Corn starch pretreatment-unusual medium magnetic separation process

A corn starch and pretreatment technology, applied in magnetic separation, high gradient magnetic separator, solid separation, etc., can solve the problems of loss of iron ore resources, sorting of difficult mineral resources, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

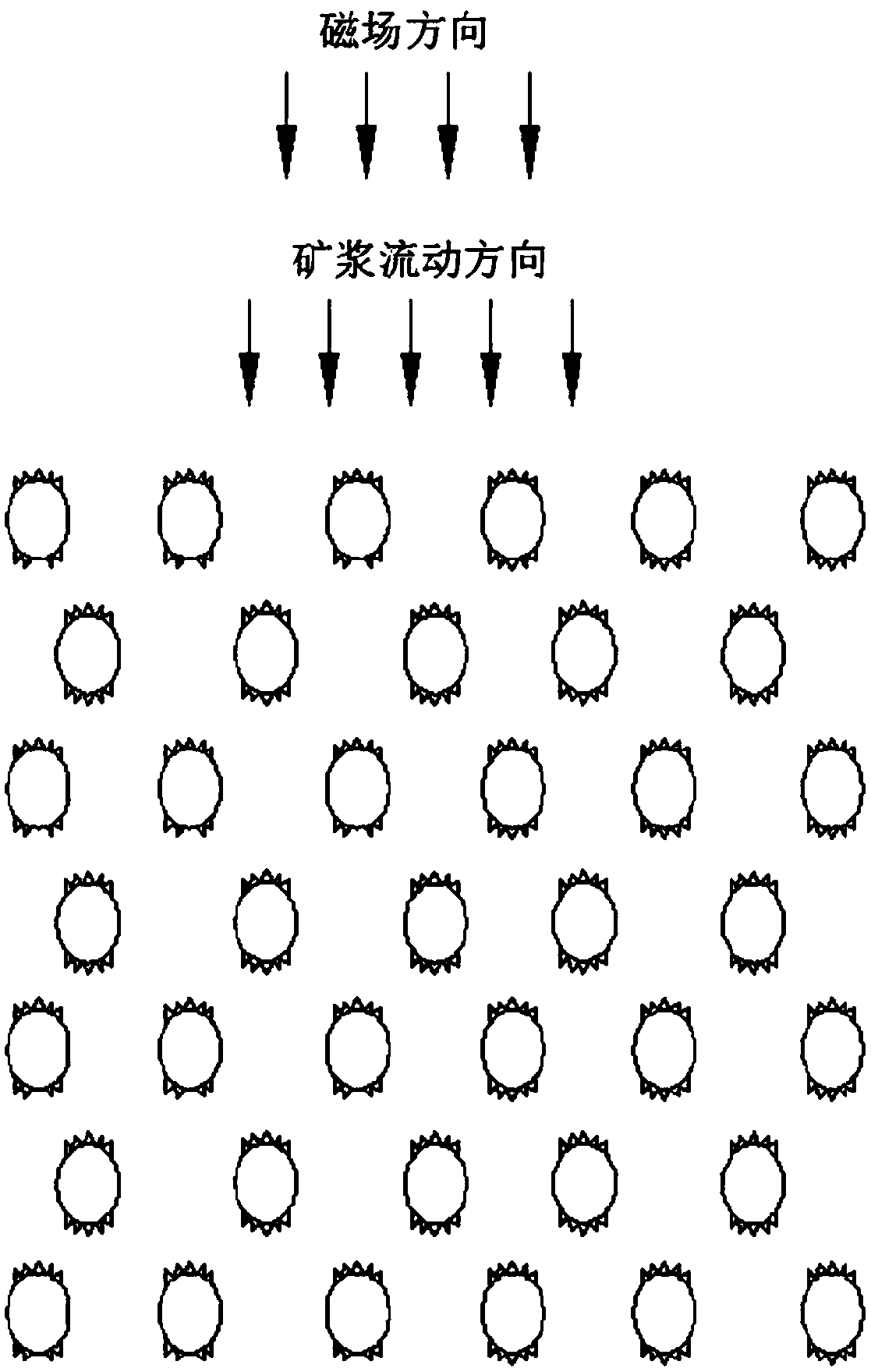

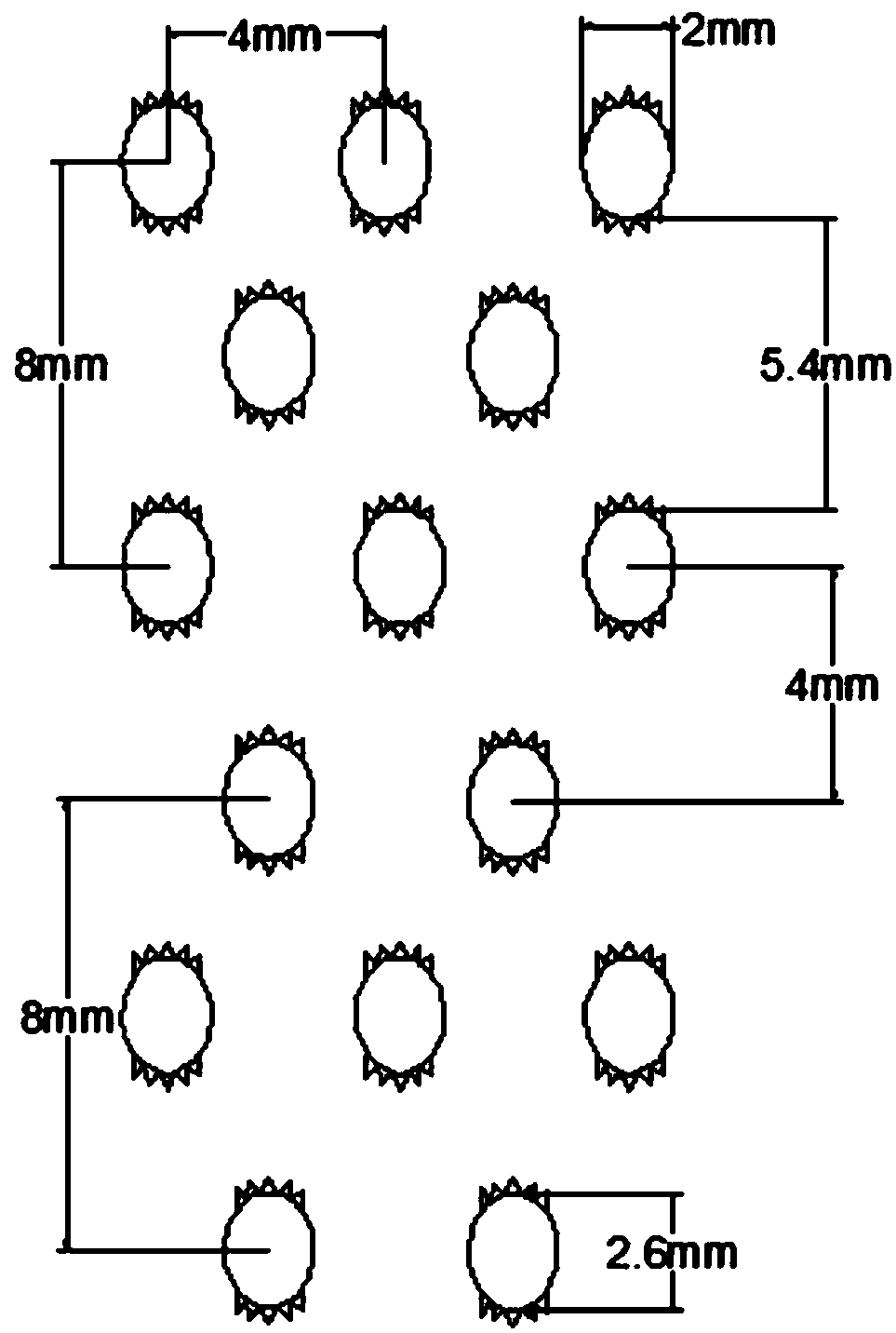

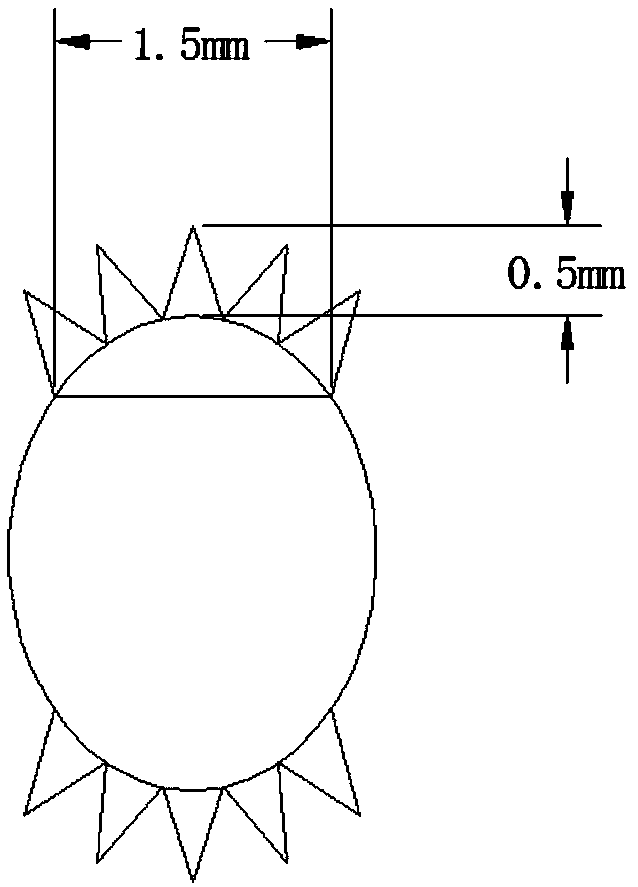

Image

Examples

Embodiment 1

[0033] (1) Get two parts of TFe grades and be respectively 26.85%, 26.71%, concentration is 33%, particle size is - 0.038mm accounts for more than 95% ore pulp containing weak magnetic iron minerals, under the condition that stirring speed is 1000r / min, add The NaOH solution with a mass concentration of 2% was stirred at a constant speed for 5 minutes, and the pH value of the pulp was adjusted to 10.0.

[0034] (2) Reduce the stirring speed to 650r / min, add cornstarch solution which has selective flocculation effect on iron minerals to the two pulps, and stir at a constant speed for 5min, so that the iron minerals in the pulp can pass through the bridging effect of cornstarch