Red date shortbread and processing method thereof

A technology of jujube and jujube pulp, which is applied in baking, dough processing, baked food, etc. It can solve the problems of adverse effects on human health, no removal of sour taste, and shortened shelf life, so as to improve the taste and subsequent absorption. Surface area, the effect of increasing the content of nutrient elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

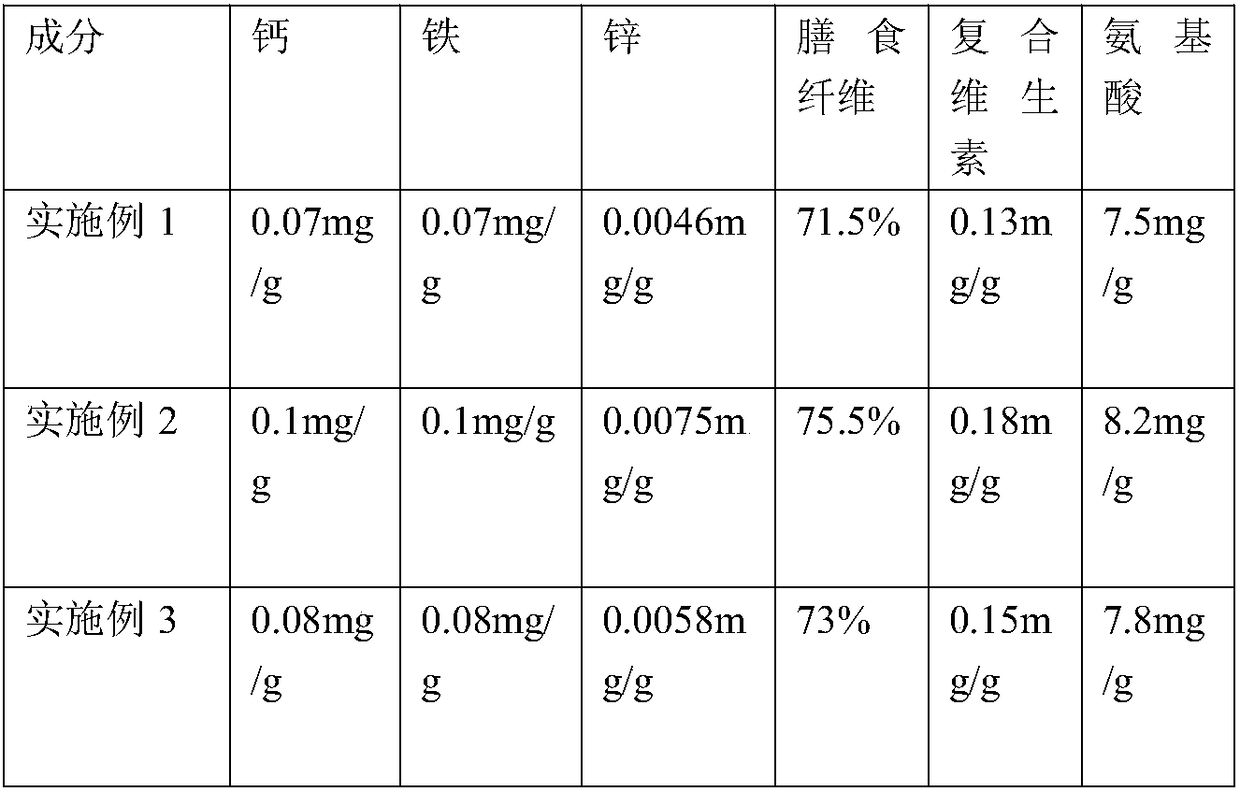

Examples

Embodiment 1

[0059] A kind of red date crisp, the specific processing method steps are as follows:

[0060] (1) Preparation of compound jam: mix and homogenize the hawthorn pulp and red date pulp, add 30 parts of white sugar and 5 parts of white powder after homogenization, stir evenly until thick, add 20 parts of butter, and mix evenly to obtain a compound jam;

[0061] (2) Compound jam compounding: compound the compound jam of step (1), add 10 parts of non-metal hydrogel composite microcapsule nutrient particles, 10 parts of metal nutrient powder, 10 parts of sweet and sour capsules, 0.5 part of antiseptic Sustained-release capsules;

[0062] (3) Preparation of red dates powder: After washing 50 parts of red dates, remove the pits, cut into pieces, and place at a temperature of 100°C and a pressure of 1.2×10 5 Treat for 40 minutes under high temperature and high pressure conditions, add 0.15% cellulase and 0.25% pectinase, carry out enzymatic hydrolysis reaction at 30℃, put the reacted red date...

Embodiment 2

[0100] A kind of red date crisp, the specific processing method steps are as follows:

[0101] (1) Preparation of compound jam: mix and homogenize hawthorn pulp and red date pulp, add 50 parts of white sugar and 10 parts of white powder after homogenization, stir evenly until thick, add 30 parts of butter, and mix evenly to obtain compound jam;

[0102] (2) Compound jam compounding: compound the compound jam of step (1), adding 20 parts of non-metal hydrogel compound microcapsule nutrient particles, 20 parts of metal nutrient powder, 20 parts of sweet and sour capsules, 1.5 parts of antiseptic Sustained-release capsules;

[0103] (3) Preparation of red date powder: After washing 100 parts of red dates, remove the pits, cut into pieces, and place at a temperature of 150°C and a pressure of 2.4×10 5 Treat for 70min under Pa high temperature and high pressure conditions, add 0.5% cellulase, 0.5% pectinase, carry out enzymolysis reaction at 45℃, put the reacted red jujube into the temper...

Embodiment 3

[0141] A kind of red date crisp, the specific processing method steps are as follows:

[0142] (1) Preparation of compound jam: mix and homogenize the hawthorn pulp and red date pulp, add 40 parts of white sugar and 7 parts of white powder after homogenization, mix evenly until thick, add 25 parts of butter, and mix evenly to obtain a compound jam;

[0143] (2) Compound jam compounding: compound the compound jam of step (1), adding 15 parts of non-metal hydrogel compound microcapsule nutrient particles, 15 parts of metal nutrient powder, 15 parts of sweet and sour capsules, 1 part of antiseptic Sustained-release capsules;

[0144] (3) Preparation of jujube powder: After washing 80 parts of jujube, remove the core, cut into pieces, and place at a temperature of 120°C and a pressure of 1.9×10 5 Treat for 55min under Pa high temperature and high pressure conditions, add 0.25% cellulase, 0.35% pectinase, carry out enzymolysis reaction at 40℃, put the reacted red jujube in temperature 65℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com