Mixed polyurethane crosslinked foam material and preparation method thereof

A technology of mixing polyurethane and Lianfa, which is applied in the field of foaming materials, can solve the problems of high compression set, poor elasticity, and poor shrinkage performance, and achieve low compression set, good elasticity, and good shrinkage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

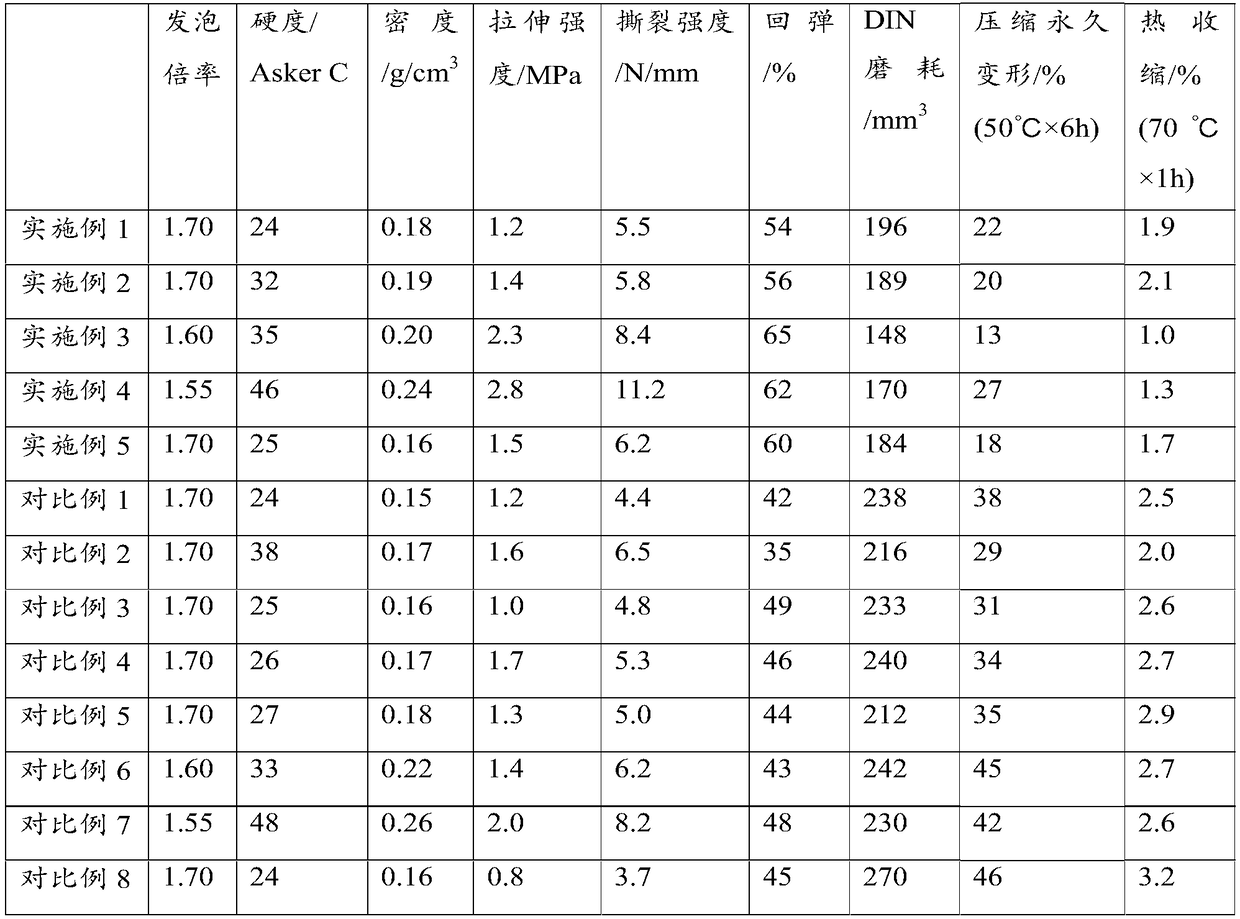

Examples

preparation example Construction

[0075] According to another aspect of the present invention, the present invention provides the preparation method of above-mentioned mixing type polyurethane cross-linked foaming material, comprises the steps:

[0076] (a) mixing the mixing type polyurethane, vinyl copolymer, foaming agent, crosslinking agent, optional reinforcing agent and optional filler uniformly, performing banburying and kneading in sequence to obtain a kneaded product;

[0077] (b) extruding and granulating the kneaded product to obtain cross-linked foamed granules;

[0078] (e) Putting the cross-linked foamed particles into a mold for cross-linked foaming to obtain a mixing-type polyurethane cross-linked foamed material.

[0079] The preparation method of the mixing-type polyurethane cross-linked foaming material provided by the invention is simple to operate, does not require high operating proficiency of equipment and staff, can effectively reduce manufacturing costs, and improve production efficienc...

Embodiment 1

[0098]This embodiment provides a mixing type polyurethane cross-linked foaming material, which is made of the following raw materials in parts by mass: 20 parts of mixing type polyurethane, 80 parts of ethylene-vinyl acetate copolymer (EVA), foaming 4 parts of cross-linking agent and 1 part of cross-linking agent; among them, the mixing type polyurethane is polymerized by polyether butylene glycol, toluene diisocyanate and α-allyl glyceryl ether, and the Mooney viscosity is 50; ethylene-vinyl acetate copolymer The melt index of (EVA) is 10g / min; the cross-linking agent is di-(tert-butylperoxyisopropyl)benzene (DIPB); A composition of nitrosopentamethylenetetramine (DPT), and the mass ratio of the two is 5:3.

Embodiment 2

[0100] This embodiment provides a mixing type polyurethane cross-linked foaming material, which is made of the following raw materials in parts by mass: 90 parts of mixing type polyurethane, 8 parts of ethylene-vinyl acetate copolymer (EVA), polyolefin 2 parts of elastomer (POE), 4.4 parts of foaming agent, 0.6 parts of crosslinking agent; among them, the mixing type polyurethane is polymerized by polyether butylene glycol, p-phenylene diisocyanate and trimethylolpropane monoallyl ether , and the Mooney viscosity is 120; the melt index of ethylene-vinyl acetate copolymer is 1g / min, and the melt index of polyolefin elastomer (POE) is 20g / min; the crosslinking agent is dicumyl peroxide (DCP) The foaming agent is a composition of dicumyl peroxide (DCP) and two-(tert-butylperoxyisopropyl)benzene (BIPB), and the mass ratio of the two is 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com