Flexible wearable air pressure sensor, preparation method and application thereof

An air pressure sensor, flexible technology, applied in the direction of fluid pressure measurement by changing the ohmic resistance, can solve problems such as inability to bend and deform, fixed structure of the barometer, and inability to apply application requirements, etc., to achieve low cost, simple structure, and convenient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] In some preferred embodiments, the preparation method comprises:

[0070] Prepare flexible top layer and flexible bottom layer respectively;

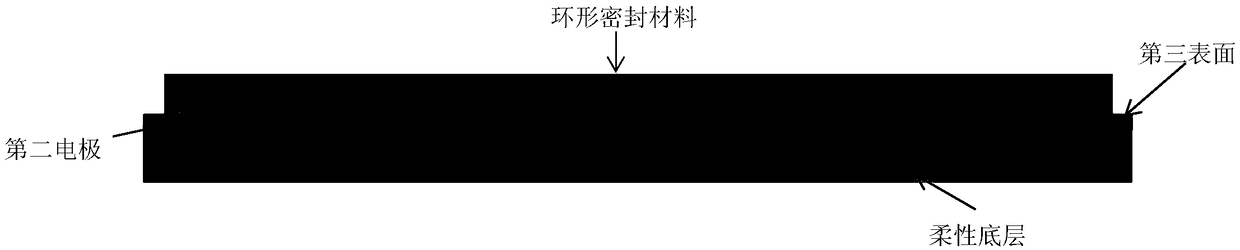

[0071] Coating an annular sealing material on the surface of the flexible bottom layer, and then covering the flexible top layer on the annular sealing material;

[0072] Warm up to the melting temperature of the annular sealing material under vacuum conditions, and keep for a set time, then turn off the heat source, keep the vacuum, and cool naturally, so that the flexible top layer and the flexible bottom layer are bonded under vacuum conditions, so as to be on the second surface. At least a partial area and at least a partial area of the third surface form a sealed air chamber, so that the flexible and wearable air pressure sensor is obtained.

[0073] Different annular sealing materials have different melting temperatures, but when selecting a sealant, it is not easy to choose a material with a melting temperature greater ...

Embodiment 1

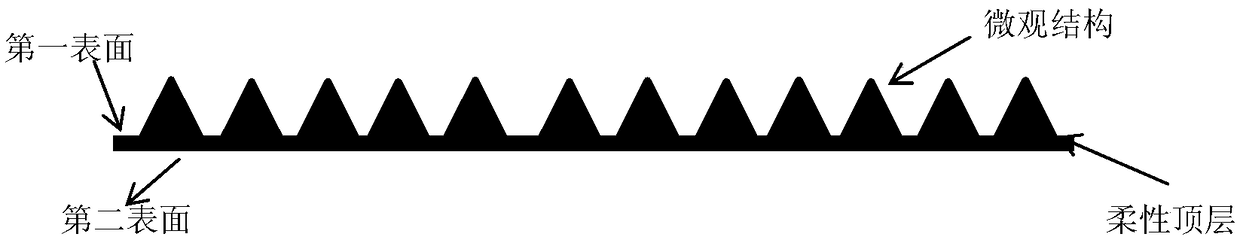

[0115] Mix the PDMS base solution and CNTs (multi-walled carbon nanotubes) at a mass ratio of 100:2, and then prepare a mixed solution with chloroform at a volume ratio of 1:4, and then stir for 12 hours to ensure that the CNTs are evenly mixed In PDMS, the chloroform is completely volatilized by heating, and then the remaining mixture is spin-coated on a silicon wafer with a microstructure to prepare a flexible top layer with a microstructure, such as figure 1 shown. Afterwards, the PET film of a thin layer of ITO is selected to be spin-coated as a flexible bottom layer, and a high-purity paraffin wax with a suitable shape is coated on this layer, such as figure 2 shown. After that, under normal pressure (101KPa), the high-purity paraffin is melted by heating, then the heat source is turned off, the vacuum is kept, and the natural cooling makes the flexible top layer and the flexible bottom layer stick naturally, such as image 3 As shown, finally a flexible wearable air p...

Embodiment 2

[0118] Mix the PDMS base solution and CNTs (multi-walled carbon nanotubes) at a mass ratio of 100:2, and then prepare a mixed solution with chloroform at a volume ratio of 1:4, and then stir for 12 hours to ensure that the CNTs are evenly mixed In PDMS, the chloroform is completely volatilized by heating, and then the remaining mixture is spin-coated on a silicon wafer with a microstructure to prepare a flexible top layer with a microstructure, such as figure 1 shown. Afterwards, the PET film of a thin layer of ITO is selected to be spin-coated as a flexible bottom layer, and a high-purity paraffin wax with a suitable shape is coated on this layer, such as figure 2 shown. Then, under the condition of vacuum degree of 100Pa, the high-purity paraffin wax is melted by heating, then the heat source is turned off, the vacuum is maintained, and natural cooling is made, so that the flexible top layer and the flexible bottom layer are naturally pasted, such as image 3 As shown, fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com