Hotpot condiment and preparation method thereof

A hot pot base and frying technology, which is applied in the field of food seasonings, can solve the problems of affecting the taste of the hot pot base, low stirring and frying efficiency, and low degree of automation, and achieves high frying efficiency, high degree of automation, and increased stirring. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A hot pot bottom material and a preparation method thereof. The raw materials required by the method include: in parts by weight, 800-1200 parts of butter, 150-250 parts of vegetable oil, 600-1000 parts of pepper, and 70-120 parts of bean paste. 7-12 parts of salt, 150-230 parts of pepper, 20-40 parts of ginger, 30-50 parts of garlic, 15-25 parts of tempeh, 15-25 parts of chicken essence, 2-5 parts of rock sugar, 15-25 parts of cooking wine, peas 20-40 parts, 15-25 parts of turmeric, 20-40 parts of white cardamom, 70-120 parts of scallion white, wherein, the preparation method comprises the following steps:

[0035] Step (1) Weighing raw materials: Weighing raw materials according to the above ratio of parts by weight;

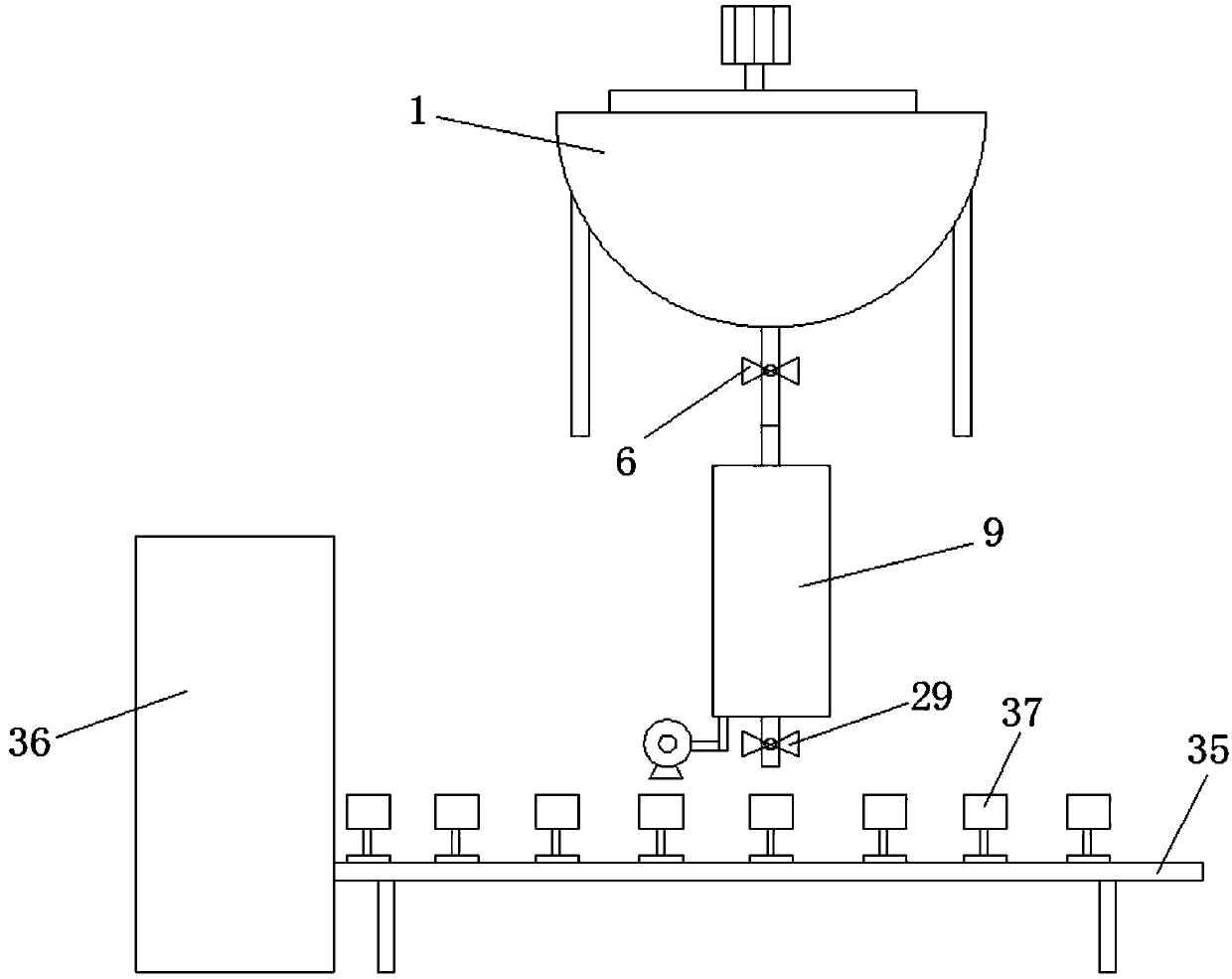

