A joint grout stop device for steel-concrete combined section and its construction method

A steel-concrete combination and construction method technology, which is applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problem that the slurry stop method cannot be extended, and achieve strong overall slurry resistance, improved stability, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

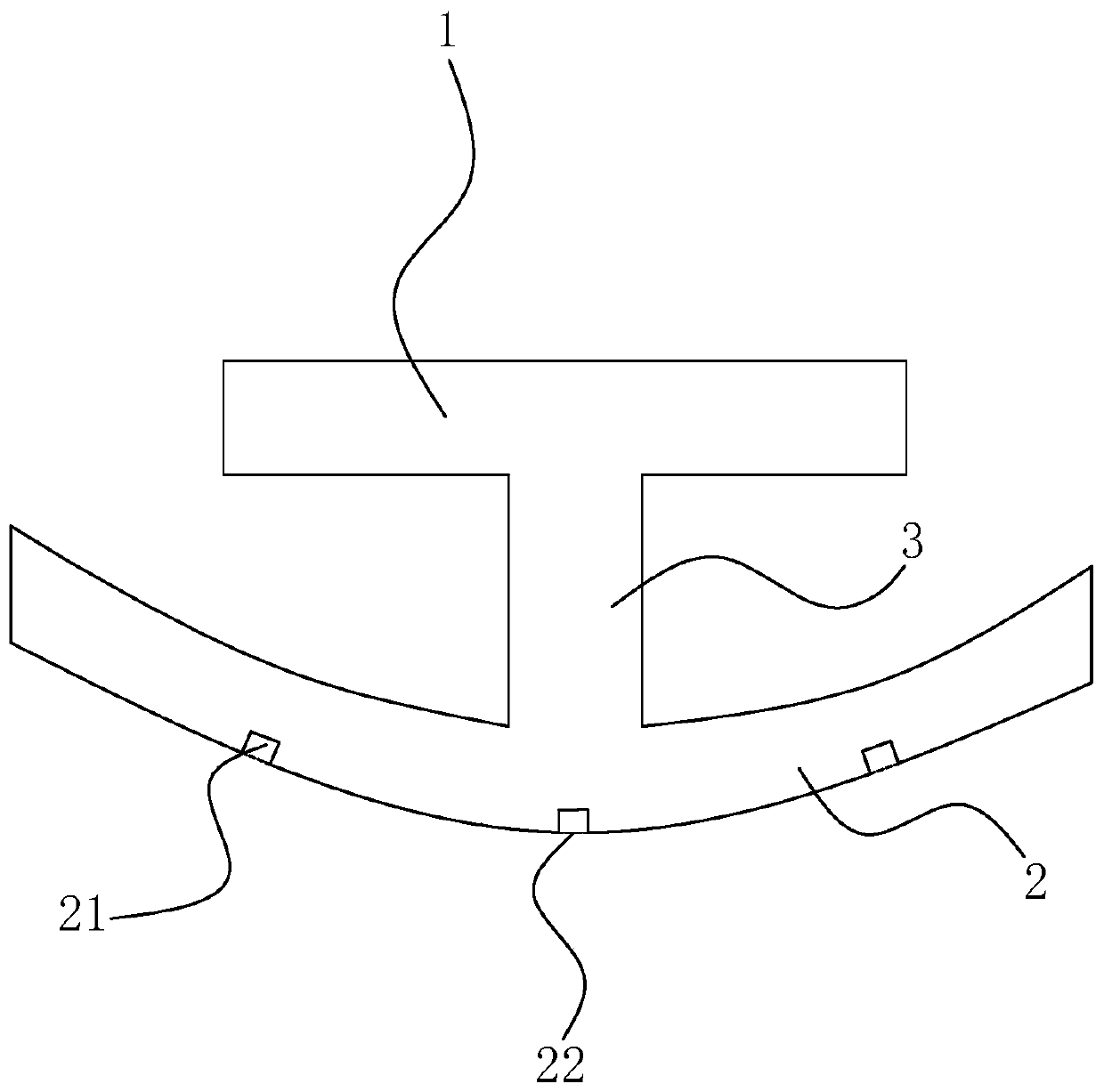

[0043] A joint grout stop device for a steel-concrete joint section, such as figure 1As shown, when the steel structure of the steel-concrete joint section is installed, the hanging basket and the side formwork have been removed, including the upper wing plate 1, and the lower wing plate 2 is arranged in parallel below the upper wing plate 1, and the upper wing plate 1 and The center of the lower wing plate 2 is connected with a vertical support plate 3, so that the entire seam stopper is I-shaped. At the same time, the lower wing plate 2 is U-shaped, with the opening facing the upper wing plate 1, and is made of polyurethane water-swellable elastic waterproof material. This type of material not only has elasticity and extensibility similar to rubber, but also The performance of expansion has the effects of elasticity, waterproof, sealing and anti-sizing, so that it can not only save the amount of materials, but also eliminate the shortcomings of elastic fatigue and abrasion a...

Embodiment 2

[0049] A construction method applied to embodiment 1, comprising the following steps:

[0050] S1. By installing a laser transmitter and a receiving board at the interface of the steel-concrete joint section on both sides, the bottom of the laser transmitter is equipped with a slide rail flush with the joint, and the receiving board on the other side is at the same level as the interface. In the plane, adjust the position of the laser transmitter on the slide rail so that the light emitted by the laser transmitter is irradiated on the center of the receiving plate, so as to obtain the actual connection between the steel box girder and the overhanging block in the on-site steel-concrete joint section. Seam distance;

[0051] S2, select the width of upper wing plate 1 and lower wing plate 2 according to the distance measured by S1, make the width of upper wing plate 1 increase 50-60cm on the basis of the measured distance, so that the upper wing plate 1 on the seam surface is su...

Embodiment 3

[0057] A construction method applied to embodiment 1, comprising the following steps:

[0058] S1. By installing a laser transmitter and a receiving board at the interface of the steel-concrete joint section on both sides, the bottom of the laser transmitter is equipped with a slide rail flush with the joint, and the receiving board on the other side is at the same level as the interface. In the plane, adjust the position of the laser transmitter on the slide rail so that the light emitted by the laser transmitter is irradiated on the center of the receiving plate, so as to obtain the actual connection between the steel box girder and the overhanging block in the on-site steel-concrete joint section. Seam distance;

[0059] S2. Select the width of the upper wing plate 1 and the lower wing plate 2 according to the distance measured by S1, so that the width of the upper wing plate 1 is increased by 55 cm on the basis of the measured distance, so that the force of the upper wing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com