Colored photosensitive resin composition, color filter and display device

A technology of photosensitive resin and composition, applied in the direction of instruments, optics, filters, etc., can solve the problem that the technology cannot fully meet the characteristics and other problems, achieve excellent color reproduction characteristics, prevent the loss of fine patterns, and excellent undercut characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0188] Production Example 1. Production of Pigment Dispersion Composition

[0189]

[0190] 10.1 parts by mass of C.I. Pigment Green 7, 2.7 parts by mass of C.I. Pigment Yellow 138, 7.2 parts by mass of DISPERBYK-2001 (manufactured by BYK) as a pigment dispersant, 78 parts by mass of propylene glycol methyl as a solvent The ether acetate was mixed / dispersed for 12 hours using a bead mill to prepare pigment dispersion composition M1.

[0191]

[0192] 10.1 parts by mass of C.I. Pigment Green 58 as a pigment, 2.7 parts by mass of C.I. Pigment Yellow 138, 7.2 parts by mass of DISPERBYK-2001 (manufactured by BYK) as a pigment dispersant, 78 parts by mass of propylene glycol methyl as a solvent The methyl ether acetate was mixed / dispersed for 12 hours using a bead mill to prepare a pigment dispersion composition M2.

[0193]

[0194] 10.1 parts by mass of C.I. Pigment Green 59 as a pigment, 2.7 parts by mass of C.I. Pigment Yellow 138, 7.2 parts by mass of DISPERBYK-2001 (ma...

manufacture example 2

[0195] Production example 2: Production of alkali-soluble resin

Synthetic example 1

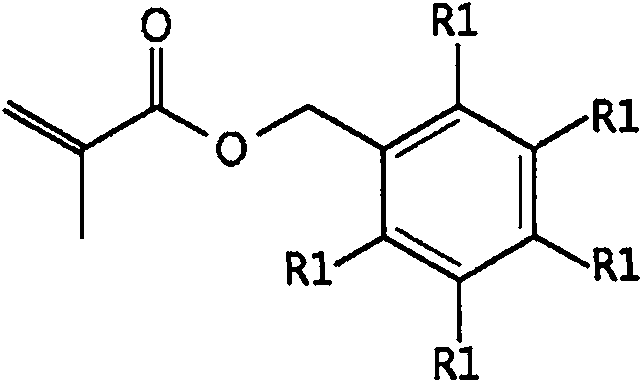

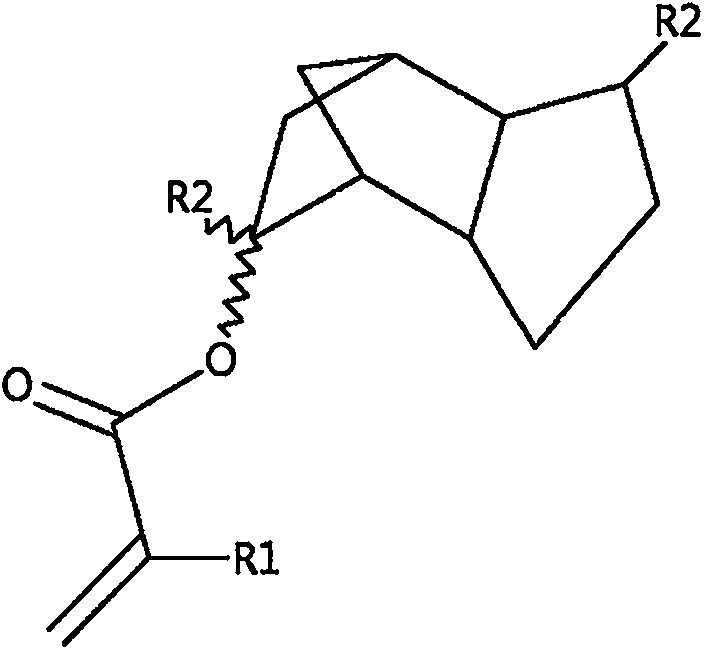

[0196] Synthesis Example 1: Synthesis of A-1

[0197] In a 1000ml flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel and a nitrogen inlet tube, 400 parts by mass of propyl glycol monomethyl ether acetate, 7 parts of AIBN, benzyl methacrylate (BzMA , chemical formula 4) 50 mass parts, tricyclodecane skeleton monomethacrylate (Hitachi Chemical Co., Ltd. manufacture FA-513M) (TCDMA) 63 mass parts, methacrylate 20 mass parts, methacrylic acid 20 mass parts parts, and replaced with nitrogen. Thereafter, the temperature of the reaction liquid was raised to 120° C. while stirring, and the reaction was carried out for 15 hours after the temperature was raised. The alkali-soluble resin thus synthesized had a final solid content of 38.8%, a solid content acid value of 80 mgKOH / g, and a weight average molecular weight measured by GPC of 27,000.

[0198] [chemical formula 4]

[0199]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com