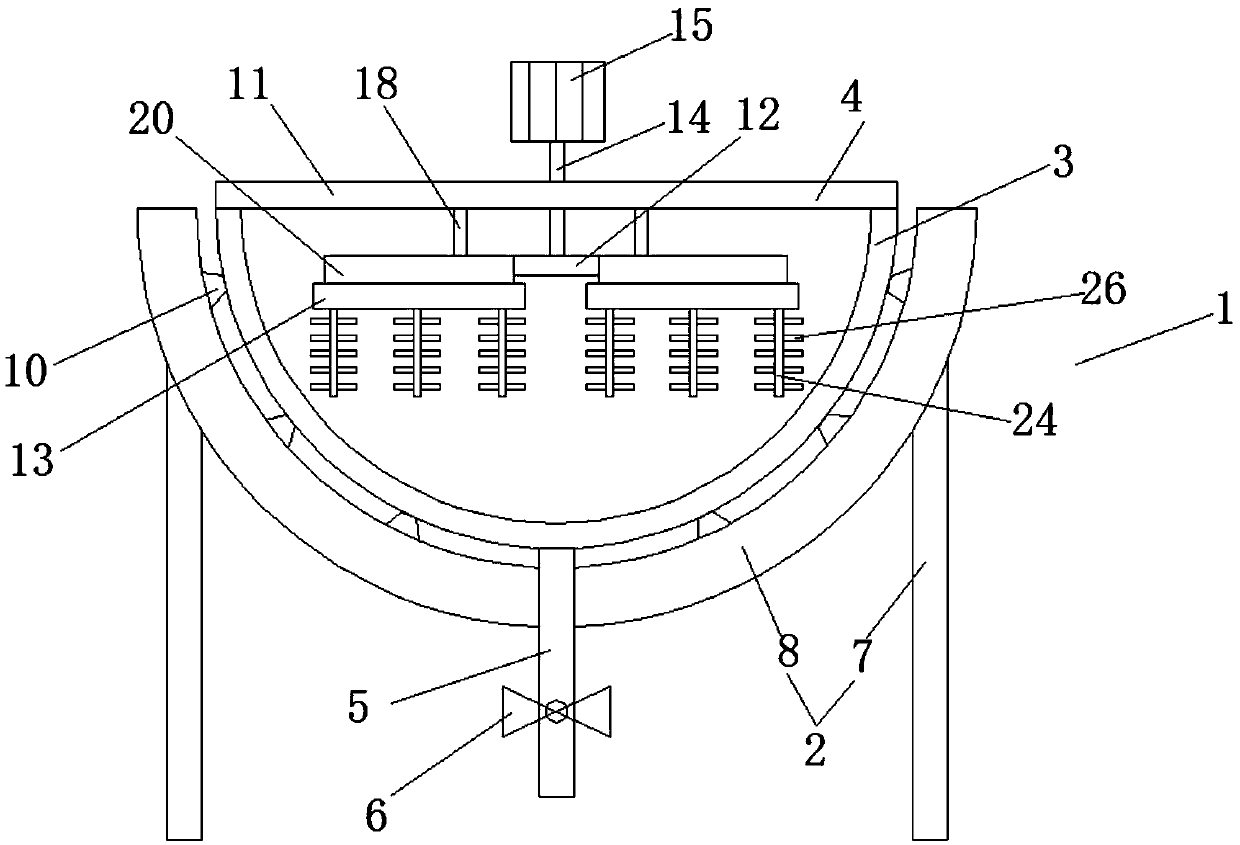

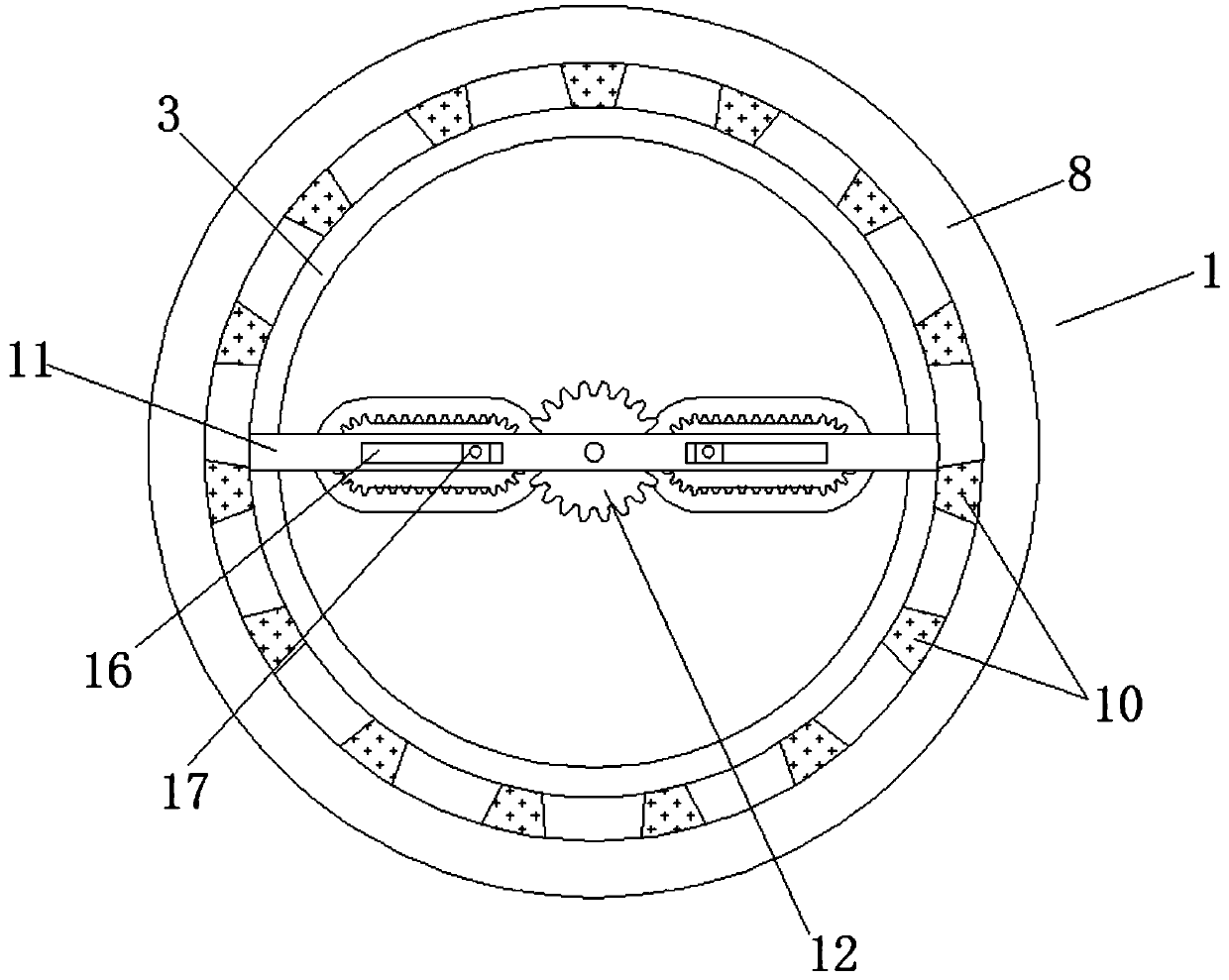

[0036] Step (2) Heating: Add butter and vegetable oil to frying device 1, and heat the butter and vegetable oil to 80-150°C;

[0037] Step (3) Initial frying: Add bean paste, green onion, tempeh, rock sugar, pepper, turmeric, and old ginger to the fryi...

Embodiment 2

[0050] It is basically the same as the above embodiment, the difference is:

[0051] The preparation method of described chafing dish bottom material is as follows:

[0052] Step (1) Weigh raw materials: by weight, weigh 1,000 parts of butter, 200 parts of vegetable oil, 800 parts of pepper, 100 parts of bean paste, 10 parts of edible salt, 200 parts of peppercorns, 30 parts of ginger, and 40 parts of garlic. 40 servings, 20 servings of tempeh, 20 servings of chicken essence, 3 servings of rock sugar, 20 servings of cooking wine, 30 servings of peas, 20 servings of turmeric, 30 servings of white cardamom, 100 servings of scallion white;

[0053] Step (2) Heating: Add butter and vegetable oil to frying device 1, and heat the butter and vegetable oil to 90°C;

