Lignin and histidine drug-loaded nanoparticle with pH response and preparation method of lignin and histidine drug-loaded nanoparticle

A drug-loading nanometer and histidine technology, which is applied in the fields of biomedicine and polymer nanomaterials, can solve the problems of less application and research, and achieve the effects of reducing low toxicity, realizing intelligent controlled release, and improving drug stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Amination of alkali lignin: Weigh 5g of alkali lignin, fully dissolve it in 50mL of water to form an aqueous solution of alkali lignin, add 6g of diethylenetriamine (DETA), adjust the pH to 12, and then slowly add 4.7mL of 37% formaldehyde dropwise solution. After the dropwise addition was completed, the temperature was raised to 60° C., and the reaction was carried out for 4 hours. After the reaction, adjust the acidity with 25% sulfuric acid to precipitate the aminated lignin, collect the precipitate after centrifugation, dialyze for 36 hours, and freeze-dry for 48 hours to obtain the aminated lignin.

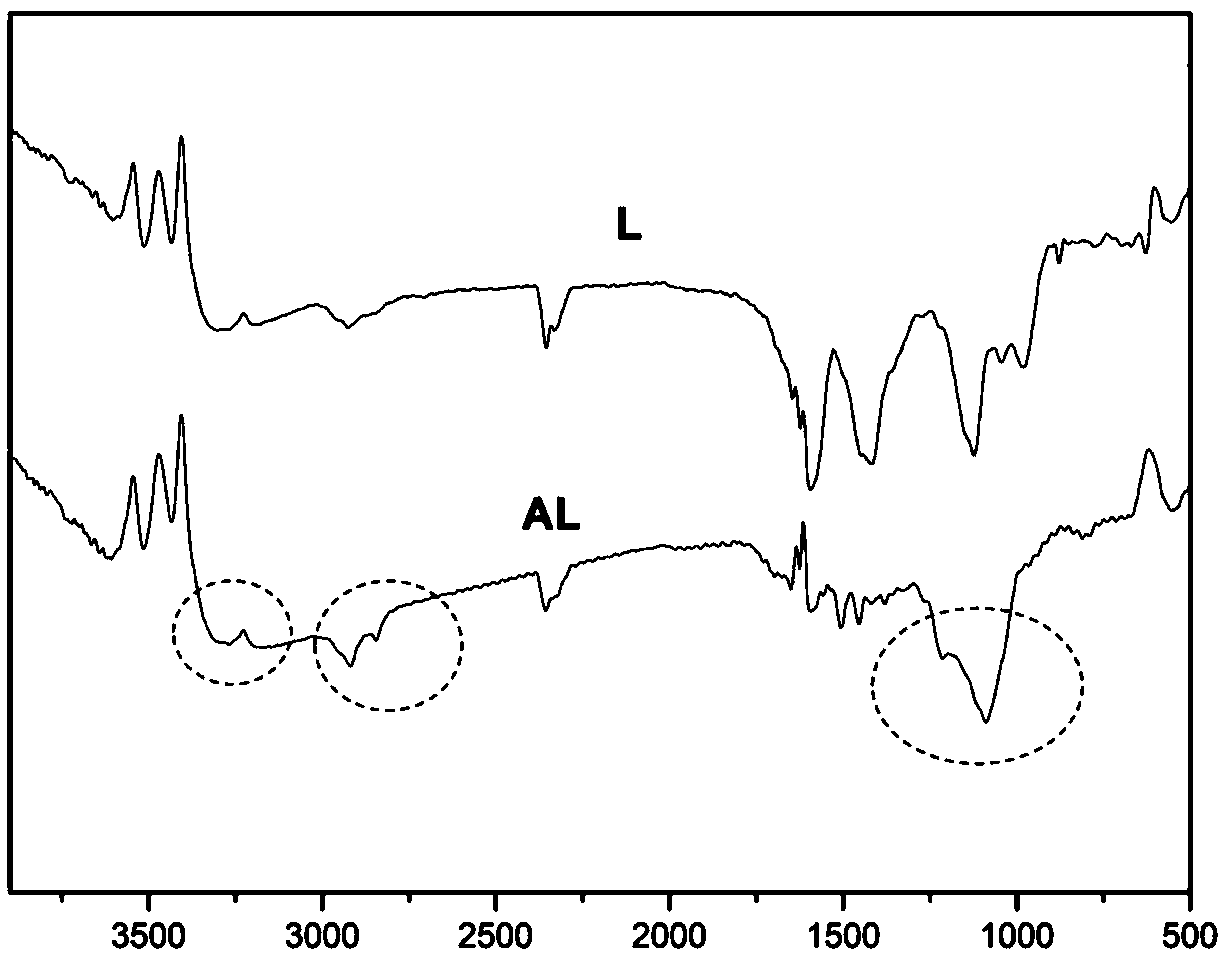

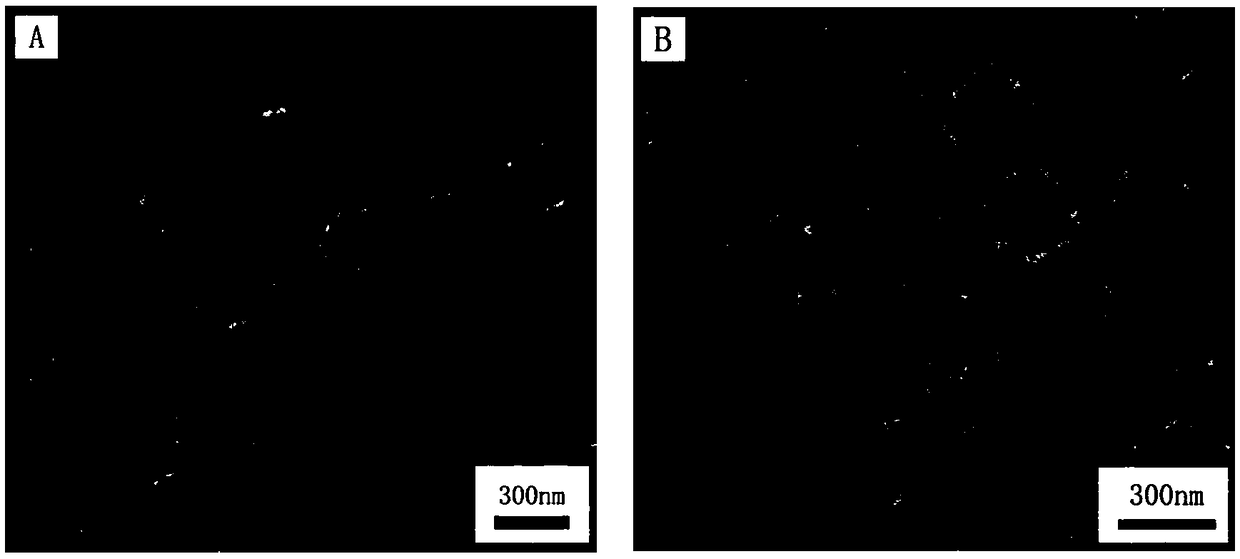

[0022] Synthesis of lignin-histidine: Take 10 mg of aminated lignin, dissolve it in 10 mL of water, make it completely dissolved, add 7.12 mg of EDC and 4.28 mg of NHS, mix well, add 5.76 mg of histidine, stir magnetically, and keep at room temperature Under the reaction 3h. After the reaction, it was dialyzed in deionized water for 24 hours, and freeze-dried to obta...

Embodiment 2

