A method for recovering tannic acid from rosin production wastewater

A technology for the production of wastewater and tannic acid, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of rosin production wastewater that is difficult to treat and cannot meet the discharge standards, so as to improve biodegradability and reduce treatment Difficulty, the effect of reducing the load of biochemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

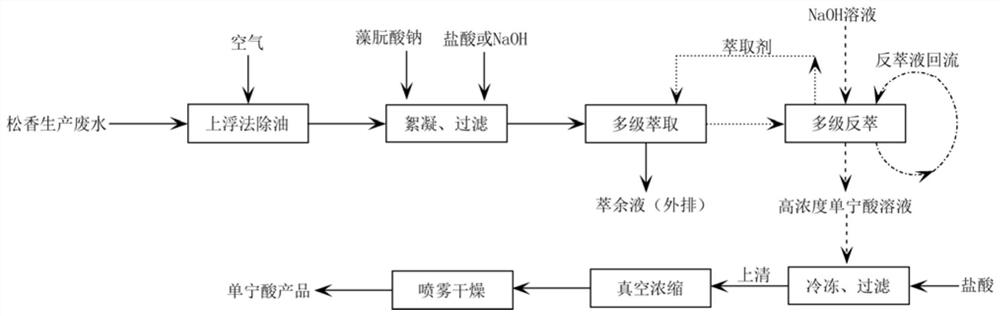

Method used

Image

Examples

Embodiment 1

[0028] (1) Put the rosin production waste water into the container, and carry out the float method aeration and degreasing with the air-water ratio of 3:1;

[0029] (2) Add hydrochloric acid in the waste water after degreasing, adjust its pH to be 5;

[0030] (3) Add sodium alginate flocculant to the wastewater after pH adjustment, the addition amount is 3g / L, the flocculation time is 10min, and filter after flocculation;

[0031] (4) the filtrate after the flocculation treatment and the dimethylheptyl methylphosphonate extractant carry out the multistage countercurrent extraction that the total number of stages is 6 to reclaim tannic acid, the volume ratio of dimethylheptyl methylphosphonate and waste water The ratio is 1:1, and after extraction, an extract containing 10g / L of tannic acid is obtained;

[0032] (5) the extract that step (4) obtains contains tannic acid and the NaOH solution that mass concentration is 20% carries out total number of stages and is 6 grades of m...

Embodiment 2

[0037] According to the method for reclaiming tannic acid from the rosin production wastewater described in Example 1, changing the addition of sodium alginate to the wastewater is 1g / L, and all the other process conditions are constant, and the recovery of the tannic acid product with a purity of 80%.

Embodiment 3

[0039] According to the method for recovering tannic acid from rosin production wastewater described in Example 1, the volume ratio of dimethylheptyl methylphosphonate and wastewater is changed to 1:3, and the rest of the process conditions are unchanged to obtain tannic acid with a purity of 76%. product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com