Icing adhesion strength testing device

A technology of adhesion strength and testing device, applied in the direction of measuring device, mechanical device, instrument, etc., can solve the problems of difficult operation, complicated equipment, uncertain position of ice breaking, etc., and achieve good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

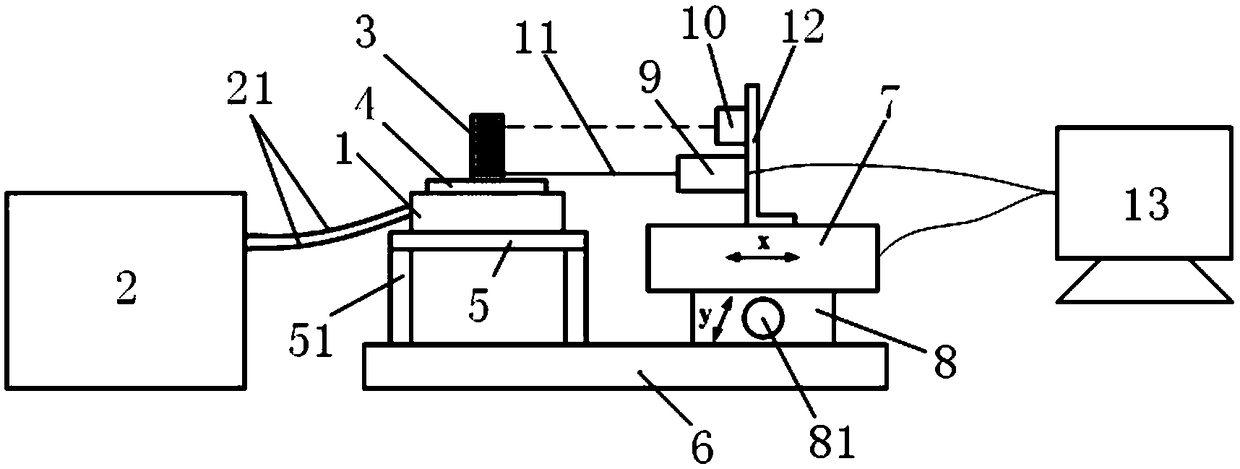

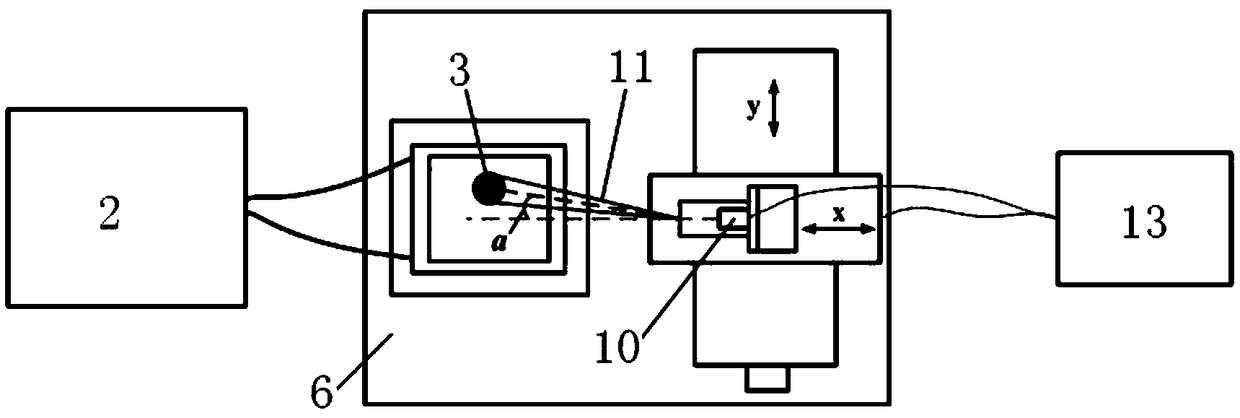

[0045] In embodiment 1 of the present invention, as Figure 1-2 As shown, the load measuring element is a tension gauge 9. When applying tension, keep the axial direction of the tension gauge 9 at the same height as the center plane of the connecting rope sleeve 11 and the axial direction of the tension gauge 9 is at the same height as The central axis of the sleeve 3 is in the same vertical plane to ensure the accuracy of the test results.