Weakly magnetic iron mineral flocs with certain strength and moderate size are formed, thereby increasing the capture probability of iron minerals in the magnetic separation process, wherein the mass ratio of the pulp to cornstarch solution is 60:1.

[0035] (3) One part of the pulp is fed to the vertical...

Embodiment 2

[0038] (1) Get two parts of TFe grades and be respectively 26.85%, 26.71%, concentration is 33%, particle size is - 0.038mm accounts for more than 95% ore pulp containing weak magnetic iron minerals, under the condition that stirring speed is 1000r / min, add The NaOH solution with a mass concentration of 2% was stirred at a constant speed for 5 minutes, and the pH value of the pulp was adjusted to 9.5.

[0039] (2) Reduce the stirring speed to 650r / min, add cornstarch solution which has selective flocculation effect on iron minerals to the two pulps, and stir at a constant speed for 5min, so that the iron minerals in the pulp can pass through the bridging effect of cornstarch Weakly magnetic iron mineral flocs with certain strength and moderate size are formed, thereby increasing the capture probability of iron minerals in the magnetic separation process, wherein the mass ratio of the pulp to cornstarch solution is 40:1.

[0040] (3) One part of the pulp is fed to the vertical ...

Embodiment 3

[0043] (1) Get two parts of TFe grades and be respectively 26.85%, 26.77%, concentration is 30%, particle size is - 0.038mm accounts for more than 95% ore pulp containing weak magnetic iron minerals, under the condition that stirring speed is 1000r / min, add The NaOH solution with a mass concentration of 2% was stirred at a constant speed for 5 minutes, and the pH value of the slurry was adjusted to 9.0.

[0044] (2) Reduce the stirring speed to 600r / min, add cornstarch solution to one part of the pulp, and stir at a constant speed for 5min, so that the iron minerals in the pulp can form a weak magnetic iron with a certain strength and a moderate size through the bridging effect of cornstarch. Mineral flocs, thereby increasing the capture probability of iron minerals in the magnetic separation process, wherein the mass ratio of the pulp to the cornstarch solution is 40:1; the other part of the pulp does not add cornstarch solution, and stirs at a constant speed for 5min .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com