A method for preparing six compounds of oxytroflavoside from Oxytropis falciparum and its application

A technology of Oxytropis falciparum and crude extracts, which is applied in organic chemistry, pharmaceutical formulations, drug combinations, etc., can solve the problems of complex and cumbersome extraction methods, poor repeatability, environmental impact, etc., and achieve broad market application prospects, simple operation, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1, Oxytroflavoside A, B, C, D, F, G

[0029] (1) Extraction: Take 2 kg of Oxytropis falciparum and grind it, extract with 60 L of 5% V / V ethanol solution to obtain an extract, and recover the ethanol to obtain a crude extract.

[0030] (2) Impurity removal:

[0031] a Take the above crude extract, filter it with a 0.1μm-0.5μm ceramic membrane (pressure: 3MPa, flow rate 50-500ml / min) to remove fine slag, soil and other impurities;

[0032] b Take the extract obtained in step a, wash it successively with petroleum ether and ethyl acetate, absorb the washed water phase with AB-8 macroporous resin, wash the resin column with water, first elute with 40% ethanol solution to remove impurities, and then Elute with 60% ethanol solution, collect the 60% ethanol eluate, and recover the ethanol to obtain the crude extract.

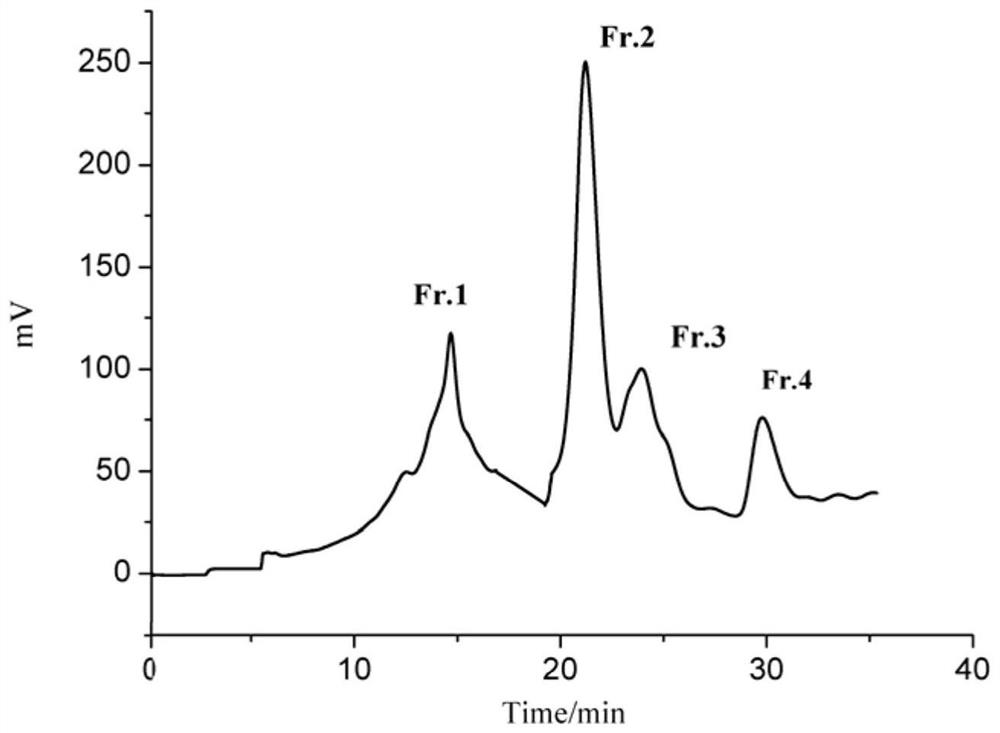

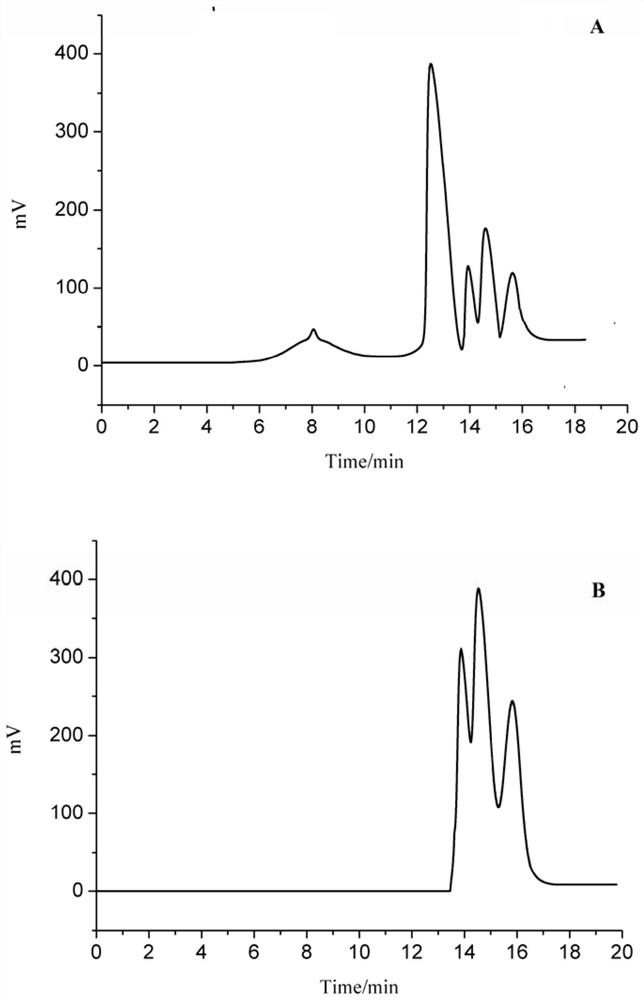

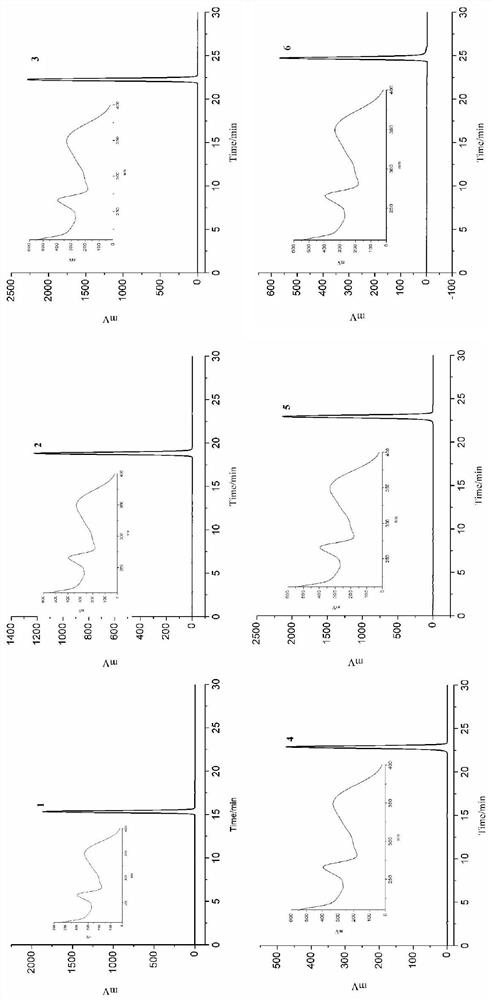

[0033] (3) One-dimensional separation and preparation: take the crude extract obtained in step (2), and use C18 chromatographic...

Embodiment 2

[0040] The preparation of embodiment 2, Oxytroflavoside A, B, C, D, F, G

[0041] (1) Extraction: Take 2 kg of Oxytropis falciparum and grind it, extract with 10 L of 95% V / V ethanol solution to obtain an extract, and recover the ethanol to obtain the extract.

