Thermal conductivity meter for vacuum glass

A technology of vacuum glass and thermal conductivity meter, which is applied in the direction of material thermal development, etc., can solve the problems of small thermal conductivity of vacuum glass, large error, and difficulty in finding insulation boards, etc., and achieve the effect of eliminating measurement errors and system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

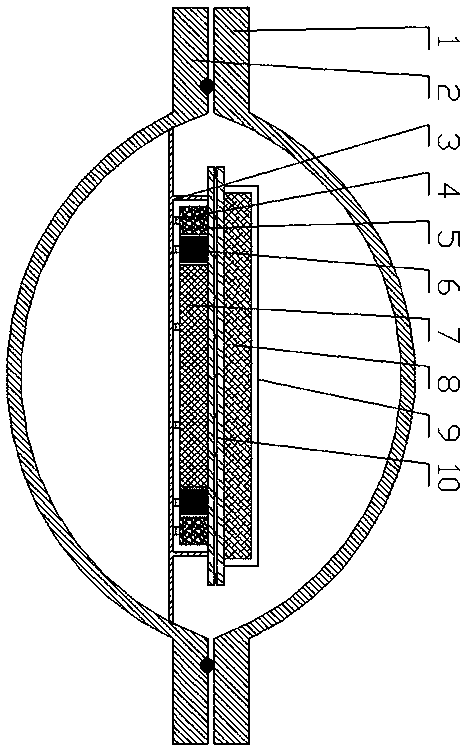

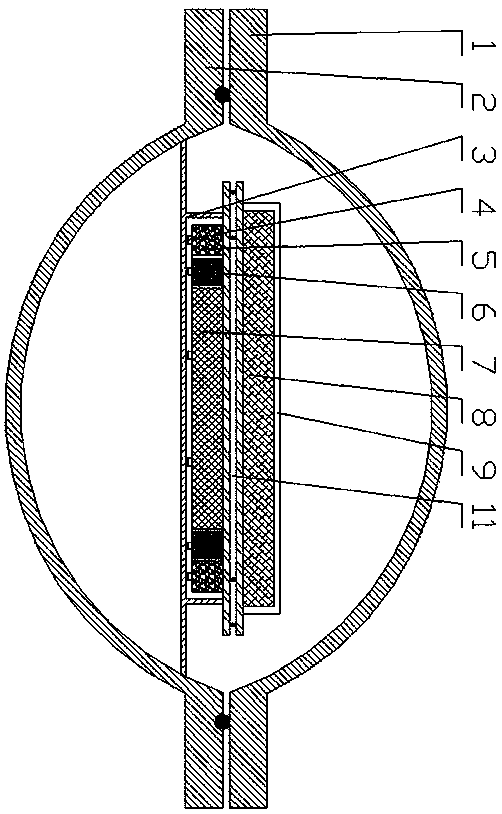

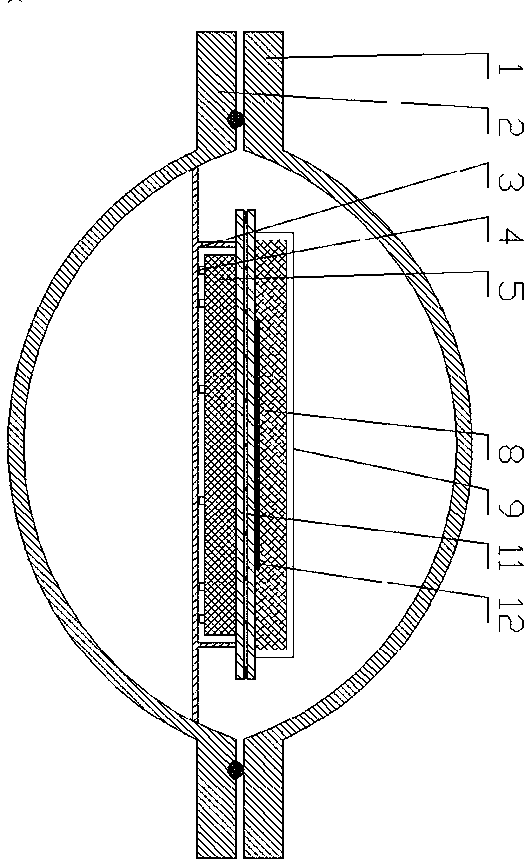

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] Such as figure 1 and figure 2 Shown is an embodiment of measuring the heat conductance of vacuum glass by the protective plate method of the present invention. A vacuum glass thermal conductivity meter is composed of an upper shell 1 and a lower shell 2. After the upper shell 1 and the lower shell 2 are closed, a The rubber sealing ring is sealed, and a high vacuum is formed inside it through a vacuum system; the hot plate is composed of a protective hot plate 5, a buffer hot plate 6 and a measuring hot plate 7, and is installed in the chassis 3 through the heat insulating bracket 4. The heat insulating bracket 4 is elastic and can The hot plate is in close contact with the vacuum glass; the inner surface of the chassis 3 is a low-radiation surface (aluminized, silver or gold, or aluminum foil, etc.), which can isolate radiant heat, and the chassis 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com