[0054] Step (3) Initial frying: Add bean paste, green onion, tempeh, rock sugar, pepper, turmeric, and old ginger to the frying device 1, first keep frying at 110°C for 40 minutes, and then keep frying at 50°C for 60 min...

Embodiment 3

[0059] It is basically the same as the above embodiment, the difference is:

[0060] The preparation method of described chafing dish bottom material is as follows:

[0061] Step (1) Weigh raw materials: by weight, weigh 800 parts of butter, 160 parts of vegetable oil, 640 parts of pepper, 80 parts of bean paste, 8 parts of edible salt, 160 parts of Chinese prickly ash, 24 parts of ginger, 32 parts of garlic 16 parts of soy sauce, 16 parts of chicken essence, 2.4 parts of rock sugar, 16 parts of cooking wine, 24 parts of peas, 16 parts of turmeric, 24 parts of white cardamom, 80 parts of scallion white;

[0062] Step (2) Heating: Add butter and vegetable oil to frying device 1, and heat the butter and vegetable oil to 100°C;

[0063] Step (3) Initial frying: Add bean paste, green onion, fermented soybeans, rock sugar, pepper, turmeric, and old ginger to the frying device 1, first keep frying at 110°C for 30 minutes, and then keep frying at 40°C for 60 minutes;

[0064] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com