Method for extracting spica prunellae and rosmarinus officinalis acid on basis of response surface processes

A technology based on rosmarinic acid and response surface method, which is applied in the field of extracting rosmarinic acid from Prunella vulgaris based on response surface method, can solve the problems of short cycle, high precision, and no consideration of interaction, etc., and achieve the effect of efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] drying and crushing Prunella vulgaris into 60 meshes to obtain Prunella vulgaris powder;

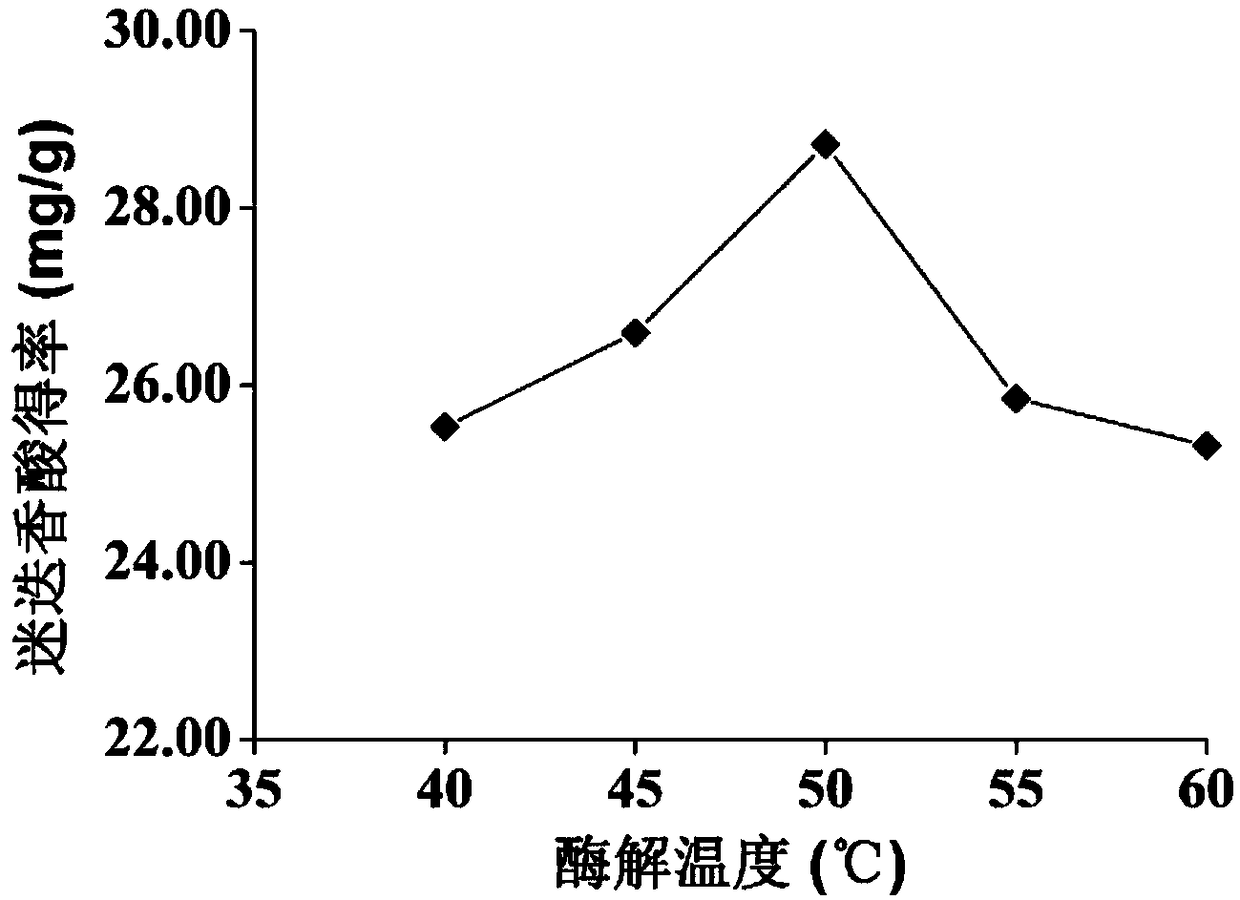

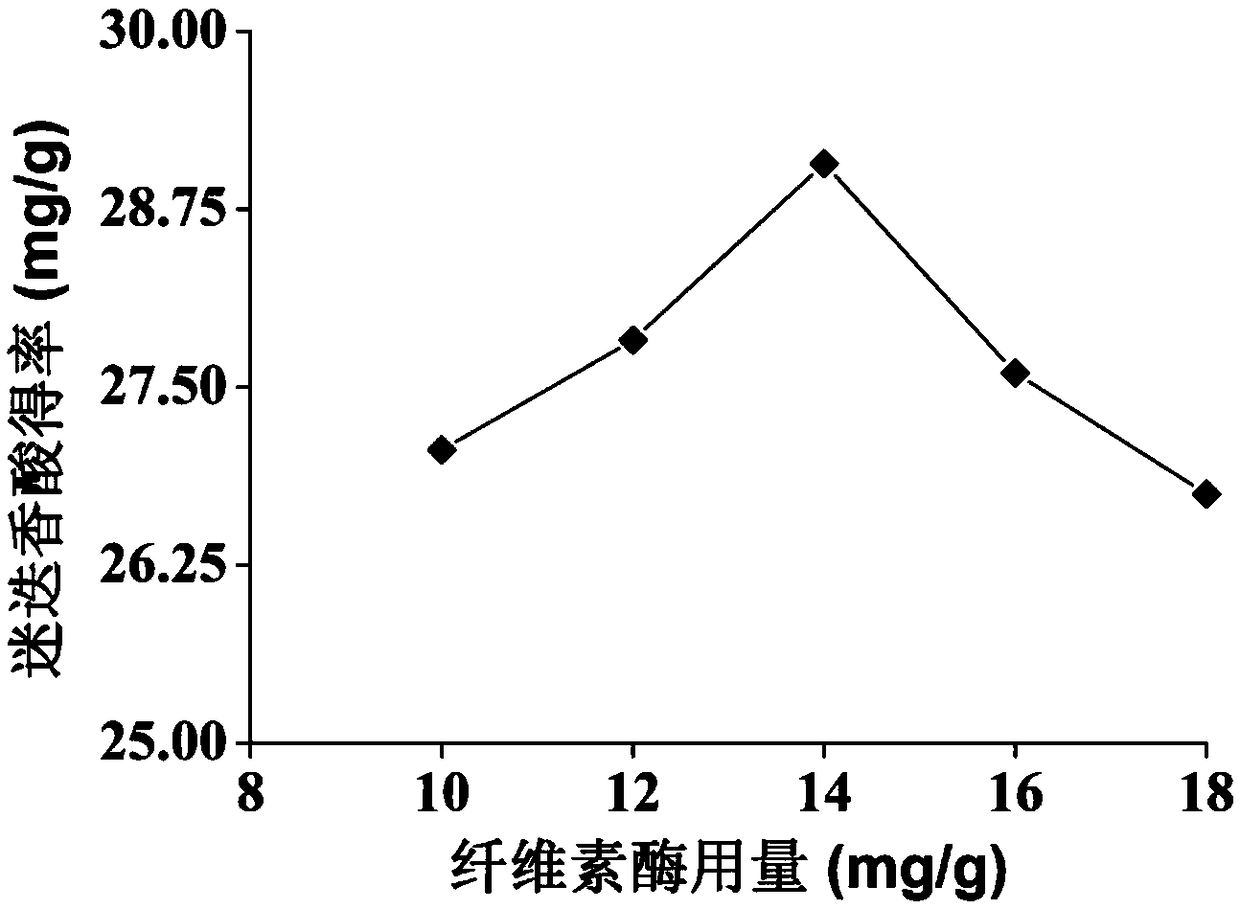

[0038] Weigh 20.0000g of Prunella vulgaris powder, add acetic acid-sodium acetate buffer solution, enzymatically hydrolyze for 2 hours under the conditions of enzymolysis temperature 50°C, enzymolysis pH value 4.0, cellulase dosage 16mg / g, and filter the enzymolysis material , to obtain crude extract;

[0039] Concentrate the crude extract to a thick paste with a rotary evaporator, and dry it in a vacuum oven for 24 hours to obtain the crude extract.

[0040] Take above-mentioned crude thing by weighing, adopt anhydrous methanol to dissolve, after dilution, adopt high performance liquid chromatography to measure Prunella vulgaris rosmarinic acid, and according to rosmarinic acid yield Y=[(rosmarinic acid content × extract weight) / Prunella vulgaris medicinal material weight]×100%. The calculated yield of rosmarinic acid was 20.25 mg / g.

Embodiment 2

[0042] drying and crushing Prunella vulgaris into 60 meshes to obtain Prunella vulgaris powder;