[0042] (2) Impurity removal:

[0043] a Take the above-mentioned extract, add water to dissolve it, filter it with a ceramic membrane of 0.1 μm ~ 0.5 μm (pressure: 3 MPa, flow rate 50 ~ 500ml / min) to remove fine slag, soil and other impurities;

[0044] b Take the extract obtained in step a, wash it successively with petroleum ether and ethyl acetate, absorb the washed water phase with D101 macroporous resin, wash the resin column with water, first elute and remove impurities with 40% ethanol solution, and then use 60 % ethanol solution for elution, collect 60% ethanol eluate, and recover the ethanol to obtain the crude extract.

[0045] (3) One-dimensional separation and preparation: take the crude extract obtained ...

Embodiment 3

[0049] Embodiment 3, the preparation of Oxytroflavoside A, B, C, D, F, G

[0050] (1) Extraction: Take 2kg of Oxytropis falciparum and crush it, extract it with 40L of 50% V / V ethanol solution to obtain the extract, recycle the ethanol to obtain the extract.

[0051] (2) Impurity removal:

[0052] a Take the above-mentioned extract, add water to dissolve it, filter it with a ceramic membrane of 0.1 μm ~ 0.5 μm (pressure: 3 MPa, flow rate 50 ~ 500ml / min) to remove fine slag, soil and other impurities;

[0053] b Take the extract obtained in step a, wash it successively with petroleum ether and ethyl acetate, absorb the washed water phase with D101 macroporous resin, wash the resin column with water, first elute and remove impurities with 40% ethanol solution, and then use 60 % ethanol solution for elution, collect 60% ethanol eluate, and recover the ethanol to obtain the crude extract.

[0054] (3) One-dimensional separation and preparation: take the crude extract obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com