Outdoor parallel flow heat exchanger for heat pump air conditioner

A technology of parallel flow heat exchanger and heat pump air conditioner, which is applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low heat exchange efficiency, reduced system refrigeration capacity, and heavy weight, etc., to achieve Good pressure resistance, small product volume, and improved life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

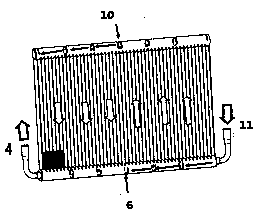

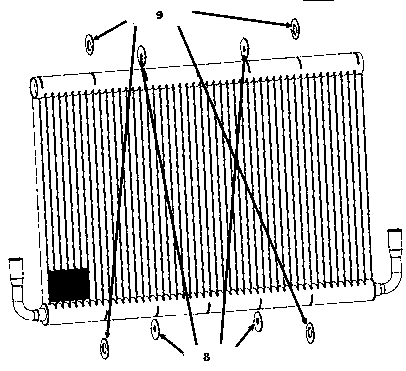

[0030] The core of the present invention is to design a parallel-flow heat exchanger. The outdoor parallel-flow heat exchanger adopts a vertical-flow, left-right symmetrical structure, and the refrigerant can flow in the forward and reverse directions. Applied in heat pump air conditioners, when the air conditioning system requires refrigeration, this product embodies the function of condenser, see figure 1 ; When the air conditioning system requires heating, this product embodies the function of the evaporator, see figure 2 .

[0031] In order to make those skilled in the art better understand the technical scheme of the present invention, the following in conjunction with the attached Figure 1-12 And specific embodiment is described in further detail to the implementation of the present invention:

[0032] An outdoor parallel flow heat exchanger for a heat pump air conditioner of the present invention mainly includes the following parts: lower header 1, multi-channel fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com