[0046] In order to facilitate the adjustment of the axial displacement of the tension gauge 9, one side of the cold table 1 is provided with a lateral movement platform 7 that can drive the tension gauge 9 to move along its axial direction (X direction), and the tension gauge 9 passes through the support 12 is installed on the described lateral movement platform 7.

[0047] Specifically, the bracket 12 is a right-angle bracket 12, and the right-angle bracket 12 includes a horizontal section and a vertical section, the horizontal section ...

Embodiment 2

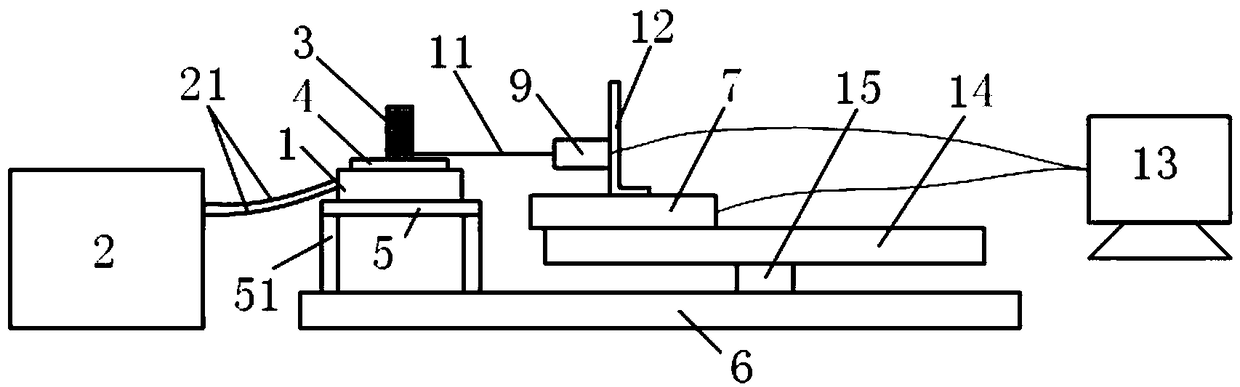

[0054] Such as Figure 3-4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the longitudinal moving platform 8 is replaced by a turntable 14 that can freely rotate around the z-axis. Specifically, a rotatable turntable 14 is provided below the horizontal moving platform 7, so The center of the turntable 14 is connected to the base 6 through a vertically arranged rotating shaft 15; the axial direction of the tension gauge 9, the centerline of the turntable 14 and the central axis of the sleeve 3 are located in the same vertical plane . An electric translation platform is installed at the edge of the turntable 14, so that the projection line of the axis of the tension meter 9 in the horizontal plane passes through the center of the turntable, and at the same time, it is ensured that the connection point where the wire rope is wrapped on the tension meter 9 within the entire movement amount of the electric translation platform P does not cross the center of...

Embodiment 3

[0056] In this example, if Figure 5-6 As shown, the load-measuring element is a torque sensor 17, and the torque sensor 17 is arranged on a turntable 16. This embodiment adopts an electric turntable 16, and the center of the turntable 16 is located above the torque sensor 17. There is a roller 18 that can rotate with the rotating table 16, and the torque sensor 17 is connected with the connecting rope 11 through the roller 18, and is used for retracting the connecting rope 11. One end of the connecting rope 11 is connected to the The wheel edges of the rollers 18 are connected tangentially. Adjust the installation height of the roller 18 so that the central symmetrical plane of the roller 18 is at the same height as the center plane of the draw groove 31 of the sleeve 3; One end is fixed on the roller 18; the rotation speed and angle of rotation of the electric rotary table 16 are set through a computer program, the electric rotary table 16 is started, and the steel wire rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com