Polyurea self-repairing thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and self-repairing technology, which is applied in the field of polyurea self-repairing thermoplastic elastomer and its preparation, and the preparation of self-repairing thermoplastic elastomer, can solve the problem of low breaking strength, achieve strong disulfide bond interaction, and produce no Toxic and harmless, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

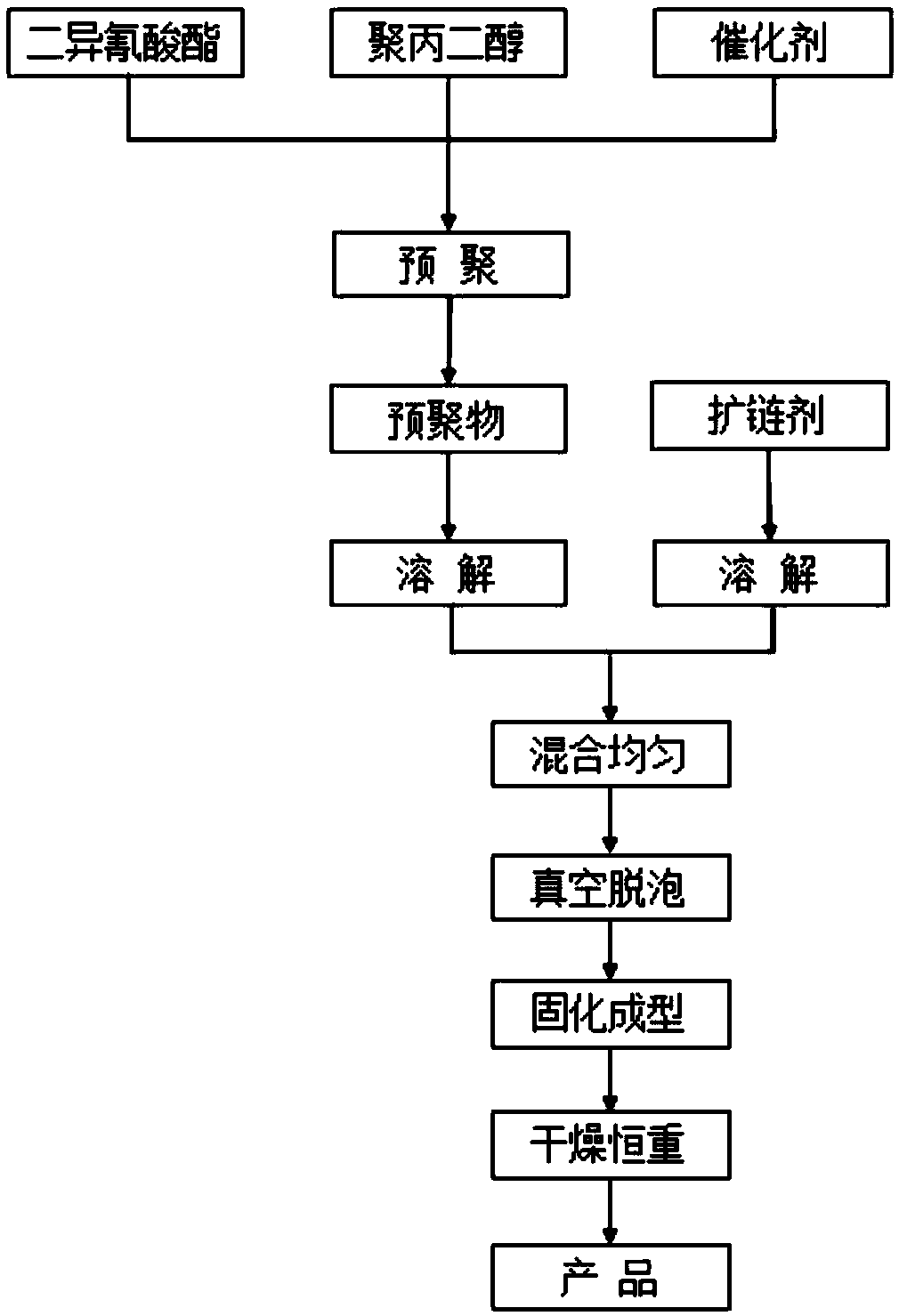

[0035] The preparation method of the polyurea self-healing thermoplastic elastomer of the present invention comprises the following processing steps:

[0036] Step 1, mix and stir 4.42 g 1,6-diisocyanate and 6.00 g polypropylene glycol 400 evenly, add 0.048 g dibutyltin dilaurate, heat and stir in a water bath at 30-35°C for 30-40 min to obtain Prepolymer;

[0037] Step 2, 2.48 g of 2,2'-dithiodianiline was dissolved in 0.62 g of dimethylformamide, sealed for later use;

[0038] Step 3, the prepolymer is dissolved in 4.2 g of dimethylformamide, sealed for subsequent use;

[0039] Step 4: After mixing and stirring the chain extender solution and the prepolymer solution evenly, vacuum defoaming, curing and molding at room temperature, keeping for 1 day, and vacuum drying at 60°C for 3-4 days to constant weight, to obtain polyurea self-healing thermoplastic elastomer.

Embodiment 2

[0041] The preparation method of the polyurea self-healing thermoplastic elastomer of the present invention comprises the following processing steps:

[0042] Step 1, mix and stir 4.42 g 1,6-diisocyanate and 6.00 g polypropylene glycol 400 evenly, add 0.048 g dibutyltin dilaurate, heat and stir in a water bath at 30-35°C for 30-40 min to obtain Prepolymer;

[0043] Step 2, 2.48 g of 4,4'-dithiodianiline was dissolved in 0.62 g of dimethylformamide, sealed for later use;

[0044] Step 3, the prepolymer is dissolved in 4.2 g of dimethylformamide, sealed for subsequent use;

[0045] Step 4: After mixing and stirring the chain extender solution and the prepolymer solution evenly, vacuum defoaming, curing and molding at room temperature, keeping for 1 day, and vacuum drying at 60°C for 3-4 days to constant weight, to obtain polyurea self-healing thermoplastic elastomer.

Embodiment 3

[0047] The preparation method of the polyurea self-healing thermoplastic elastomer of the present invention comprises the following processing steps:

[0048] Step 1, mix and stir 4.42 g 1,6-diisocyanate and 9.00 g polypropylene glycol 600 evenly, add 0.048 g dibutyltin dilaurate, heat and stir in a water bath at 30-35°C for 30-40 min to obtain Prepolymer;

[0049] Step 2, 2.48 g of 4,4'-dithiodianiline was dissolved in 0.62 g of dimethylformamide, sealed for later use;

[0050] Step 3, the prepolymer is dissolved in 5.4 g of dimethylformamide, sealed for subsequent use;

[0051] Step 4: After mixing and stirring the chain extender solution and the prepolymer solution evenly, vacuum defoaming, curing and molding at room temperature, keeping for 1 day, and vacuum drying at 60°C for 3-4 days to constant weight, to obtain polyurea self-healing thermoplastic elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com