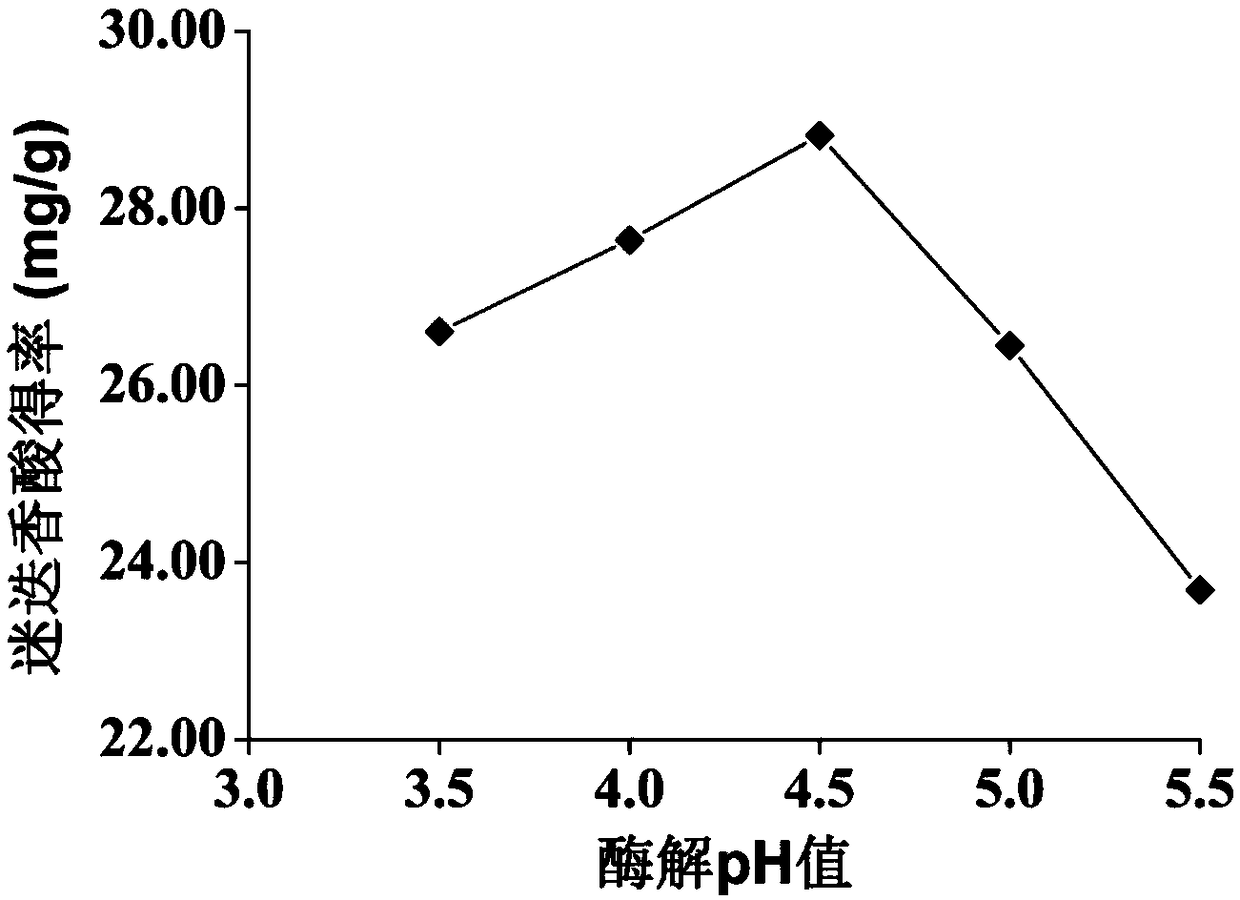

[0043] Weigh 20.0000g of Prunella vulgaris powder, add acetic acid-sodium acetate buffer solution, enzymatically hydrolyze for 2 hours under the conditions of enzymolysis temperature 45°C, enzymolysis pH value 4.5, cellulase dosage 12mg / g, and filter the enzymolysis material , to obtain crude extract;

[0044] Concentrate the crude extract to a thick paste with a rotary evaporator, and dry it in a vacuum oven for 24 hours to obtain the crude extract.

[0045] Take above-mentioned crude thing by weighing, adopt anhydrous methanol to dissolve, after dilution, adopt high performance liquid chromatography to measure Prunella vulgaris rosmarinic acid, and according to rosmarinic acid yield Y=[(rosmarinic acid content × extract weight) / Prunella vulgaris medicinal material weight]×100%. The calculated yield of rosmarinic acid was 23.79 mg / g.

Embodiment 3

[0047] drying and crushing Prunella vulgaris into 60 meshes to obtain Prunella vulgaris powder;

[0048] Weigh 20.0000g of Prunella vulgaris powder, add acetic acid-sodium acetate buffer solution, enzymatically hydrolyze for 2 hours under the conditions of enzymolysis temperature 50°C, enzymolysis pH value 5.0, cellulase dosage 16mg / g, and filter the enzymolysis material , to obtain crude extract;

[0049] Concentrate the crude extract to a thick paste with a rotary evaporator, and dry it in a vacuum oven for 24 hours to obtain the crude extract.

[0050] Take above-mentioned crude thing by weighing, adopt anhydrous methanol to dissolve, after dilution, adopt high performance liquid chromatography to measure Prunella vulgaris rosmarinic acid, and according to rosmarinic acid yield Y=[(rosmarinic acid content × extract weight) / Prunella vulgaris medicinal material weight]×100%. The calculated yield of rosmarinic acid was 26.13mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com