[0025] Amination of alkali lignin: Weigh 3g of alkali lignin, fully dissolve it in 50mL of water to form an aqueous alkali lignin solution, add 3.6g of diethylenetriamine (DETA), adjust the pH to 12, and then slowly add 2.8mL of 37% formaldehyde solution. After the dropwise addition was completed, the temperature was raised to 60° C., and the reaction was carried out for 4 hours. After the reaction, adjust the acidity with 25% sulfuric acid to precipitate the aminated lignin, collect the precipitate after centrifugation, dialyze for 36 hours, and freeze-dry for 48 hours to obtain the aminated lignin.

[0026] Synthesis of lignin-histidine: Take 6 mg of aminated lignin, dissolve it in 10 mL of water, make it completely dissolved, add 4.27 mg of EDC and 2.57 mg of NHS, mix well, add 3.46 mg of histidine, stir magnetically, and keep at room temperature Under the reaction 3h. After the reaction, it was dialyzed in deionized water for 24 hours, and freeze-dried to obtain the lign...

Embodiment 3

[0029] Amination of alkali lignin: Weigh 4g of alkali lignin, fully dissolve it in 50mL of water to form an aqueous solution of alkali lignin, add 4.8g of diethylenetriamine (DETA), adjust the pH to 12, and then slowly add 3.8mL of 37% formaldehyde solution. After the dropwise addition was completed, the temperature was raised to 60° C., and the reaction was carried out for 4 hours. After the reaction, adjust the acidity with 25% sulfuric acid to precipitate the aminated lignin, collect the precipitate after centrifugation, dialyze for 36 hours, and freeze-dry for 48 hours to obtain the aminated lignin.

[0030] Synthesis of lignin-histidine: take 4 mg of aminated lignin, dissolve it in 10 mL of water, make it completely dissolved, add 2.85 mg of EDC and 1.71 mg of NHS, mix well, add 2.31 mg of histidine, stir magnetically, and keep at room temperature Under the reaction 3h. After the reaction, it was dialyzed in deionized water for 24 hours, and freeze-dried to obtain the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com