VPH transmissive spectrometer spectral line bend correction system

A bending correction and spectrometer technology, applied in the field of spectroscopy, can solve the problems of high cost of prism grating, unfavorable promotion, affecting the spectral resolution and spatial resolution of the system, and achieve the effect of simple light speed and solving the problem of spectral line bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

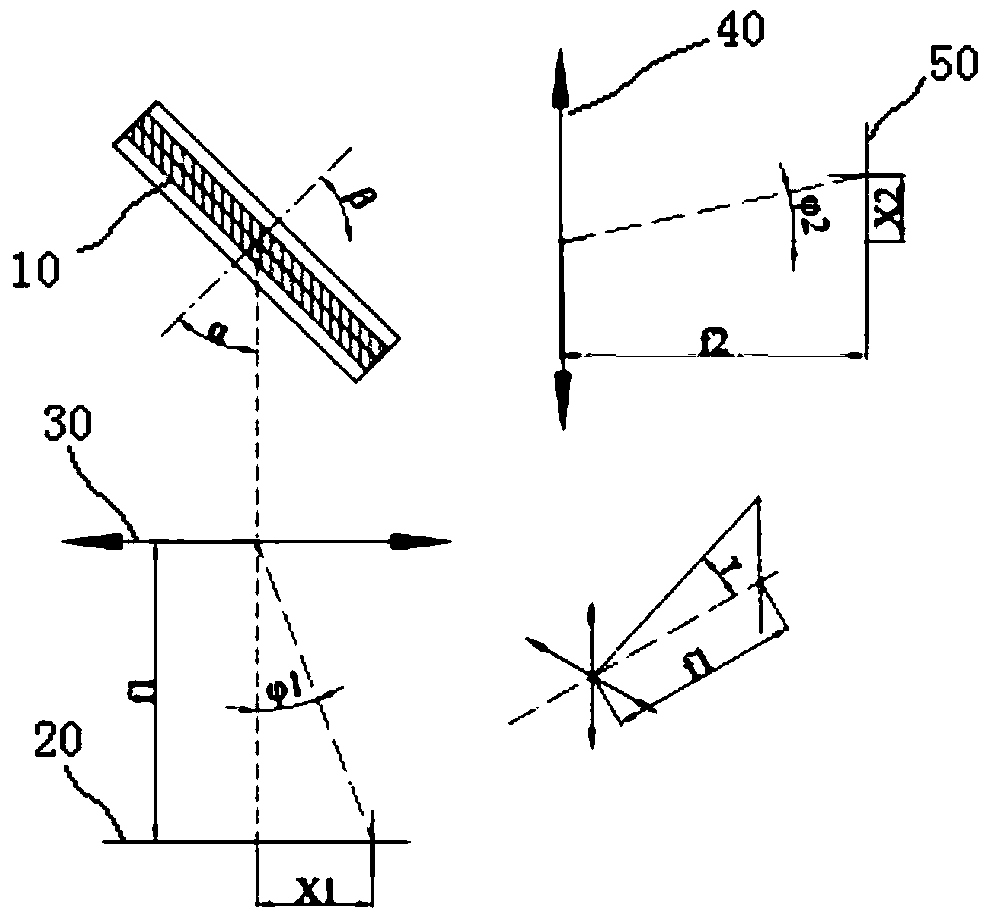

[0012] figure 1 The optical schematic diagram of a typical VPH system is shown, where f1 is the length of the incident arm; f2 is the length of the exit arm; α is the incident angle of the grating; β is the diffraction angle of the grating; X1 is the distance from the main optical axis in the horizontal direction of the incident slit; Φ1 is the angle of the incident slit from the main optical axis in the horizontal direction; X2 is the distance of the diffraction spot from the main optical axis in the horizontal direction; Φ2 is the angle of the diffraction spot from the main optical axis in the horizontal direction; horn.

[0013] Design Optical System

[0014] The diffraction equation of the grating is:

[0015] Νmλ=cos(γ)(sin(α+φ1)+(sin(β+φ2)))

[0016] N is the linear density of the grating, λ is the wavelength of the incident light, and m is the diffraction order of the grating.

[0017] On the main optical axis, Φ1=Φ1=γ=0, the diffraction equation of the grating is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com