 30%, particle size is - 0.038mm accounts for more than 95% ore pulp containing weak magnetic iron minerals, under the condition that stirring speed is 1000r / min, add The NaOH solution with a mass concentration of 2% was stirred at a constant speed for 5 minutes, and the pH value of the slurry was adjusted to 9.0.

[0041] (2) Reduce the stirring speed to 600r / min, add cassava starch solution to one part of the pulp, and stir at a constant speed for 5 minutes, so that the iron minerals in the pulp can form a weak magnetic iron with a certain strength and a moderate size through the bridging effect of cassava starch. Mineral flocculation, thereby increasing the capture probability of iron minerals in the magnetic separation process, wherein, the mass ratio of described ore pulp and tapioca starch solution is 40:1; In another part of ore pulp, do not add tapioca starch solution, stir at a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com