Light emitting material as well as preparation method and light emitting method thereof

A technology of luminescent materials and mixed solutions, which is applied in the direction of luminescent materials, chemical instruments and methods, platinum group organic compounds, etc., can solve the problems of low manufacturing cost, achieve the effects of improving selectivity, simple operation, and increasing reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

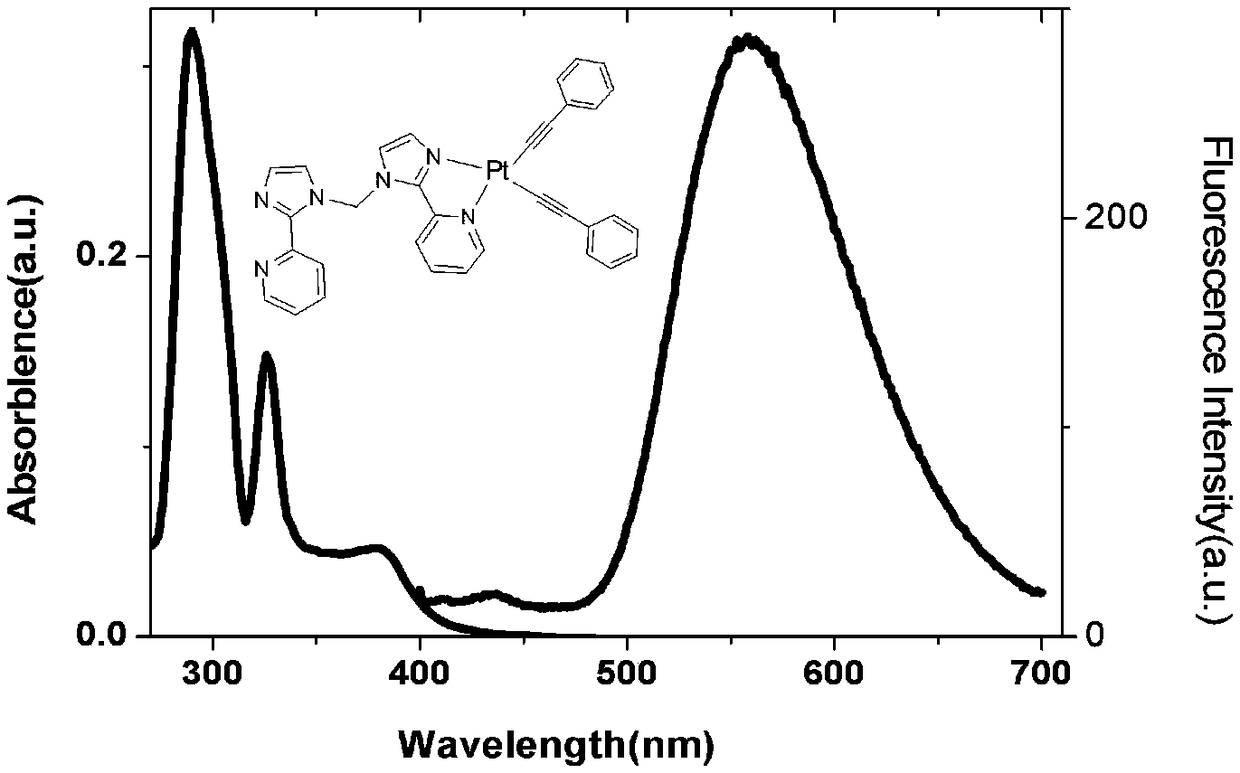

Image

Examples

Embodiment 1

[0021] Embodiment 1 of the present invention provides a preparation method of the target product 3g (N-[(2-pyridyl)imidazolium]methylene-bi(2-pyridyl)imidazoplatin (tolanylacetylene) complex):

[0022] (1) Synthesis of 1g: Weigh 1940mg (13.3mmol) of 2-(2-pyridine) imidazole and grind it into powder, add it to the flask, then add 840mg (15mmol) of KOH and 110mg (0.3mmol) of tetrabutylammonium bromide to the flask ), add 2 to 3 drops of ultrapure water to the flask, and stir the mixture in the flask into an off-white viscous substance, then add 50ml of CH 2 Cl 2 , after stirring and mixing evenly, after reacting at room temperature for 30 hours, the color of the mixed solution becomes light yellow, stop the reaction, heat the mixed solution to evaporate the solvent (the heating temperature is not particularly limited, as long as the solvent can be evaporated) , the remaining solute was eluted with petroleum ether and ethyl acetate at a volume ratio of 1:1, and then separated by...

Embodiment 2

[0031] Example 2 of the present invention provides a preparation method of the target product 3g (N-[(2-pyridyl)imidazolium]methylene-bi(2-pyridyl)imidazoplatin (tolanylacetylene) complex):

[0032] (1) Synthesis of 1g: Weigh 1750mg (12mmol) of 2-(2-pyridine) imidazole and grind it into powder, add it to the flask, then add 728mg (13mmol) of KOH and 37mg (0.1mmol) of tetrabutylammonium bromide to the flask , add 2 to 3 drops of ultrapure water to the flask, and stir the mixture in the flask into an off-white viscous substance, then add 35ml of CH 2 Cl 2 , after stirring and mixing evenly, after reacting at room temperature for 25 hours, the color of the mixed solution turns light yellow, stop the reaction, heat the mixed solution to evaporate the solvent, and use petroleum ether and ethyl acetate with a volume ratio of 1:1 for the remaining solute After elution of the ester and separation by column chromatography, 1 g of off-white crystals was obtained;

[0033] (2) Synthesi...

Embodiment 3

[0037] Example 3 of the present invention provides a preparation method of the target product 3g (N-[(2-pyridyl)imidazolium]methylene-bi(2-pyridyl)imidazoplatin (tolanylacetylene) complex):

[0038] (1) Synthesis of 1g: Weigh 2188mg (15mmol) of 2-(2-pyridine) imidazole and grind it into powder, add it to the flask, then add 1008mg (18mmol) of KOH and 175mg (0.5mmol) of tetrabutylammonium bromide to the flask , add 2 to 3 drops of ultrapure water into the flask, and stir the mixture in the flask into an off-white viscous substance, then add 65ml of CH 2 Cl 2 , after stirring and mixing evenly, after reacting at room temperature for 35 hours, the color of the mixed solution turns light yellow, stop the reaction, heat the mixed solution to evaporate the solvent, and use petroleum ether and ethyl acetate with a volume ratio of 1:1 for the remaining solute After elution of the ester and separation by column chromatography, 1 g of off-white crystals was obtained;

[0039] (2) Synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com