Waste gas purification method

A waste gas purification and waste gas technology, which is applied in the direction of chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of less purification methods of organic waste gas and acid waste gas, environmental impact, corrosive or irritating odor and carcinogenicity, and achieve absorption The effect of outstanding effect, quick response, and lightening of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

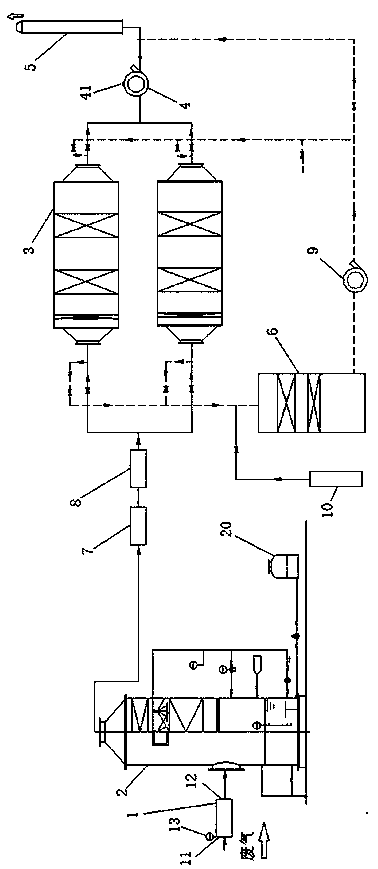

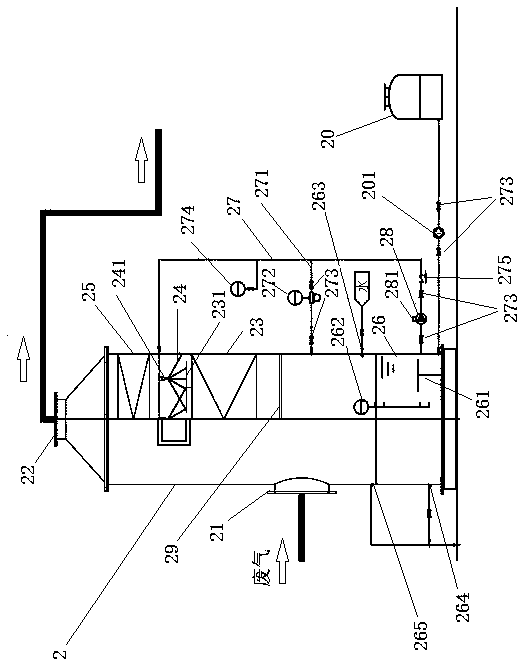

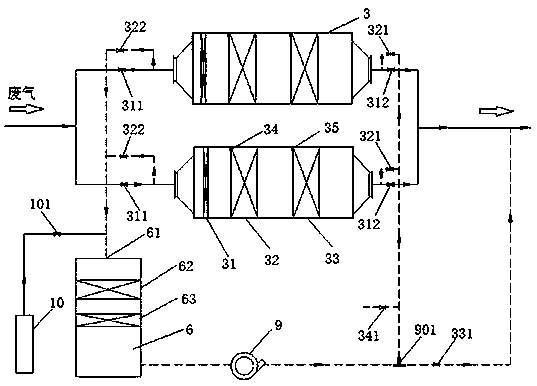

[0037] The present invention will now be further described in detail with reference to the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0038] like Figure 1-3 As shown, an exhaust gas purification method is characterized in that: comprising:

[0039] (1) Exhaust gas pretreatment

[0040] The exhaust gas first passes through the heating device 1, and the gas is heated to 50-80 °C, which not only effectively increases the reaction activity of the exhaust gas molecules, thereby significantly promoting the reaction of the exhaust gas with the absorption treatment liquid after entering the exhaust gas washing tower, without excessively increasing the energy. consumption. At the same time, after the exhaust gas is heated, the upward trend of the gas increases, thereby reducing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com